AN696

DS00696A-page 10 Preliminary 2000 Microchip Technology Inc.

Stand-alone Operation

The provided application firmware allows the servo-

motor to perform a few basic motions without a PC con-

nected. Specifically, data for three different motion

profiles are stored in the MCU program memory and

are loaded into data memory at start-up. Each profile is

selected by turning on DIP switch #2, #3, or #4, con-

nected to PORTB and pressing the MCLR

button.

The software polls the DIP switches once, at start-up,

to see if a profile should be executed. The selected pro-

file will begin to execute immediately. If DIP switch #1

is turned on in combination with one of the other

switches, the selected profile will execute repeatedly.

PICmicro MCU RESOURCES

There is a broad range of PICmicro devices that can be

used to implement the servomotor application, depend-

ing on the level of performance that you need. To begin

with, let’s consider the processing time needed by the

servo calculations.

A large amount of time is spent in the servo calcula-

tions executing the compensator, which requires one or

more multiplications depending on the type of algorithm

used. Three 16 x 16 signed multiplications are required

by the PID compensator algorithm used here. Since the

servo update calculations must be performed fre-

quently, a hardware multiplier can provide a significant

reduction in the MCU bandwidth. With a 8 x 8 hardware

multiplier, each 16 x 16 multiplication can be performed

in approximately 32 instruction cycles. Without the

hardware multiplier, each multiplication can take 500

instruction cycles or more, depending on the algorithm

that is used.

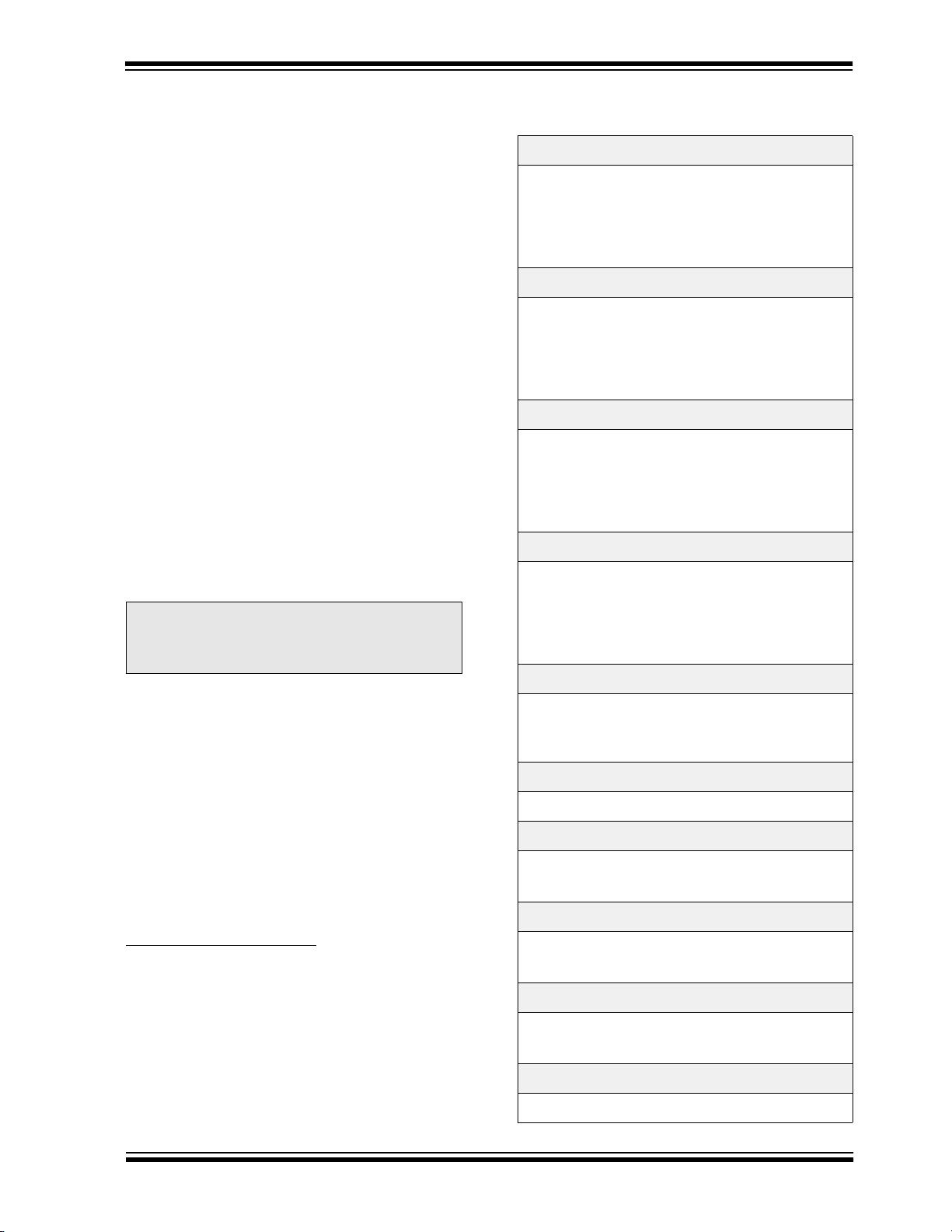

The servo calculation times were compared for the

PIC16CXXX and PIC18CXXX architectures, using the

same source code. Table 2 shows the performance

results. You can easily see the increase in available

bandwidth gained by the hardware multiplier. For a

given servo update period, the hardware multiplier in

the PIC18CXXX architecture frees a large amount of

MCU bandwidth for performing other tasks. In addition,

extra MCU bandwidth may be obtained from the

PIC18CXXX architecture, since the devices may be

operated up to 40 MHz.

Table 3 and Table 4 show a comparison of memory

usage by the servomotor application, for both the

16F877 and the 18C452. Depending on the memory

requirements for motion profile segment data and other

application functions, the design may be adapted for

other MCUs. As an example of a minimal implementa-

tion, this application could be modified to operate on a

PIC16C73B. The PIC16C73B has 22 I/O pins, 4K x 14

words of program memory, and 192 bytes of data

memory.

The resolution of the available timer resources must be

considered when using the position sensing method

described here. The maximum RPM of the servomotor

is a function of the timer resolution, servo update fre-

quency, and the resolution of the incremental encoder.

Because two’s complement arithmetic is used to find

the motor position, the timers used to accumulate the

encoder pulses should not increment more than 2

N-1

counts during each servo update interval, or position

information will be lost.

When a PIC16CXXX device is used for the servomotor

application, Timer0 and Timer1 are the only timers with

an external clock input and Timer0 has only 8 bits of

resolution. For some cases, this may limit the maxi-

mum motor RPM. A formula that can be used to calcu-

late the maximum RPM is given in Equation 1 below:

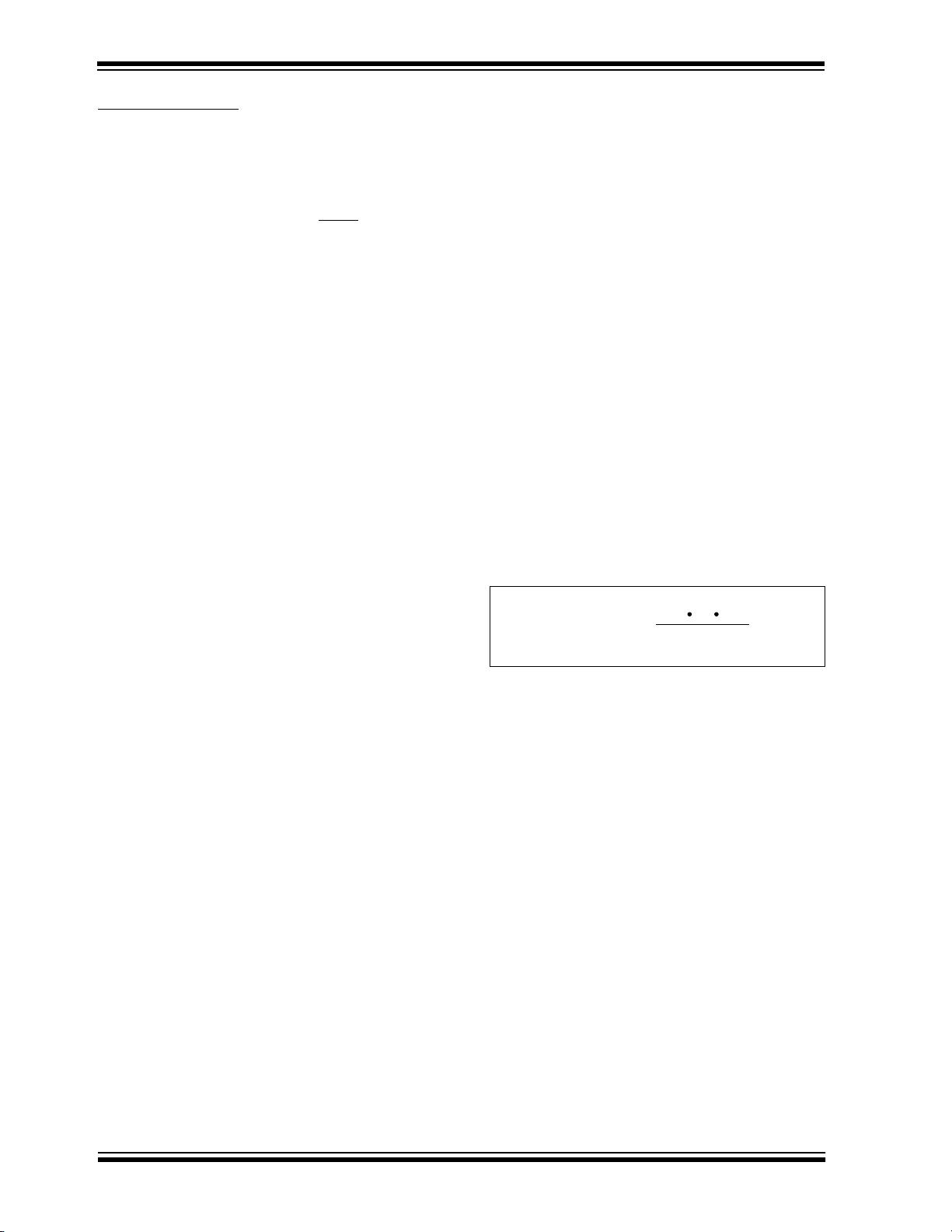

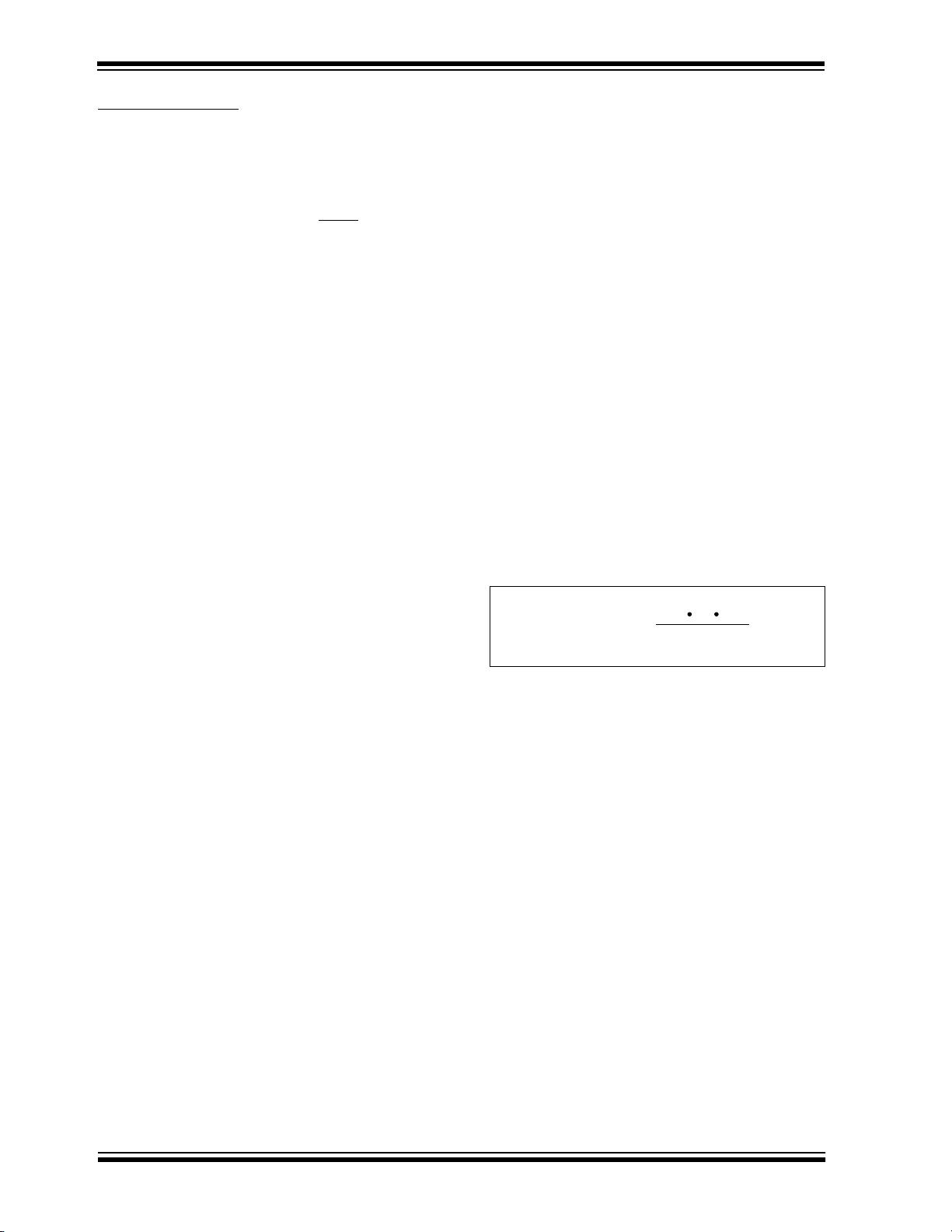

EQUATION 1: MAXIMUM RPM

In this equation, N represents the resolution of the timer

in bits, f

S

, is the servo update frequency, and CPR is

the resolution of the encoder. The incremental encoder

used in this application provides 500 CPR. For the

moment, let’s assume that our servo update frequency

is 1000 Hz. Using 1x decoding, the maximum RPM that

we can permit without a timer overflow, is over 15,000

RPM. This maximum limit is of no concern for us, since

the motor we are using provides a no-load speed of

6000 RPM. Now, let’s assume that a 4x decoding

method was used, so that our encoder now provides

2000 CPR. Now, the maximum motor speed is 3840

RPM, which is definitely a problem! In this case, the

servo update frequency would have to be increased, if

possible, or the encoder resolution decreased.

RPM

MAX

=

2

N-1

f

s

60

CPR