手机彩屏背光:WLED驱动器的选择与演进

130 浏览量

更新于2024-08-28

收藏 328KB PDF 举报

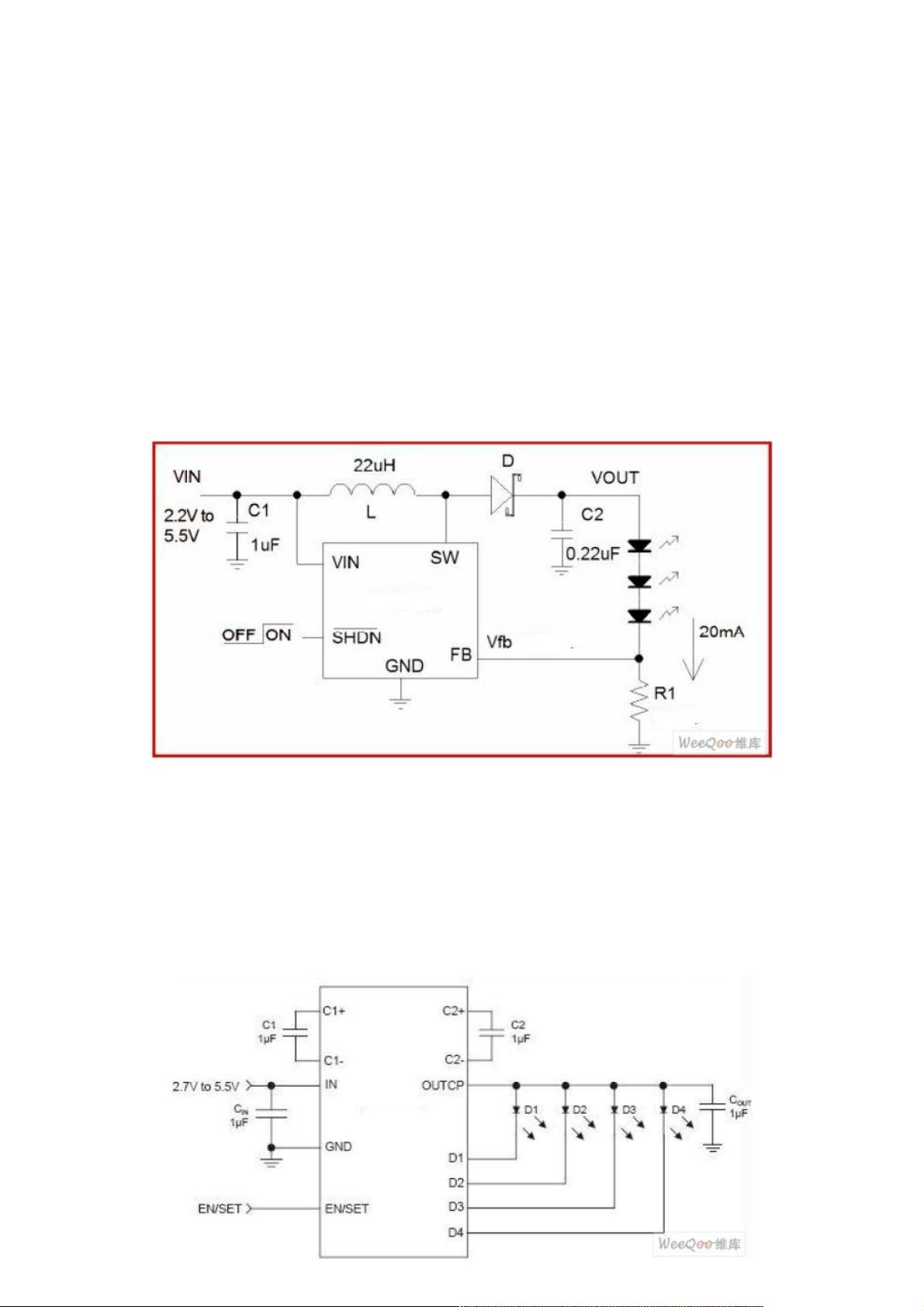

"本文探讨了如何在成本与性能之间找到平衡,选择适合的WLED(白光LED)驱动器。WLED驱动器的主要任务是提供稳定的电流,确保LED亮度一致,不受电池电压波动影响。文章介绍了三种不同类型的WLED驱动器架构:电感升压型、分数电荷泵型和低压降恒流型,并分析了它们的特点和适用场景。电感升压型驱动器虽然简单,但可能产生电磁干扰影响手机性能。分数电荷泵型能有效降低电磁问题,而低压降恒流型则在2008年后逐渐成为主流,因其能提供更高效、低噪声的解决方案。"

在选择低成本高性能的WLED驱动器时,首先要考虑驱动器的基本功能。WLED驱动器必须能够稳定提供电流,以确保LED亮度一致,同时减少电池电压变化带来的影响。早期的电感升压型驱动器,通过电感提升电压,实现电流恒定,然而这种方式可能导致电磁辐射和干扰,影响手机的射频性能。因此,对于对电磁兼容性要求较高的应用,如高端智能手机,这种设计可能并不理想。

接着,分数电荷泵型WLED驱动器应运而生。这种驱动器利用电荷泵技术,可以更高效地调整电压,且产生的电磁干扰相对较小。分数电荷泵驱动器通常具有多模式,可根据LED的VF值和电源电压自动调整,以适应不同工况,提高了系统的适应性和效率。

最后,低压降恒流型WLED驱动器在2007年后逐渐受到青睐。这类驱动器能够在较低的电压差下维持恒定电流,减少了功率损失,降低了热耗,从而提高了整体系统效率,同时还能保持低噪声水平,有利于维持手机内部的电磁环境稳定。

在选择WLED驱动器时,需要综合考虑以下因素:

1. **效率**:高效率驱动器能更好地利用电池能量,延长手机的使用时间。

2. **稳定性**:驱动器应能稳定提供电流,确保LED亮度一致。

3. **电磁兼容性(EMC)**:驱动器应尽可能减少电磁干扰,不影响其他电子元件的正常工作。

4. **成本**:在满足性能需求的同时,寻求成本效益最高的解决方案。

5. **封装尺寸**:对于空间有限的移动设备,驱动器的体积和封装也是一项重要因素。

在评估以上因素后,根据具体应用的需求,可以选择最合适的WLED驱动器架构。例如,对于对电池寿命有较高要求的设备,低压降恒流型驱动器可能是最佳选择。而在对电磁兼容性要求严格的环境中,分数电荷泵型驱动器则更为合适。因此,了解每种驱动器架构的优缺点,结合产品定位和技术要求,是选择低成本高性能WLED驱动器的关键。

2020-11-08 上传

2021-08-29 上传

2023-07-27 上传

2023-02-26 上传

2024-09-15 上传

2023-06-06 上传

2023-06-07 上传

2023-06-07 上传

2023-09-05 上传

weixin_38530846

- 粉丝: 5

- 资源: 930

最新资源

- 李兴华Java基础教程:从入门到精通

- U盘与硬盘启动安装教程:从菜鸟到专家

- C++面试宝典:动态内存管理与继承解析

- C++ STL源码深度解析:专家级剖析与关键技术

- C/C++调用DOS命令实战指南

- 神经网络补偿的多传感器航迹融合技术

- GIS中的大地坐标系与椭球体解析

- 海思Hi3515 H.264编解码处理器用户手册

- Oracle基础练习题与解答

- 谷歌地球3D建筑筛选新流程详解

- CFO与CIO携手:数据管理与企业增值的战略

- Eclipse IDE基础教程:从入门到精通

- Shell脚本专家宝典:全面学习与资源指南

- Tomcat安装指南:附带JDK配置步骤

- NA3003A电子水准仪数据格式解析与转换研究

- 自动化专业英语词汇精华:必备术语集锦