没有合适的资源?快使用搜索试试~ 我知道了~

首页NFPA68-2018标准关于爆炸防护通过传播火焰排气的重要通知和免责声明

NFPA68-2018标准关于爆炸防护通过传播火焰排气的重要通知和免责声明

需积分: 0 18 下载量 34 浏览量

更新于2023-11-24

1

收藏 19.3MB PDF 举报

《NFPA68-2018爆破透风防护标准》重要通知及免责声明

《NFPA68-2018爆破透风防护标准》是由美国国家标准协会(ANSI)批准的,采用共识标准开发程序制定而成。该程序汇集了代表不同观点和利益的志愿者,旨在就火灾和其他安全问题达成共识。尽管NFPA管理该程序并制定规则以促进共识发展过程中的公正,但其不独立测试、评估或验证NFPA标准中任何信息的准确性或判断的合理性。

NFPA对使用NFPA标准所引发的责任免责声明如下:

1. NFPA标准仅为参考目的而提供,具体使用时应适应特定情况和要求,并遵守适用的法律法规、建筑规范和安全标准等。

2. 标准中的任何建议、指南或信息并非具有强制性,用户应根据具体情况和专业知识进行独立判断,并自行承担风险。

3. NFPA不承担因使用或未能使用NFPA标准而引起或与之相关的任何责任,包括但不限于直接损失、间接损失、惩戒性损害、数据丢失或任何其他经济损失。

4. NFPA标准未涉及的其他因素,包括但不限于产品性能、材料或设备的安全、适用性以及合规性问题,应另行考虑。

5. 本声明适用于NFPA标准的所有版本。

总之,根据NFPA68-2018爆破透风防护标准的相关通知和免责声明,使用该标准时,用户应理解其只是作为参考,并在考虑特定情况和要求的基础上,独立判断和承担风险。NFPA不对任何直接或间接的损失负责,并建议用户在使用之前仔细阅读标准,并考虑其他相关因素。

FUNDAMENTALS

OF

VENTING

OF

DEFLAGRATIONS

68-13

the

resulting

damage

is

acceptable

to

the

user

and

the

author

ity

having

jurisdiction.

6.4.5

*

The

owner/user

shall

be

permitted

to

install

vents

that

are

larger

in

area,

are

lower

in

density,

or

relieve

at

lower

pres

sure

than

the

minimum

requirements

determined

from

appli

cation

of

Chapter

7

or

Chapter

8,

as

appropriate.

6.5

Vent

Closure

Operation.

6.5.1

*

The

vent

opening

shall

be

free

and

clear.

6.5.2

Vent

closure

operation

shall

not

be

hindered

by

deposits

of

snow,

ice,

paint,

corrosion,

or

debris,

or

by

the

buildup

of

deposits

on

their

inside

surfaces.

6.5.2.1

*

The

materials

that

are

used

shall

be

chosen

to

mini

mize

corrosion

from

process

conditions

within

the

enclosure

and

from

ambient

conditions

on

the

nonprocess

side.

6.5.2.2

Clear

space

shall

be

maintained

on

both

sides

of

a

vent

to

enable

operation

without

restriction

and

without

impeding

a

free

flow

through

the

vent.

6.5.2.3

To

prevent

snow

and

ice

accumulation,

where

the

potential

exists,

and

to

prevent

entry

of

rainwater

and

debris,

the

vent

or

vent

duct

exit

shall

not

be

installed

in

the

horizon

tal

position,

unless

any

of

the

alternative

methods

in

6.523.1

are

followed.

6.5.2.3.1

Any

of

the

following

alternative

methods

of

protec

tion

for

horizontal

vent

or

vent

duct

exits

shall

be

permitted:

(1)

Fixed

rain

hats

where

P

red

effects

on

vent

area

are

inclu

ded

in

accordance

with

Section

8.5

and

restraint

design

includes

maximum

force

from

P

red

applied

over

the

area

(2)

Weather

covers

mounted

at

an

angle

sufficient

to

shed

snow,

with

restraints

designed

and

tested

to

prevent

the

cover

from

becoming

a

free

projectile,

where

inertia

effects

of

the

additional

weather

cover

mass

and

P

stat

of

the

cover

are

included

(3)

Deicing

provisions

such

as

a

heated

vent

closure

6.5.3

Restraining

devices

shall

not

impede

the

operation

of

the

vent

or

vent

closure

device.

(See

Chapter

10.)

6.5.4

A

vent

closure

shall

release

at

its

P

stat

or

within

a

pressure

range

specified

by

the

vent

closure

manufacturer.

6.5.5

A

vent

closure

shall

reliably

withstand

pressure

fluctua

tions

that

are

below

P

stat

.

6.5.6

A

vent

closure

shall

withstand

vibration

or

other

mechanical

forces

to

which

it

can

be

subjected.

6.5.7

*

Pstat

,

including

the

manufacturer's

negative

tolerance,

shall

be

greater

than

the

anticipated

loading

equivalent

to

the

local

design

wind

speed

such

that

wind

load

will

not

cause

the

vent

to

open.

6.5.7.1

The

area

calculation

shall

be

performed

using

the

nominal

value

of

P

stat

.

6.5.8

*

Pstg

including

the

manufacturer's

positive

tolerance,

shall

be

less

than

the

intended

P

red

.

6.5.8.1

The

area

calculation

shall

be

performed

using

the

nominal

value

of

P

stat

.

6.5.9

*

Vent

closures

shall

be

maintained

in

accordance

with

Chapter

11.

6.6

*

Consequences

of

a

Deflagration.

6.6.1

The

material

discharged

from

an

enclosure

during

the

venting

of

a

deflagration

shall

be

directed

outside

to

a

safe

location.

6.6.2

Property

damage

and

injury

to

personnel

due

to

mate

rial

ejection

during

venting

shall

be

minimized

or

avoided

by

locating

vented

equipment

outside

of

buildings

and

away

from

normally

occupied

areas.

(See

Sections

7.6

and

8.9

for

gases

and

dusts,

respectively.)

6.6.2.1

Deflagration

vents

shall

not

be

located

in

positions

closer

to

air

intakes

than

the

distances

prescribed

by

the

fire

ball

length

(see

Sections

7.6

and

8.9).

6.6.2.2

Deflagration

vents

shall

be

permitted

to

be

located

closer

to

buildings

and

normally

occupied

areas

than

the

distances

determined

by

Section

7.6

or

Section

8.9,

provided

;

a

documented

risk

assessment

acceptable

to

the

authority

having

jurisdiction

has

been

performed.

662.3

*

Where

a

deflector

is

provided

in

accordance

with

6.6.2.4

and

6.625,

it

shall

be

permitted

to

reduce

the

axial

(front-centerline)

hazard

distance

to

50

percent

of

the

value

calculated

in

7.6.1

or

8.9.2.

This

method

shall

not

be

used

to

reduce

the

radial

hazard

distance

as

defined

in

7.6.2

and

8.922

[115].

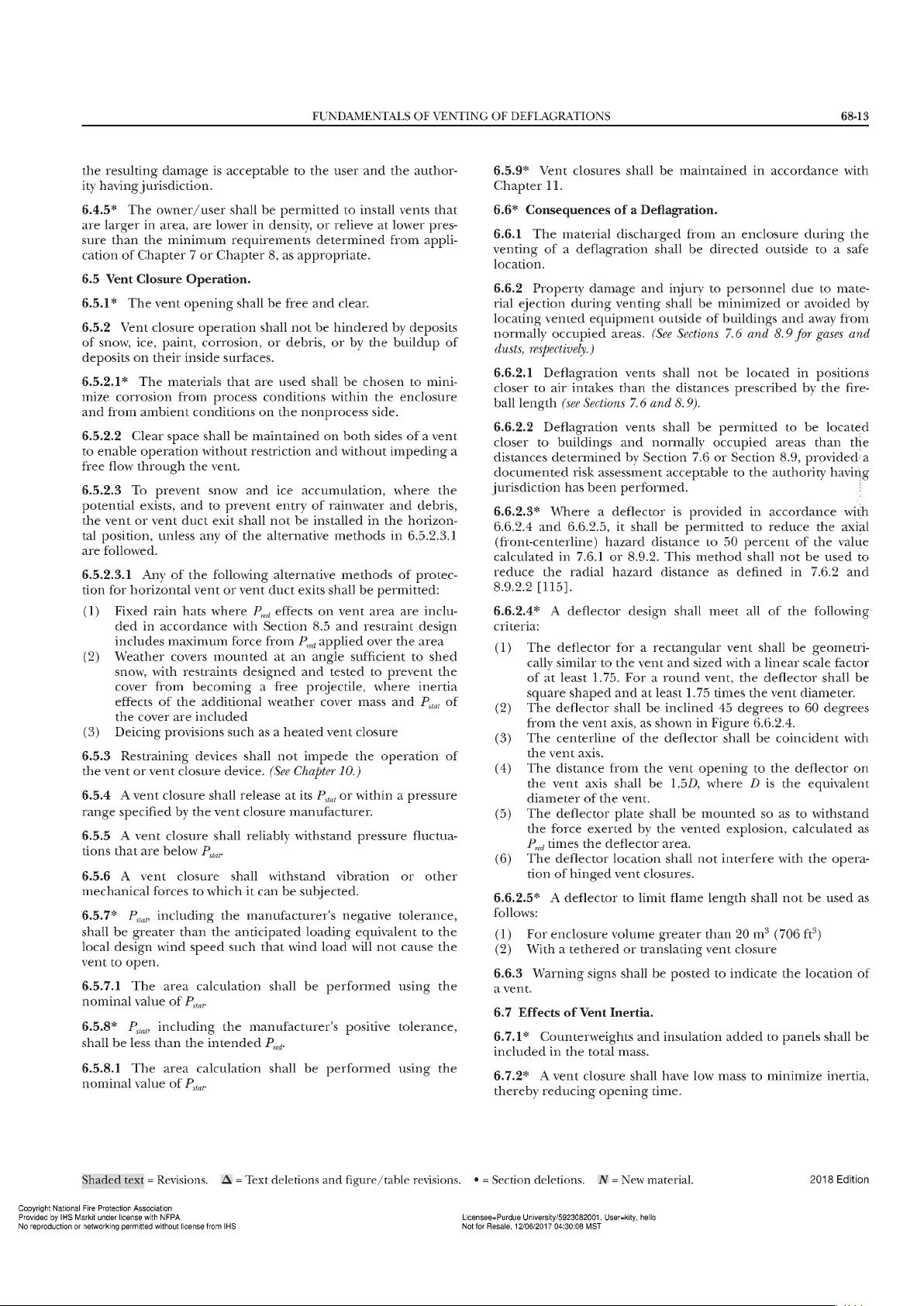

6.6.2.4

*

A

deflector

design

shall

meet

all

of

the

following

criteria:

(1)

The

deflector

for

a

rectangular

vent

shall

be

geometri

cally

similar

to

the

vent

and

sized

with

a

linear

scale

factor

of

at

least

1.75.

For

a

round

vent,

the

deflector

shall

be

square

shaped

and

at

least

1.75

times

the

vent

diameter.

(2)

The

deflector

shall

be

inclined

45

degrees

to

60

degrees

from

the

vent

axis,

as

shown

in

Figure

6.624.

(3)

The

centerline

of

the

deflector

shall

be

coincident

with

the

vent

axis.

(4)

The

distance

from

the

vent

opening

to

the

deflector

on

the

vent

axis

shall

be

1.57),

where

D

is

the

equivalent

diameter

of

the

vent.

(5)

The

deflector

plate

shall

be

mounted

so

as

to

withstand

the

force

exerted

by

the

vented

explosion,

calculated

as

P

red

times

the

deflector

area.

(6)

The

deflector

location

shall

not

interfere

with

the

opera

tion

of

hinged

vent

closures.

6.6.2.5

*

A

deflector

to

limit

flame

length

shall

not

be

used

as

follows:

(1)

For

enclosure

volume

greater

than

20

m

3

(706

ft

3

)

(2)

With

a

tethered

or

translating

vent

closure

6.6.3

Warning

signs

shall

be

posted

to

indicate

the

location

of

a

ven

匚

6.7

Effects

of

Vent

Inertia.

6.7.1

*

Counterweights

and

insulation

added

to

panels

shall

be

included

in

the

total

mass.

6.7.2

*

A

vent

closure

shall

have

low

mass

to

minimize

inertia,

thereby

reducing

opening

time.

Shaded

text

=

Revisions.

△

=

Text

deletions

and

figure/table

revisions.

•

=

Section

deletions.

N

=

New

material.

68-14

EXPLOSION

PROTECTION

BY

DEFLAGRATION

VENTING

FIGURE

6.6.2.4

Design

for

an

Installation

of

a

Blast

Deflector

Plate.

6.7.3

If

the

total

mass

of

a

closure

divided

by

the

area

of

the

vent

opening

does

not

exceed

the

panel

densities

calculated

by

Equation

7.3.2

and

Equation

8.3.2

(for

gas

and

dust,

respec

tively)

,

all

vent

area

correlations

presented

in

this

standard

shall

be

permitted

to

be

used

without

correction

[111].

6.7.4

*

Hinged

closures

shall

be

permi

仕

ed

to

be

used,

provi

ded

the

following

conditions

are

met:

(1)

There

are

no

obstructions

in

the

path

of

the

closure

that

prevent

it

from

opening.

(2)

Operation

of

the

closure

is

not

restrained

by

corrosion,

sticky

process

materials,

or

paint.

6.8

Effects

of

Vent

Discharge

Ducts.

6.8.1

If

it

is

necessary

to

locate

enclosures

with

deflagration

vents

inside

of

buildings,

vent

ducts

shall

be

used

to

direct

vented

material

from

the

enclosure

to

the

outdoors.

6.8.2

A

vent

duct

shall

have

a

cross-sectional

area

at

least

as

great

as

that

of

the

vent

itself

but

shall

be

limited

to

no

more

than

150

percent

of

the

vent

itself

at

any

point

in

the

vent

duct.

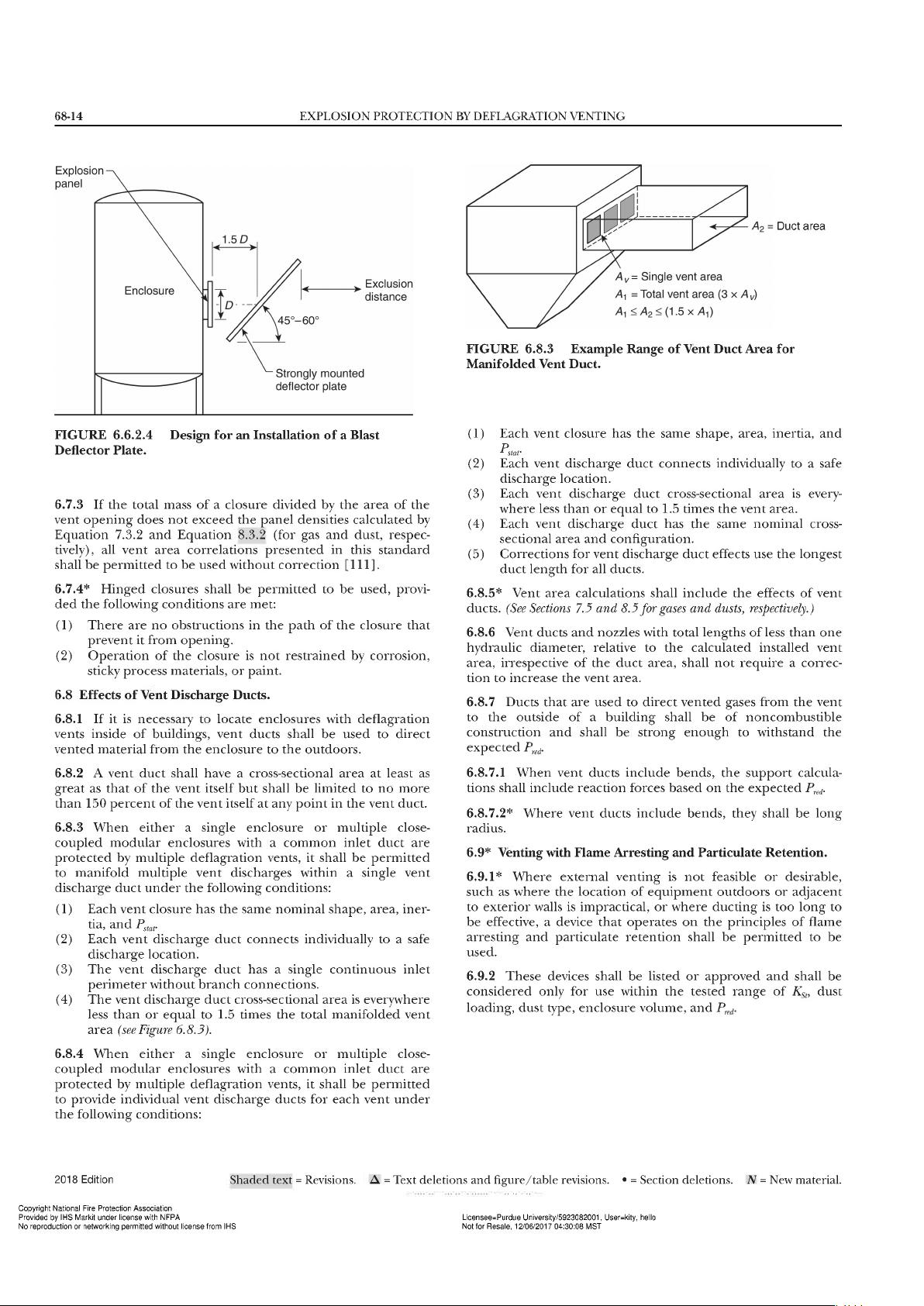

6.8.3

When

either

a

single

enclosure

or

multiple

close-

coupled

modular

enclosures

with

a

common

inlet

duct

are

protected

by

multiple

deflagration

vents,

it

shall

be

permitted

to

manifold

multiple

vent

discharges

within

a

single

vent

discharge

duct

under

the

following

conditions:

(1)

Each

vent

closure

has

the

same

nominal

shape,

area,

iner

tia,

and

P

stat

.

(2)

Each

vent

discharge

duct

connects

individually

to

a

safe

discharge

location.

(3)

The

vent

discharge

duct

has

a

single

continuous

inlet

perimeter

without

branch

connections.

(4)

The

vent

discharge

duct

cross-sectional

area

is

everywhere

less

than

or

equal

to

1.5

times

the

total

manifolded

vent

area

(see

Figure

6.8.3).

6.&4

When

either

a

single

enclosure

or

multiple

close-

coupled

modular

enclosures

with

a

common

inlet

duct

are

protected

by

multiple

deflagration

vents,

it

shall

be

permitted

to

provide

individual

vent

discharge

ducts

for

each

vent

under

the

following

conditions:

FIGURE

6.8.3

Example

Range

of

Vent

Duct

Area

for

Manifolded

Vent

Duct.

(1)

Each

vent

closure

has

the

same

shape,

area,

inertia,

and

Pstaf

(2)

Each

vent

discharge

duct

connects

individually

to

a

safe

discharge

location.

(3)

Each

vent

discharge

duct

cross-sectional

area

is

every

where

less

than

or

equal

to

1.5

times

the

vent

area.

(4)

Each

vent

discharge

duct

has

the

same

nominal

cross-

sectional

area

and

configuration.

(5)

Corrections

for

vent

discharge

duct

effects

use

the

longest

duct

length

for

all

ducts.

6.8.5

*

Vent

area

calculations

shall

include

the

effects

of

vent

ducts.

(See

Sections

7.5

and

8.5

for

gases

and

dusts,

respectively.)

6.8.6

Vent

ducts

and

nozzles

with

total

lengths

of

less

than

one

hydraulic

diameter,

relative

to

the

calculated

installed

vent

area,

irrespective

of

the

duct

area,

shall

not

require

a

correc

tion

to

increase

the

vent

area.

6.8.7

Ducts

that

are

used

to

direct

vented

gases

from

the

vent

to

the

outside

of

a

building

shall

be

of

noncombustible

construction

and

shall

be

strong

enough

to

withstand

the

expected

P

red

.

6.&7.1

When

vent

ducts

include

bends,

the

support

calcula

tions

shall

include

reaction

forces

based

on

the

expected

P

red

.

6.8.7.2

*

Where

vent

ducts

include

bends,

they

shall

be

long

radius.

6.9

*

Venting

with

Flame

Arresting

and

Particulate

Retention.

6.9.1

*

Where

external

venting

is

not

feasible

or

desirable,

such

as

where

the

location

of

equipment

outdoors

or

adjacent

to

exterior

walls

is

impractical,

or

where

ducting

is

too

long

to

be

effective,

a

device

that

operates

on

the

principles

of

flame

arresting

and

particulate

retention

shall

be

permitted

to

be

used.

6.9.2

These

devices

shall

be

listed

or

approved

and

shall

be

considered

only

for

use

within

the

tested

range

of

K

St

,

dust

loading,

dust

type,

enclosure

volume,

and

P

red

.

Shaded

text

=

Revisions.

△

=

Text

deletions

and

figure/table

revisions.

•

=

Section

deletions.

N

=

New

material.

VENTING

DEFLAGRATIONS

OF

GAS

MIXTURES

AND

MISTS

68-15

6.9.3

*

The

deflagration

venting

area

provided

for

the

protec

ted

enclosure

shall

be

increased

to

compensate

for

the

reduc

tion

in

venting

efficiency

due

to

the

presence

of

the

device.

6.9.4

*

Limitations.

The

following

limitations

shall

apply:

(1)

Where

a

flame-arresting

vent

system

and

a

particulate

retention

vent

system

are

used

inside

a

building,

a

docu

mented

risk

analysis

shall

be

performed

to

ensure

safe

installation.

Considerations

shall

include,

but

are

not

limited

to,

the

following:

(a)

Proximity

of

personnel

(b)

Volume

of

room

(c)

Possibility

of

combustible

mixtures

exterior

to

the

equipment

(d)

Possible

toxic

gaseous

and

particulate

emissions

(2)

A

flame-arresting

vent

system

and

a

particulate

retention

vent

system

shall

be

sized

to

ensure

that

P

red

remains

within

the

enclosure

design

limits.

6.9.5

*

The

areas

adjacent

to

the

discharge

point

shall

be

clear

of

combustible

dusts.

6.9.6

*

All

devices

shall

be

equipped

with

an

indicating

sensor

that

shall

notify

the

user

upon

activation

of

the

device.

6.9.7

*

Flame-arresting

vent

devices

without

particulate

reten

tion

shall

be

used

only

where

a

restricted

area

around

the

device

has

been

identified

and

access

during

operation

of

the

protected

equipment

is

prohibited.

6.9.7.1

The

restricted

area

shall

be

based

on

the

external

volume

that

can

be

filled

with

an

explosible

dust-air

cloud

during

the

venting

process.

△

6.9.7.2

The

restricted

area

shall

be

identified

as

an

electrically

classified

(hazardous)

area

in

accordance

with

NFPA

70.

6.9.7.3

There

shall

be

no

normally

present

ignition

sources

in

the

restricted

area,

including,

but

not

limited

to,

hot

surfaces

exceeding

the

auto-ignition

temperature

and

open

flames.

6.9.8

*

Devices

without

particulate

retention

elements

that

reset

after

relieving

pressure

shall

be

inspected

after

a

deflagra

tion

to

ensure

that

the

design

performance

has

not

been

affec

ted.

Chapter

7

Venting

Deflagrations

of

Gas

Mixtures

and

Mists

7.1

Introduction.

7.1.1

*

This

chapter

shall

apply

to

the

design

of

deflagration

vents

for

enclosures

that

contain

a

flammable

gas

or

combusti

ble

mist

and

that

have

an

L/D

of

<5.

7.1.1.1

This

chapter

shall

be

used

in

conjunction

with

the

information

contained

in

the

rest

of

this

standard.

△

7.1.1.2

Chapter

6

and

3.3.32.1

shall

be

reviewed

before

using

this

chapter.

■

7.2

Venting

by

Means

of

Low

Inertia

Vent

Closures.

△

7.2.1

Low

Inertia

Vent

Closure

Equations

for

Low

P

red

,

When

P

red

<

0.5

bar-g,

the

minimum

required

vent

area,

A

w0

,

shall

be

determined

by

Equation

7.2.1a

and

Equation

7.2.1b:

[7.2.1a]

[7.2.1b]

厲

严

where:

A

沁

=

the

vent

area

calculated

from

Equation

7.2.1a

(m

2

)

A

s

=

the

enclosure

internal

surface

area

determined

accord

ing

to

725

(m

2

)

P

red

=

the

maximum

pressure

developed

in

a

vented

enclosure

during

a

vented

deflagration

(bar-g)

S

u

=

fundamental

burning

velocity

of

gas-air

mixture

(m/s)

p

M

=

mass

density

of

unburned

gas-air

mixture

(kg/m

3

)

X

=

ratio

of

gas-air

mixture

burning

velocity

accounting

for

turbulence

and

flame

instabilities

in

vented

deflagration

to

the

fundamental

(laminar)

burning

velocity,

deter

mined

according

to

7.2.6

G

u

=

unburned

gas-air

mixture

sonic

flow

mass

flux

(kg/m

2

-s)

C

d

=

vent

flow

discharge

coefficient,

determined

according

to

7.2.4

P

max

=

the

maximum

pressure

developed

in

a

contained

defla

gration

by

ignition

of

the

same

gas-air

mixture

(bar-g)

Po

=

the

enclosure

pressure

prior

to

ignition

(bar-g)

=

ratio

of

specific

heats

for

burned

gas-air

mixture

7.2.1.1

The

C

value

for

flammable

gases

and

vapors

with

a

P

max

value

less

than

9

bar-g

and

a

stoichiometric

(near

worst

case)

fuel

concentration

no

greater

than

about

10

percent

shall

be

permitted

to

be

calculated

using

Equation

7.2.1.1

for

use

in

Equation

7.2.1a:

△

[7.2.1.1]

C

=

0.0223

九

S

”

bar%

for

S

u

in

m/s

7.2.1.2

When

applying

Equation

7.2.1a,

the

value

of

P

stat

shall

be

less

than

P

red

as

specified

for

the

following

conditions:

(1)

For

P

red

<

0.1

bar-g

(1.5

psig),

P

stat

<

P

red

-

0.024

bar-g

(50

psf).

(2)

For

P

说

〉

0.1

bar-g

(1.5

psig),

P

5

^<0.75

P

red

.

7.2.2

Low

Inertia

Vent

Closure

Equations

for

High

P

red

.

When

P

red

>

0.5

bar-g,

the

minimum

required

vent

area,

A

沁

,

shall

be

determined

from

Equation

7.2.2a

and

Equation

7.2.2b:

△

[7.2.2a]

Shaded

text

=

Revisions.

△

=

Text

deletions

and

figure/table

revisions.

•

=

Section

deletions.

N

=

New

material.

68-16

EXPLOSION

PROTECTION

BY

DEFLAGRATION

VENTING

[7.2.2b]

5

=

/

stat

_____

丿

[p°+l

丿

where:

=

the

vent

area

calculated

from

Equation

7.2.2a

(m

2

)

A

s

=

the

enclosure

internal

surface

area

determined

accord

ing

to

7.2.5

(m

2

)

P

red

=

the

maximum

pressure

developed

in

a

vented

enclosure

during

a

vented

deflagration

(bar-g)

S

u

=

fundamental

burning

velocity

of

gas-air

mixture

(m/s)

p

M

=

mass

density

of

unburned

gas-air

mixture

(kg/m

3

)

X

=

ratio

of

gas-air

mixture

burning

velocity

accounting

for

turbulence

and

flame

instabilities

in

vented

deflagration

to

the

fundamental

(laminar)

burning

velocity,

deter

mined

according

to

7.2.6

G

u

=

unburned

gas-air

mixture

sonic

flow

mass

flux

(kg/m

2

-s)

C

d

=

vent

flow

discharge

coefficient,

determined

according

to

724

P

max

=

the

maximum

pressure

developed

in

a

contained

defla

gration

by

ignition

of

the

same

gas-air

mixture

(bar-g)

Po

=

the

enclosure

pressure

prior

to

ignition

(bar-g)

%

=

ratio

of

specific

heats

for

burned

gas-air

mixture

P

stat

=

nominal

vent

deployment

or

burst

pressure

(bar-g)

7.2.3

*

Gas-Air

Mixture

Parameters.

N

7.2.3.1

*

The

design

of

a

deflagration

vent

for

an

enclosure

containing

a

combustible

mist

shall

be

based

on

a

value

of

S

u

equal

to

0.46

m/s

unless

a

value

of

S

u

applicable

to

the

mist

of

a

particular

substance

is

determined

by

test.

7.2.3.2

*

The

burning

velocity,

S

u

,

shall

be

the

maximum

value

for

any

gas

concentration

unless

a

documented

hazard

analysis

shows

that

there

is

not

a

sufficient

amount

of

gas

to

develop

such

a

concentration.

N

7.2.3.3

It

shall

be

permitted

to

assume

a

mass

density

of

unburned

gas-air

mixture,

p

u

,

equal

to

1.2

kg/m

3

for

flammable

gases

with

stoichiometric

concentrations

less

than

5

vol

%

and

initially

at

ambient

temperature.

N

7.2.3.4

It

shall

be

permitted

to

assume

an

unburned

gas-air

mixture

sonic

flow

mass

flux,

G

u

,

equal

to

230.1

kg/m

2

-s

for

an

enclosure

initially

at

ambient

temperatures.

N

7.2.3.5

It

shall

be

permitted

to

assume

the

ratio

of

specific

heats

for

burned

gas-air

mixture,

=

历

equal

to

1.15

for

flamma

ble

gases

with

stoichiometric

concentrations

less

than

5

vol

%

and

initially

at

ambient

temperatures.

N

7.2.3.6

It

shall

be

permitted

to

assume

the

unburned

gas-air

mixture

dynamic

velocity,

血

equal

to

1.8

x

10'

5

kg/m-s

for

flammable

gases

with

stoichiometric

concentrations

less

than

5

vol

%

and

initially

at

ambient

temperatures.

N

7.2.3.7

It

shall

be

permi

仕

ed

to

assume

the

unburned

gas-air

mixture

sound

speed,

a

u

,

equal

to

343

m/s

for

flammable

gases

with

stoichiometric

concentrations

less

than

5

vol

%

and

initially

at

ambient

temperatures.

△

7.2.4

Enclosure

Parameters.

7.2.4.1

The

value

of

C

d

shall

be

0.70

unless

the

vent

occupies

an

entire

wall

of

the

enclosure,

in

which

case

a

value

of

0.80

shall

be

permitted

to

be

used.

N

7.2.4.2

*

The

value

of

P°

shall

be

greater

than

or

equal

to

the

normal

operating

pressure

and

chosen

to

represent

the

likely

maximum

pressure

at

which

a

flammable

gas

mixture

can

exist

at

the

time

of

ignition.

N

7.2.4.3

*

For

initially

elevated

pressures,

the

enclosure

shall

be

located

to

accommodate

the

blast

wave.

7.2.5

*

Calculation

of

Internal

Surface

Area.

7.2.5.1

*

The

internal

surface

area,

A

s

,

shall

include

the

total

area

that

constitutes

the

perimeter

surfaces

of

the

enclosure

that

is

being

protected.

7.2.5.1.1

Nonstructural

internal

partitions

that

cannot

with

stand

the

expected

pressure

shall

not

be

considered

to

be

part

of

the

enclosure

surface

area.

7.2.5.1.2

The

enclosure

internal

surface

area,

A

s

,

in

Equation

7.2.2

includes

the

roof

or

ceiling,

walls,

floor,

and

vent

area

and

shall

be

based

on

simple

geometric

figures.

7.2.5.1.3

Surface

corrugations

and

minor

deviations

from

the

simplest

shapes

shall

not

be

taken

into

account.

7.2.5.1.4

Regular

geometric

deviations,

such

as

saw-toothed

roofs,

shall

be

permitted

to

be

"averaged

”

by

adding

the

contributed

volume

to

that

of

the

major

structure

and

calculat

ing

As

for

the

basic

geometry

of

the

major

structure.

7.2.5.1.5

*

The

internal

surface

of

any

adjoining

rooms

shall

be

included.

7.2

・

5.2

The

surface

area

of

equipment

and

contained

struc

tures

shall

be

neglected.

7.2.6

*

Determination

of

Turbulent

Flame

Enhancement

Factor,

X.

△

7.2.6.1

*

The

baseline

value,

X

o

,

of

X

shall

be

calculated

from

Equations

7.2.6.1a

through

7.2.6.1f:

[7.2.6.1a]

<Pi

=

1,

if

Re

y

<

4000

[7.2.6.1b]

(

)

△

[7.2.6.1c]

Shaded

text

^

Revisions.

△

=

Text

deletions

and

figure/table

revisions.

•

=

Section

deletions.

N

=

New

material.

VENTING

DEFLAGRATIONS

OF

GAS

MIXTURES

AND

MISTS

68-17

[7.2.6.

Id]

P

血

(

2/2

)

7

・

2.6

・

7

For

L/D

values

from

2.5

to

5

and

for

P

red

no

higher

than

2

bar-g,

X

shall

be

calculated

as

follows:

[7.2.6.7]

[7.2.6.

le]

九

0

=

(

P1<P

2

[7.2.6.1f]

where:

p

M

=

mass

density

of

unburned

gas-air

mixture

(kg/m

3

)

S

u

=

fundamental

burning

velocity

of

gas-air

mixture

(m/s)

D

he

=

the

enclosure

hydraulic

equivalent

diameter

as

deter

mined

in

Chapter

6

(m)

=

the

unburned

gas-air

mixture

dynamic

velocity

(kg/m-s)

=1.23

=2.37

x

IO

3

m/s

=

the

vent

diameter

as

determined

through

iterative

calcu

lation

(m)

=

maximum

velocity

through

vent

(m/s)

=

the

maximum

pressure

developed

in

a

vented

enclosure

during

a

vented

deflagration

(bar-g)

a

u

=

the

unburned

gas-air

mixture

sound

speed

(m/s|)

e

=

0.39

△

7.2.6.2

The

total

external

surface

area,

A

obs

,

of

the

following

equipment

and

internal

structures

that

can

be

in

the

enclosure

shall

be

estimated:

(1)

Piping,

tubing,

and

conduit

with

diameters

greater

than

%

in.

(2)

Structural

columns,

beams,

and

joists

(3)

Stairways

and

railings

(4)

Equipment

with

a

characteristic

dimension

in

the

range

of

2

in.

to

20

in.

(5.1

cm

to

51

cm)

7.263

When

A

obs

<

0.2A

s

,

shall

be

equal

to

X

o

as

determined

in

726.1.

7.2.6.4

When

A

obs

>

0.2A

s

,

X

x

shall

be

determined

as

follows:

九

=

入

(

L/

1

+

亠

1

2.5

<

)

7.2.6.8

Equations

for

determining

X

shall

be

subject

to

the

following

limitations:

(1)

S

u

<3

m/s

(300

cm/s)

.

⑵

P

max

<

10

bar-g.

(3)

The

maximum

air

velocity

in

the

enclosure

prior

to

igni

tion

is

no

greater

than

5

m/s.

(4)

The

enclosure

is

isolated

from

possible

flame

jet

ignition

and

pressures

caused

by

a

deflagration

in

an

interconnec

ted

enclosure.

7.2.6.9

For

long

pipes

or

process

ducts

where

L/D

is

greater

than

5,

the

requirements

of

Chapter

9

shall

be

used.

7.2.6.10

Methods

to

Reduce

Flame

Enhancement

・

7.2.6.10.1

The

value

of

X

shall

be

permitted

to

be

reduced

for

gas

deflagrations

in

relatively

unobstructed

enclosures

by

the

installation

of

noncombustible,

acoustically

absorbing

wall

linings,

provided

that

large-scale

test

data

confirm

the

reduc

tion.

7.2.6.10.2

The

tests

shall

be

conducted

with

the

highest

antici

pated

turbulence

levels

and

with

the

proposed

wall

lining

mate

rial

and

thickness.

7.3

Partial

Volume

Effects.

7.3.1

When

a

documented

hazard

analysis

demonstrates

that

there

is

insufficient

gas

in

the

enclosure

to

form

a

stoichiomet

ric

gas-air

mixture

occupying

the

entire

enclosure

volume,

the

vent

area,

A

沁

,

calculated

from

Equation

7.2.1a

or

Equation

7.2.2a,

as

appropriate,

shall

be

permitted

to

be

reduced

as

described

in

7.3.3.

7.3.2

A

partial

volume

fill

fraction,

shall

be

calculated

as

follows:

[7.3.2]

△

[7.2.6.4J

N

7.2.6.5

The

L/D

of

the

enclosure

shall

be

determined

accord

ing

to

Section

6.4.

7.2.6.6

For

L/D

values

less

than

2.5,

X

shall

be

set

equal

to

X

P

where:

V

gas

=

maximum

volume

of

gas

that

can

be

mixed

with

air

in

the

enclosure

V

enc

=

enclosure

volume

x

st

=

stoichiometric

volume

concentration

of

gas

Shaded

text

=

Revisions.

△

=

Text

deletions

and

figure/table

revisions.

•

—

Section

deletions,

N

=

New

material.

剩余99页未读,继续阅读

点击了解资源详情

点击了解资源详情

点击了解资源详情

2024-04-18 上传

2024-04-18 上传

2022-12-01 上传

2024-04-18 上传

上山砍菜

- 粉丝: 1

- 资源: 225

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

最新资源

- C语言深度解剖.pdf

- spfdisk用法,如何使用SPFDISK

- AJAX开发简略【javascript xml】

- Visual C++面向对象与可视化程序设计.pdf

- VC++动态链接库(dll)编程深入浅出.pdf

- Learning PHP, MySQL, and JavaScript

- Delphi 2009 Handbook

- jstl语法的具体应用介绍

- 《MakingThingsMove》中文版

- 微电子专业英语单词打包下载

- IA-32卷3:系统编程指南(至第8章).pdf

- zones survival guide

- mtk入门资料 很有用

- 关于反汇编与驱动编写

- DNS BIND9-CHS

- Linux驱动程序编写,欢迎大家下载

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功