Defect detection and recognition based on ADABOOT-

SVM integrated model

ZhiKai Liang

Beijing Institute of Graphic

Communication

Beijing No. two, Xinghua street, China

13051379003, 102600

Liangzhikai0812@gmail.com

ShaoZhong Cao

Beijing Institute of Graphic

Communication

Beijing No. two, Xinghua street, China

13520127931, 102600

chaoshaozhong@gmail.com

YuKun Tan

Beijing Institute of Graphic

Communication

Beijing No. two, Xinghua street, China

18801017073, 102600

tanyukun@gmail.com

ABSTRACT

As the core component of printing machinery, the surface finish

and geometric accuracy of printing drum will have an important

impact on the quality of printed matter. However, the use of acid

ink, alcohol and other chemical raw materials corrode the drum,

leading to local collapse or spots. How to effectively identify the

types of drum defects has become an important issue. To solve

this problem, a defect detection and recognition framework based

on adaboot-SVM ensemble learning model is proposed. The

framework is composed of two parts: feature extraction and

classifier design. The first part is feature extraction from

directional gradient histogram (HOG). In the second part, we

construct an ensemble of different SVM classifiers to identify

defects. The validity of the proposed model is verified by nine

different defects. The results show that the integrated model of

adaboot SVM is helpful to improve the recognition accuracy of

defects.

Keywords

Defect recognition; ensemble learning; multiple classifier sets;

SVM

1. INTRODUCTION

As an important branch of machine vision technology, visual

inspection is a hot research direction in the field of product

nondestructive testing in China. Data shows that the domestic

market in 2015 has reached 350 million US dollars, accounting

for 8.3% of the global market, growth rate is 22.2%, ranking first

in the world, China has become the world's third largest machine

vision market after the United States and Japan. From 2016 to

2020, the growth rate of China's machine vision market is

expected to remain above 20%, and will reach a billion dollar

market space. Visual sensor has many advantages, such as large

amount of information, non-contact with workpiece, high

sensitivity and accuracy, strong anti-electromagnetic interference

ability, and so on. It is a hot research field. As the core component

of printing machinery, the surface finish and geometric accuracy

of printing drum will have an important impact on the quality of

printed matter. However, the use of acid ink, alcohol and other

chemical raw materials corrode the drum, leading to local collapse

or spots. How to effectively identify the types of drum defects has

become an important issue.

Scholars at home and abroad have studied and proposed a variety

of new feature extraction algorithms from the analysis of feature

extraction, machine learning, depth learning and other methods,

and achieved good recognition results. However, there are many

kinds of defects, and some defects are very similar. The selection

of effective feature combination usually depends on the

experience of experts. The accuracy of recognition is difficult to

guarantee. Therefore, it is of great significance to find a data-

based self-learning method to improve the performance of defect

recognition. With the rapid development of artificial intelligence

technology in recent years machine learning and its application

had a hot topic in the field of artificial intelligence. At present,

machine learning has achieved good results in some pattern

recognition fields [15-19], such as speech recognition, image

classification, natural language processing and so on. At the same

time, scholars at home and abroad are committed to introducing

machine learning into defect recognition [20-24]. Therefore, this

paper uses the gradient histogram of Oriented Gradient proposed

in reference [25] to extract the features of defects. At the same

time, considering that the idea of ensemble learning can be used to

construct an effective combined classifier model, it can be used to

replace the soft Max classifier used in most depth learning

applications. Based on this, this paper proposes a defect

identification method combining HOG and ensemble learning.

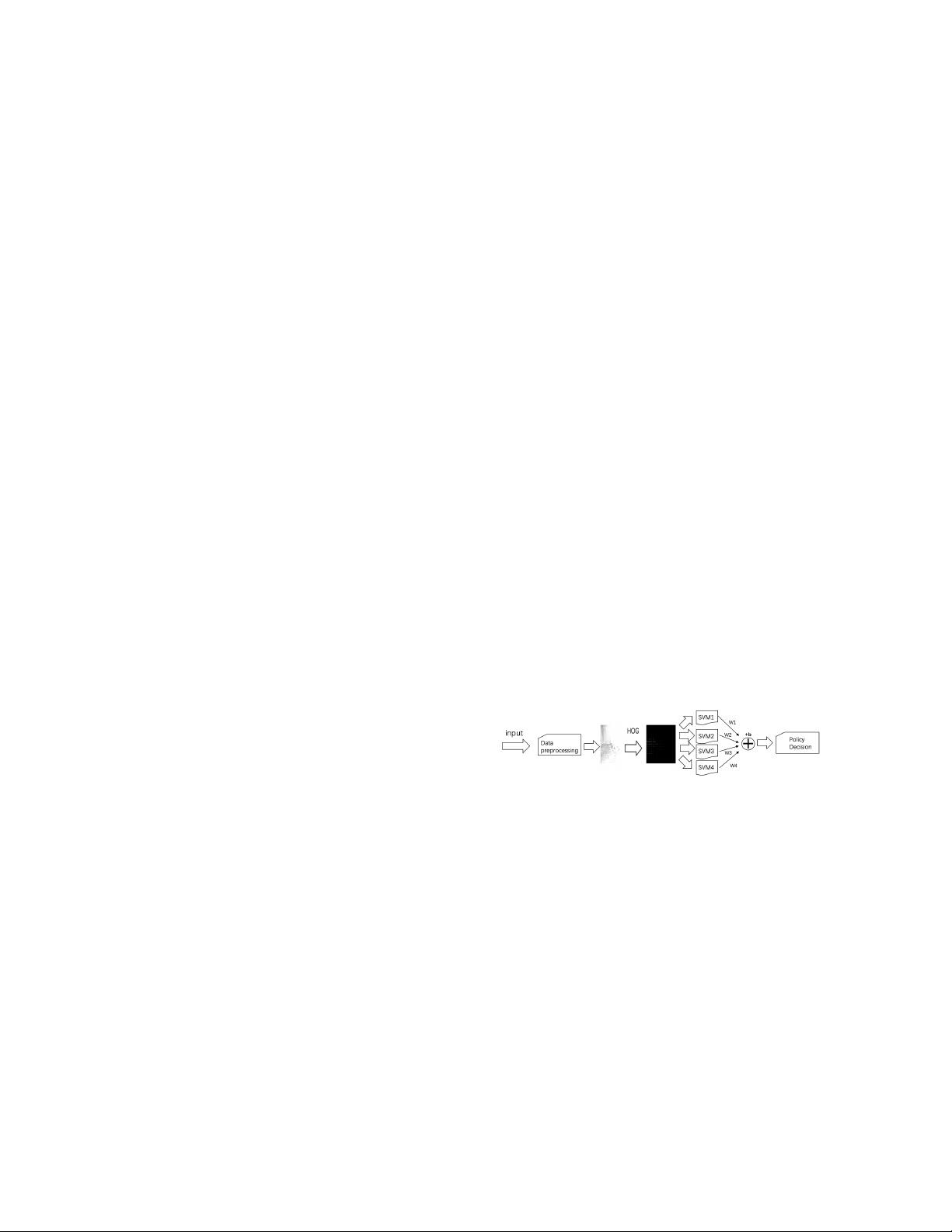

The specific process of the model is shown in Figure 1. First,

noise reduction is done in the preprocessing stage. Then, we

create the defect features extracted from HOG images. Finally, in

the classifier design stage, a multi-SVM linear combination

classifier (MSVMLC) is constructed for classification and

recognition.

2. Histogram of OrientedGradients

Directional gradient histogram (HOG) is an image descriptor for

object detection which is widely used in computer vision and

image processing. This method uses the histogram of gradient

orientation (HOG) feature to express the detected object, extracts

the shape information of the detected object, and forms a rich

feature set.

Compared with other descriptors, HOG descriptors have some key

advantages. Because it runs on a local element, it is invariant to

geometric and photometric transformations except for better

capturing local shape information, which only occurs in larger

spatial regions. Moreover, the HOG is obtained in a densely

sampled image block, and the spatial position relationship