3.1.2 Additional Features

Several features have been included to increase the overall stability of the winder and to increase control and monitoring of the winding process.

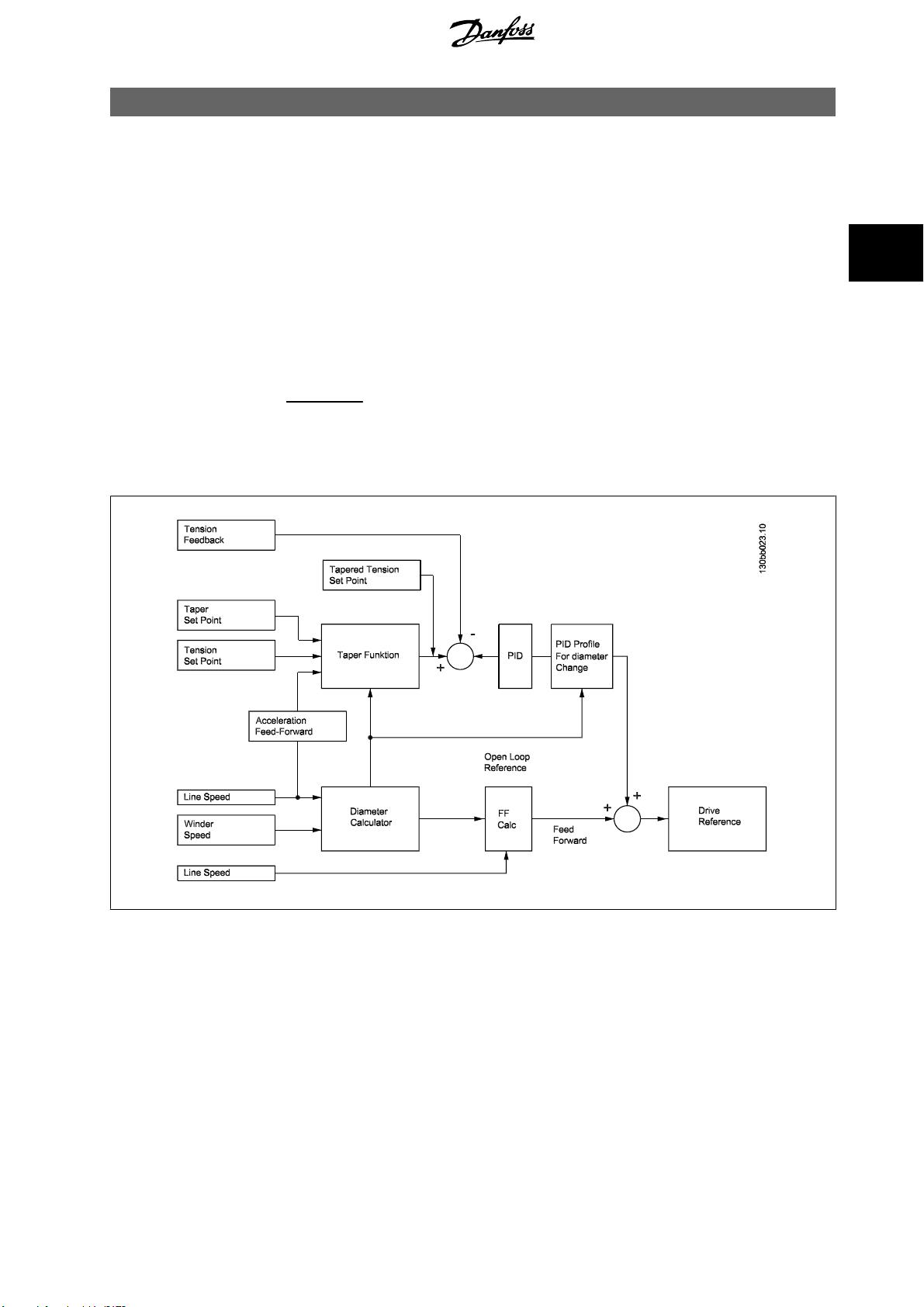

• Acceleration Feed-Forward: The Winder block diagram includes an acceleration feed-forward function that allows a shift in the tension/taper set

point based on changes in line speed. This provides a tension boost during initial acceleration to help compensate for system inertia.

• Tension-Taper Set-Point Ramp: The tapered tension set point generator will integrate any changes to the tension or taper set points over multiple

program scans. A parameter is provided to increase or decrease response time.

• Diameter Calculator Limiter: The diameter calculator includes a similar integration technique. A maximum rate of diameter change can be

adjusted by parameter. In addition, the calculated diameter is restricted from moving in the wrong direction to only 20 % of the rate applied to

the expected change in diameter. For example, if the station is rewinding a roll, the diameter is not expected to reduce in diameter.

• Diameter Calculator Minimum Speed: There is also a minimum speed requirement to enable the diameter calculator. At low speeds, the line and

winder speeds may not have enough resolution to accurately calculate diameter. A parameter is provided to define a minimum line speed required

for the diameter calculator to function. Until that speed is reached, the diameter value will not change.

• Programmable Analog Inputs: The VLT AutomationDrive has two analog inputs. Inputs 53 and 54 are analog inputs with a voltage range of ±10

VDC or a current range of 0/4-20mA. Use DIP-switch S201/S202 to select configuration. The source of the tension and taper set-points can be

adjusted by either analog input or parameter setting. The tension feedback and initial diameter measurement can only use analog inputs.

Parameters are provided to select the source of each input. Care must be taken not to program a single input for more than one function.

• Initial Diameter Measurement: In many winding applications there are very few variations in starting core diameter or initial roll size. A choice

of three programmable starting diameters can be programmed and logically selected. For applications where the starting diameter can vary

regularly, the Winder will allow the initial diameter to be measured through an analog input signal. Scaling parameters are provided to set the

analog level at core and at full roll. This function assumes a linear change in the diameter measurement signal.

• End of Roll Detection: An output is provided to indicate a diameter limit. For rewinding applications, the diameter limit occurs when the calculated

diameter exceeds a set limit. For unwinding applications, the diameter limit occurs when the calculated diameter is less than the set limit. The

station will continue to run after a diameter limit is detected. This output can be used to stop the line for a roll change.

• Tension Limit Detector: The Winder includes a tension limit detection (TLD) feature. This feature allows the Winder to trip if a low-tension or

high-tension feedback exists for a period of time. The trip delay includes a normal running delay as well as a secondary starting delay.

3 Introduction to Center Winder Controller VLT

®

Center Winder MCO 352

8

MG.33.T1.02 - VLT

®

is a registered Danfoss trademark

3