www.vtiinstruments.com

EX10xxA Introduction 17

The EX10xxA is as easy-to-use as it is powerful. An integrated web page provides a convenient

way to instantly verify communications and instrument functionality, while industry standard VXI

plug & play and IVI drivers provide a familiar application programming interface to reduce

integration and program development time.

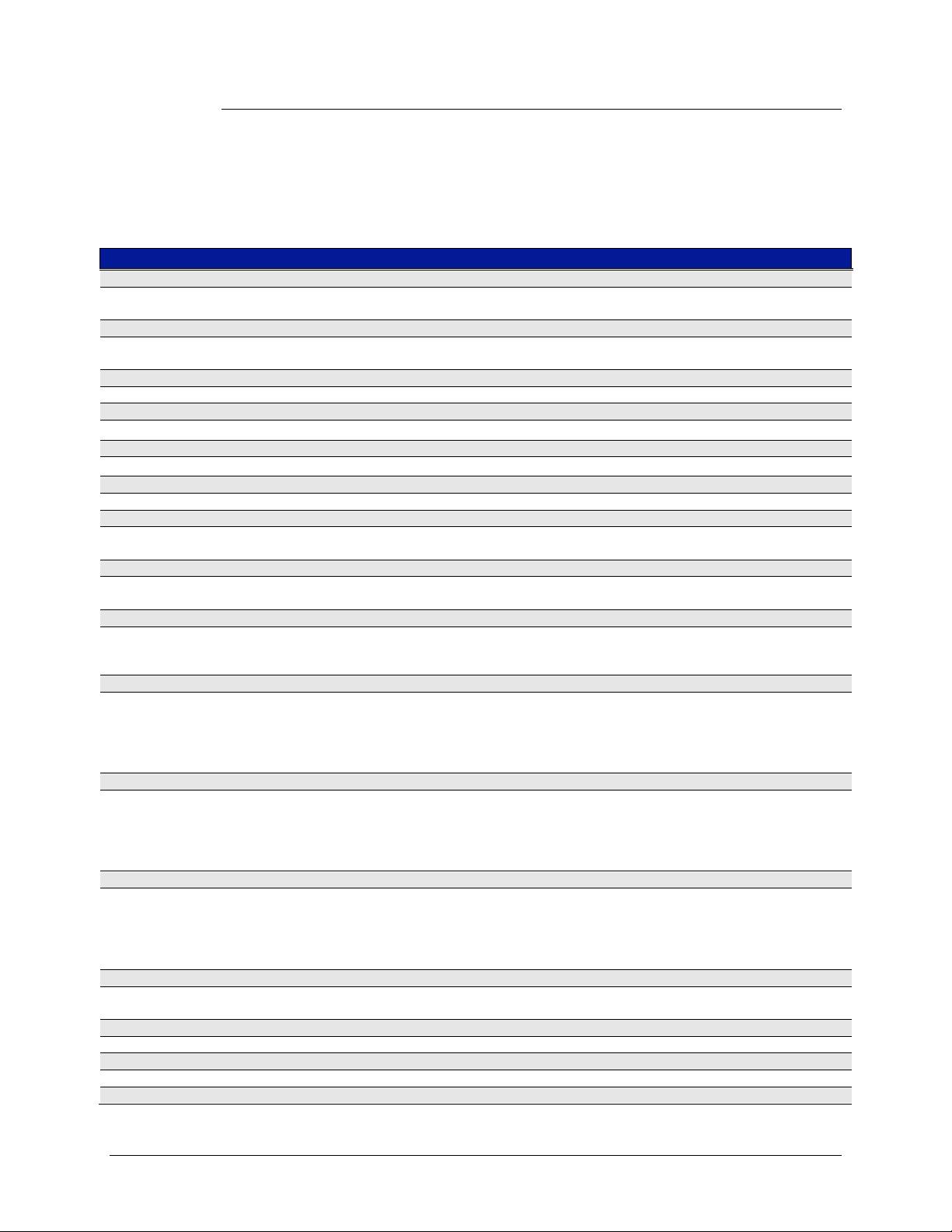

FEATURES

Combined Thermocouple and Analog Inputs

Easily combine thermocouple and analog signals on these versatile instruments with sampling

rates up to 1 kSa/s (kilosamples per second) per channel. Each input incorporates an independent

signal conditioning path with software selectable filters for maximum flexibility. Complete

channel independence ensures data integrity regardless of sample speed or input overload

conditions.

End-to-end Self-calibration

Complete end-to-end self-calibration is provided for each signal path on a programmable basis. A

highly accurate calibration source provides reference signals that are applied prior to analog

filtering and gain circuits to compensate for drift, aging, or temperature variations. Self-calibration

is simple and quick, and can be performed as often as desired.

Scalable for Synchronized High-Speed, High-Channel Count

With LXI™ Class A compliant features like a built-in Trigger Bus™ hardware trigger subsystem,

the EX10xxA supports easy integration and synchronization of multiple devices, including

existing VXIbus instrumentation.

Note: LXI Class A compliance for RX1032 is in progress.

Open Thermocouple Detection (OTD)

While the integration of the EX10xxA removes many of the reliability and connectivity problems

typically faced by system designers, they still must contend with the reliability of the sensor

connections. Fortunately, the EX10xxA aids a great deal in that regard as well. Each thermocouple

input channel generates a very small current (±7.5 nA/channel) which drives the input to an open-

circuit state if the transducer is disconnected. Implemented in this way, open transducer detection

is continuous and requires no discrete function call on the part of the user to be activated, offering

more protection than systems that only check on command, as a broken sensor can occur at any

time during testing, not just at installation. In a typical application, the OTD has no effect on the

measurement. However, many thermocouple simulators have a much higher impedance than a

thermocouple so an offset may be introduced into the reading when using a simulator. In general,

the OTD should only be active on channels that are being used with actual thermocouples.

The EX10xxA additionally offers a front panel OTD LED for each channel that illuminates upon

the recognition of a fault condition. This provides for quick and easy problem channel

identification. Moreover, to ensure that even intermittent problems are identified, the fault

recognition is a latching mechanism, retaining the information of the current acquisition sequence

until a new acquisition is initiated. Note that voltage channels do not include internal CJC

thermistors, but that each voltage D-sub includes connections for the connection of user-supplied

thermistors.

Cold Junction Compensation (CJC)

For highest accuracy and stability, the EX1000A-TC, EX1016A, EX1032A, EX1048A and

RX1032 provide embedded isothermal input sections that are monitored by twelve precision

thermistors (based on Model#, the number of thermistors can vary), one for every four

thermocouple channels. (Note, the EX1000A may utilize external thermistors as described in the

Voltage Connections section). To ensure that the CJC information is current and time correlated