"香皂盒塑料注塑模具设计及分析:PRO/E软件应用与工程图绘制"

版权申诉

70 浏览量

更新于2024-02-28

收藏 388KB DOCX 举报

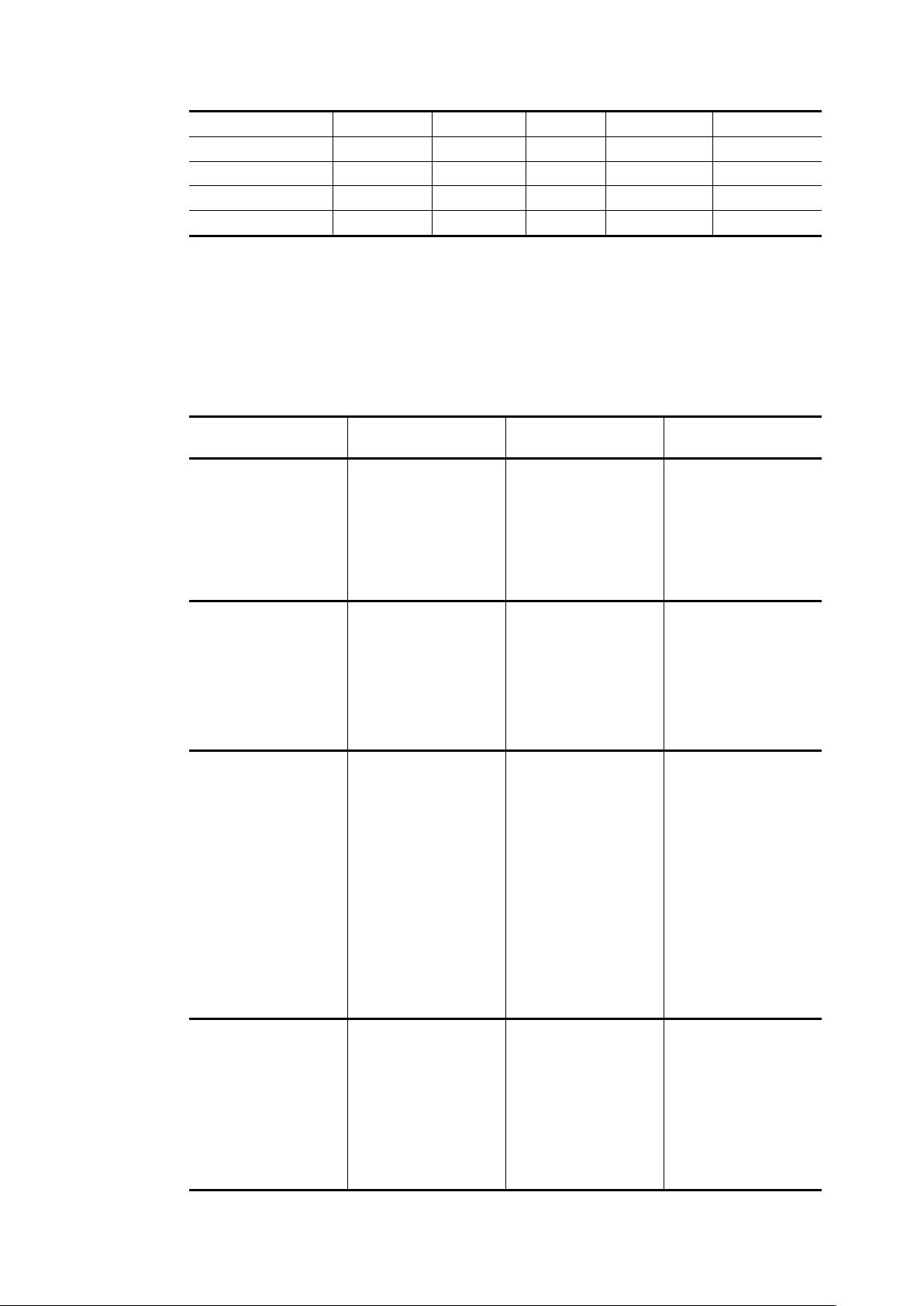

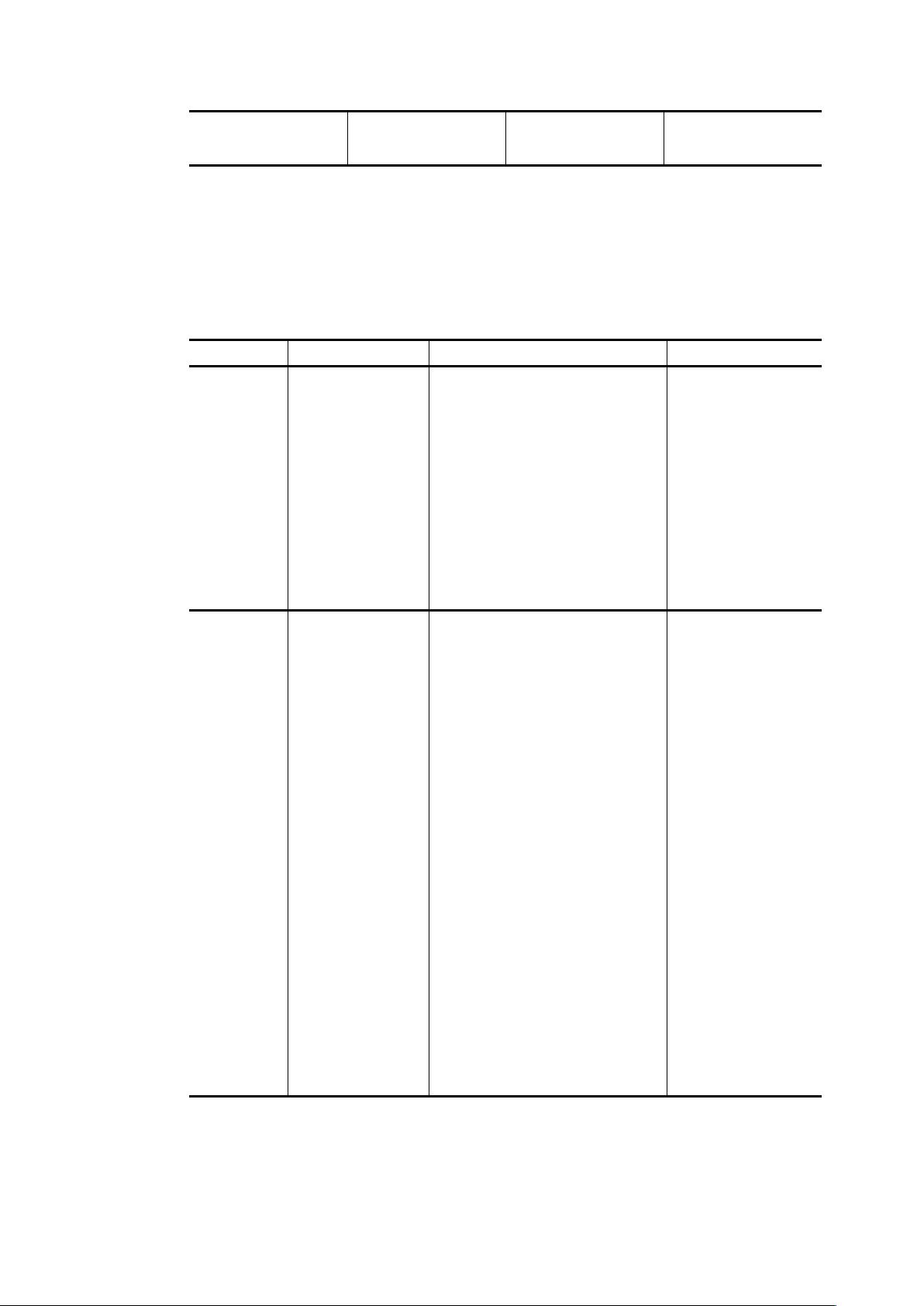

The plastic soap box injection mold design is an important aspect in the production of daily use products. This design aims to create a mold for plastic soap boxes, with a focus on the overall structure, component design, and calculations. The use of software such as PRO/ENGINEER has been instrumental in the analysis and rationalization of the mold structure, leading to a shorter design cycle and the creation of the required mold.

The design of the mold followed a specific route, starting with the overall structural design, followed by the 3D design of the mold cavity and core, and then the 2D drawing of the mold components. Utilizing Pro/ENGINEER software, the creation of 3D models and 2D engineering drawings for the parts was based on physical measurements. The various parts such as the split surface and mold cavity were drawn and evaluated for their rationality. Additionally, the software was used to select the injection machine, which helped in avoiding complex calculations.

Once the individual parts were created as solids, the assembly module was used to simulate the assembly of the various parts and generate the mold product drawing. The process involved a comprehensive and detailed approach, ensuring that all aspects of the mold design were thoroughly considered and analyzed.

The key focus of the design included considerations for the soap box, injection mold, PRO/E, CAD, and the use of software for efficient and effective design processes.

In summary, the process of designing a plastic soap box injection mold involved careful planning, structural design, component creation, rational analysis, and software utilization. The result is a well-designed mold that meets the required specifications and standards. The utilization of modern software and technologies has contributed to streamlining the design process and ensuring the creation of an effective and efficient mold for the production of plastic soap boxes.

598 浏览量

199 浏览量

点击了解资源详情

2023-09-13 上传

2023-09-13 上传

2023-09-13 上传

南抖北快东卫

- 粉丝: 84

- 资源: 5587