4880 IEEE TRANSACTIONS ON ELECTRON DEVICES, VOL. 63, NO. 12, DECEMBER 2016

Electrical Characterization of Coaxial

Silicon–Insulator–Silicon Through-Silicon Vias:

Theoretical Analysis and Experiments

Zhiming Chen, Miao Xiong, Bohao Li, An’an Li, Yangyang Yan, and Yingtao Ding

Abstract—Coaxial through-silicon via (TSV) provides an

effective solution to achieve impedance matching, reduce trans-

mission loss, and suppress interference or noise coupling in

3-D/2.5-D heterointegrated systems. This paper presents a

fabrication friendly coaxial TSV configuration based on heav-

ily doped silicon–insulator–silicon (SIS) structure, whose elec-

trical characteristics are studied through deriving analytical

solution, performing numerical simulation, and conducting exper-

imental measurement. The distributed resistance–inductance–

capacitance–conductance (RLCG) parameters are calculated

from electromagnetic theory and semiconductor physics. Wide-

band S-parameters of the fabricated devices are obtained using

on-wafer measurement with deembedding technique, and then

compared against 3-D full-wave simulations and analytical solu-

tions, exhibiting good agreement up to 50 GHz. Results show that

the proposed coaxial SIS TSV offers flexible impedance control,

good matching, and low insertion loss, and supports 30-Gbps

data transmission with the simpler structure as well as the lower

fabrication cost compared with various coaxial TSV structures

reported to date.

Index Terms—Coaxial through-silicon via (TSV), eye dia-

gram, resistance–inductance–capacitance–conductance (RLCG)

model, silicon–insulator–silicon (SIS), 3-D ICs, wideband

S-parameters.

I. INTRODUCTION

A

3-D integration technology has attracted much atten-

tion both from the academics and industries for it can

not only provide an alternative solution to further increase

the packaging density of future electronic devices but also

facilitate heterogeneous integration of multifunctional sys-

tems [1]–[4]. As the key of 3-D integration, through-silicon

vias (TSVs) have also been studied aggressively, including

their manufacturing [5]–[7], modeling [8], [9], and electrical

characterization [10].

However, conventional TSVs are susceptible to coupling

noise and crosstalk, moreover, the lossy silicon substrate

(∼10 · cm) between the signal and ground TSVs as well

as the impedance mismatch results in significant loss and

Manuscript received August 23, 2016; revised October 3, 2016;

accepted October 11, 2016. Date of publication October 27, 2016; date

of current version November 22, 2016. This work was supported in

part by the National Natural Science Foundation of China under Grant

61301006 and Grant 61574016 and in part by 111 Project of China under

Grant B14010. The review of this paper was arranged by Editor M. S. Bakir.

(Corresponding author: Yingtao Ding)

The authors are with the Beijing Institute of Technology, Beijing 100081,

China (e-mail: czm@bit.edu.cn; ytd@bit.edu.cn).

Color versions of one or more of the figures in this paper are available

online at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/TED.2016.2618383

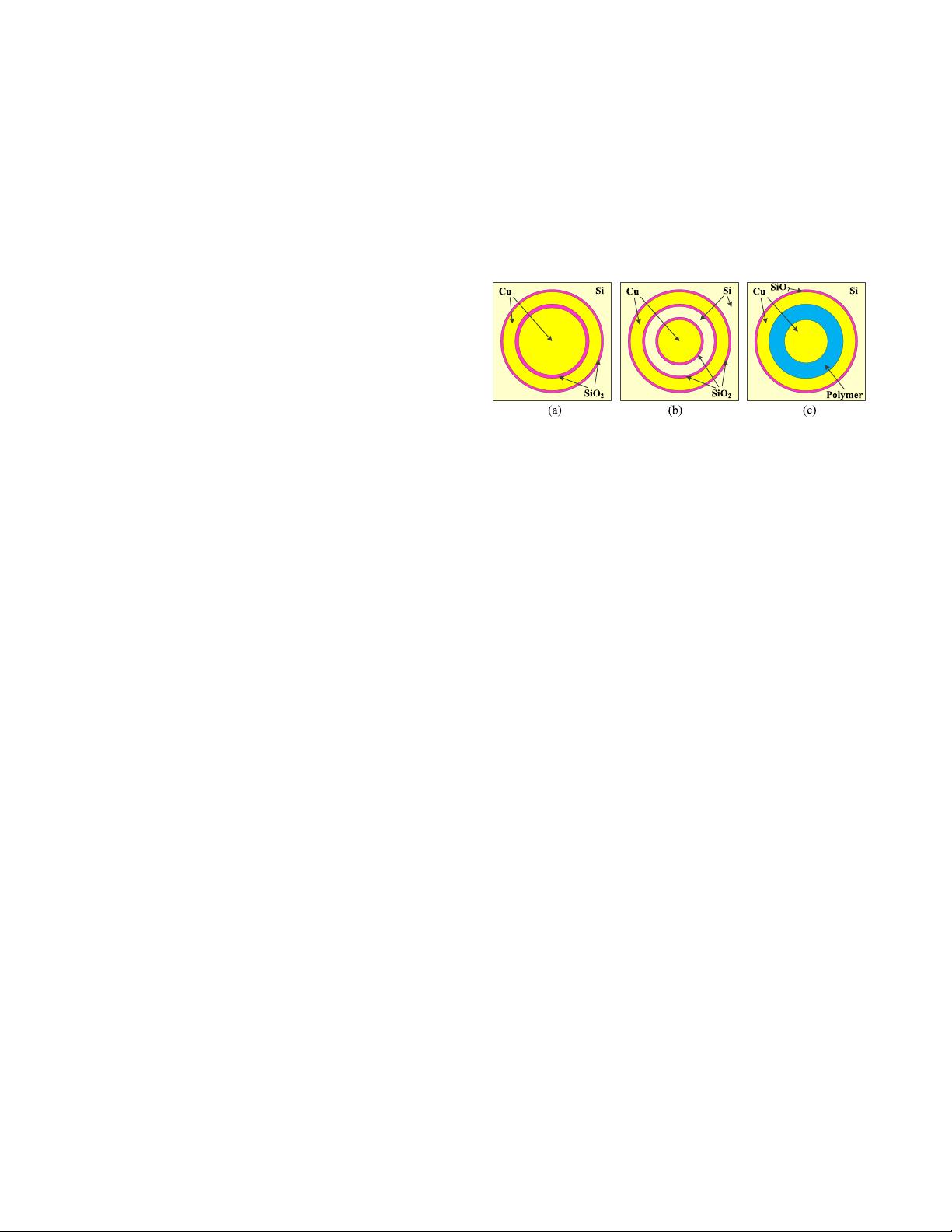

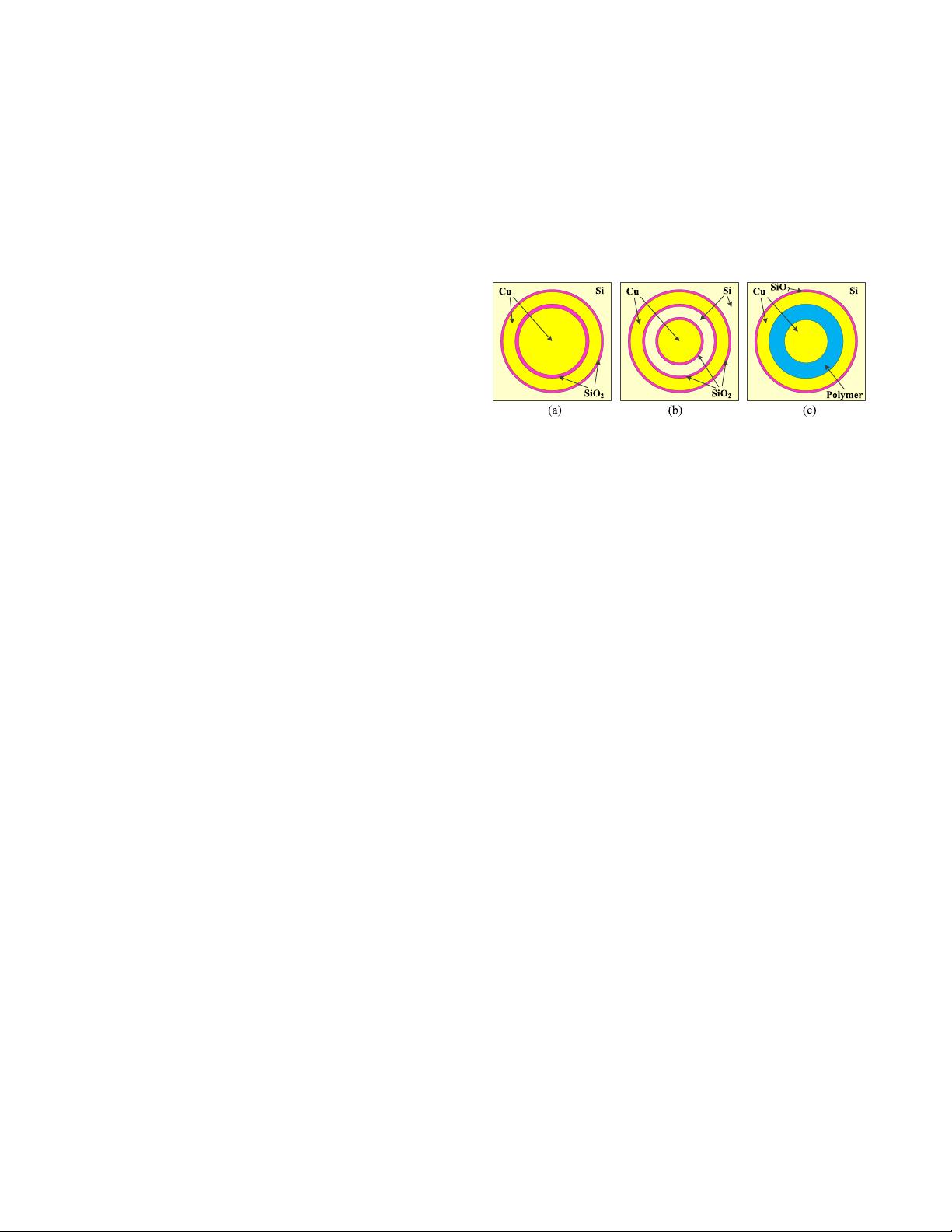

Fig. 1. Cross-sectional views of three coaxial TSV configurations using

Cu as the inner and outer conductors. (a) SiO

2

dielectric. (b) SiO

2

/Si mixed

dielectric. (c) Polymer dielectric.

poor signal integrity, especially at high frequencies [11], [12].

In order to overcome these drawbacks, coaxial TSVs with self-

shielding property have been proposed in [13]–[16], which

provide high immunity to noise and interference, avoid signal

reflection due to impedance mismatch, and reduce insertion

loss in radio frequency and millimeter-wave (MMW) signal

transmission or high-speed data communication.

Fig. 1 shows three main coaxial TSV configurations, which

all employ Cu as the conductive material but use different

kinds of dielectrics. Fig. 1(a) shows coaxial TSVs utilizing

SiO

2

as liner material [17], [18]. Since the SiO

2

liner thickness

is usually several hundred nanometers limited by chemical

vapor deposition, the achievable radius ratio n (outer shell

to inner conductor) is very close to unity, which leads to

small characteristic impedance and poor impedance matching.

The coaxial TSV configuration shown in Fig. 1(b) employs a

mixed SiO

2

/Si liner between the inner and outer conductors,

which helps to increase the ratio n for better impedance

matching [19]–[21], however, the transmission loss perfor-

mance of this kind of coaxial TSV is compromised due to

the insertion of a lossy silicon layer. In order to achieve low

transmission loss and well-controlled characteristic impedance

simultaneously, the structure using polymer liner is proposed

and successfully fabricated [12], [13], as shown in Fig. 1(c).

However, their overall TSV dimensions are on the order of

hundred micrometers, which are not suitable for high-density

3-D integration. Besides, since the previous works on coaxial

TSVs all utilize metal (e.g., copper) as the conductive material,

they involve a series of complicated fabrication processes to

form inner and outer conductors and dielectric layers.

In this paper, a coaxial TSV based on heavily doped silicon–

insulator–silicon (SIS) structure is proposed, fabricated, and

characterized, which employs the ultralow-resistivity sili-

con (ULRS) as the material for inner and outer conductors

0018-9383 © 2016 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission.

See http://www.ieee.org/publications_standards/publications/rights/index.html for more information.