Ph: 412-963-7470 • Email: sales@aerotech.com • www.aerotech.com

WORLD HEADQUARTERS: USA

THE AMERICAS • EUROPE & MIDDLE EAST • ASIA-PACIFIC

Dedicated to the

Science of Motion

AH1215A-LPM

Precision Additive Manufacturing

3D Motion Control Subsystem and Component Solutions

Control Systems

• Advanced control capabilities for

coordinated motion

• Innovative features for minimizing

dynamic tracking errors

• Velocity profiling maintains a constant

vector velocity over complex profiles for

total material distributing control

• Powerful, user-friendly controllers

and drives to enhance your complete

process

Mechanical Systems

• 3D motion down to nanometer-level

performance

• Full line of linear and rotary stages

in both mechanical-bearing and air-

bearing versions

• Component-level solutions for cost

effective, reliable motion

• Integrated subsystems and turnkey

machines customized to exact

specifications

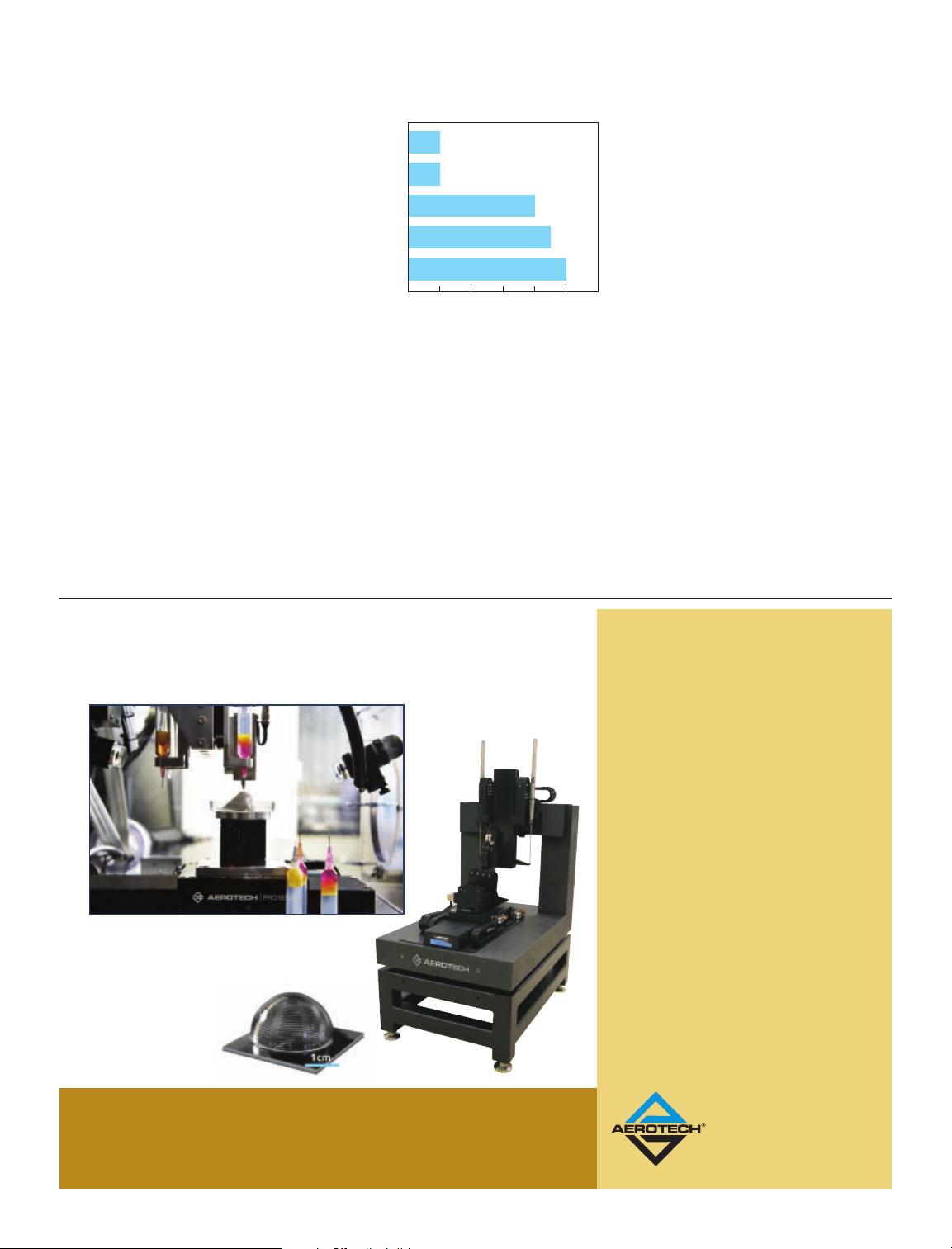

Subsystems with six

degrees of freedom

Aerotech motion products are currently

used in a variety of additive manufacturing

applications.

A 3D printed structure

produced using an

Aerotech motion system.

Photo provided by

Professor Jennifer A. Lewis,

Harvard University

*Required much slower scan speed...overheating

6543210

Efciency (ft

2

*mils/ kW*min.)

Laser paint stripping efciencies

Q-switch ber laser on white

CW ber laser on white*

CO

2

laser on white

CO

2

laser on gray

Fiber laser on gray

6 Industrial Laser Solutions SEPTEMBER/OCTOBER 2016 www.industrial-lasers.com

application report

sweeping a continuous

laser beam across the

painted surface. In either

case, the top layer of

paint is heated and then

vaporizes, followed by

immediate combustion

as it leaves the surface

and encounters oxy-

gen in the air. The heat

of combustion in laser

paint stripping can be

many times higher than

the laser energy depos-

ited to the surface, and

efficient removal of

this heated effluent is

essential for process efficiency and work-

place safety.

All paints do not absorb laser energy

the same way, and all laser wavelengths

are not absorbed the same way by

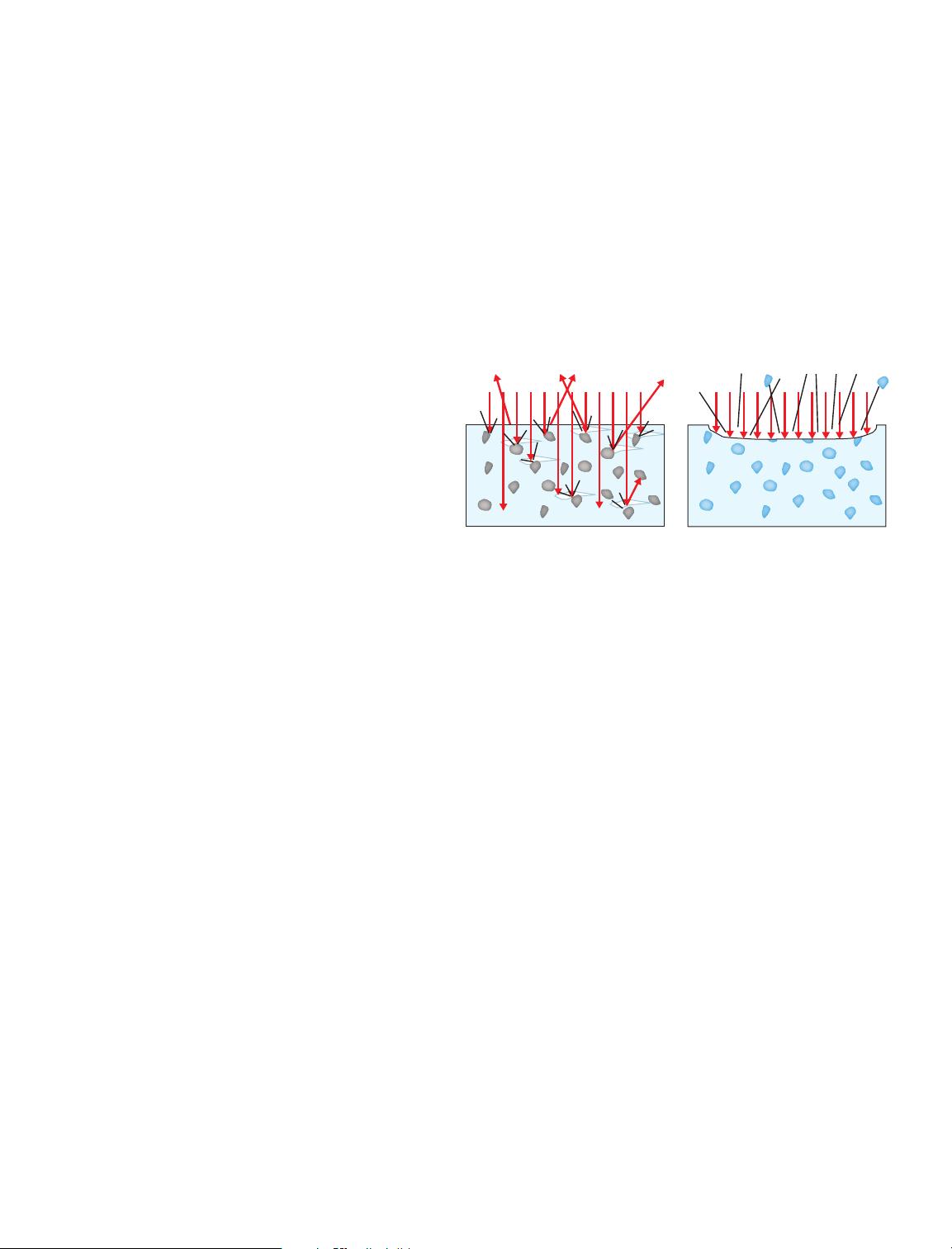

paints. FIGURE 1 shows the two means

by which laser energy (1µm from sol-

id-state lasers vs. 10.6µm from CO

2

lasers) is absorbed by paints. If the paint

is comprised of transparent resin with a

dark pigment, like typical military gray

paint, then a 1µm beam can be deliv-

ered into the depth of the painted sur-

face and absorbed along the way by the

dark pigment. This process can be very

efficient. However, if the paint is white,

the pigment is highly scattering to the

1µm beam, and the process is essentially

prevented from operating. On the other

hand, a CO

2

laser beam can successfully

remove any color of paint since the laser

energy is absorbed at the outermost sur-

face and does not transmit through the

thickness. This ability of CO

2

laser paint

stripping becomes additionally important

if removal of primer is required—a func-

tion that is quite difficult for the shorter

wavelength to accomplish.

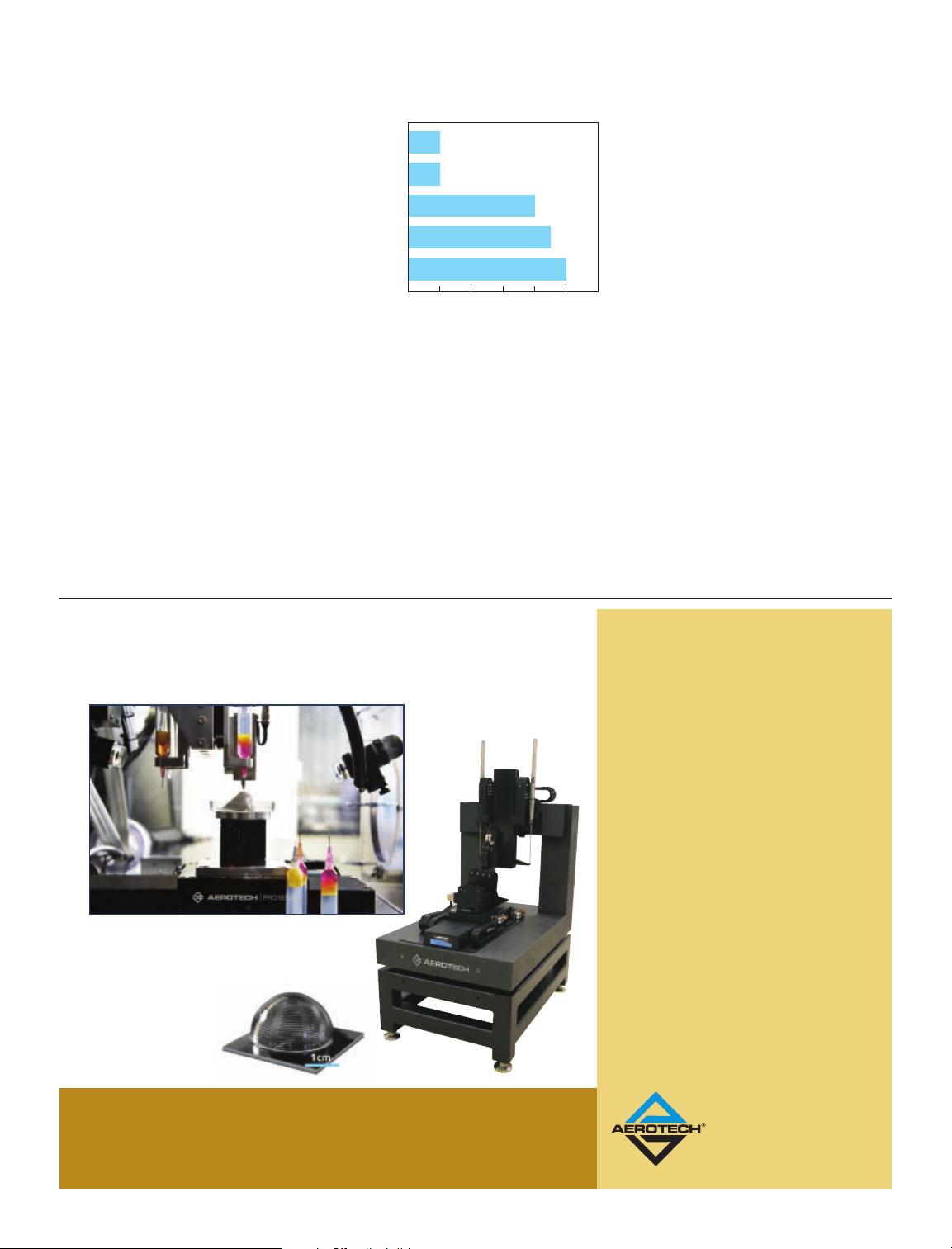

The efficiency of laser paint stripping

performance is measured as Volume

of Paint Removed/Energy Delivered for

Removal, and the specific units (as initiated

by the Air Force many decades ago) are:

Ft

2*

mils / kW

*

min (where mils are thou-

sandths of an inch)

This metric (along with actual laser

power) is extremely important in under-

standing productivity, thermal loading

on the aircraft, and overall process cost.

Values for this metric on different paints

with different lasers are shown in FIGURE 2.

FIGURE 2. Paint stripping efficiencies with different lasers

and different paints.

1609ils_6 6 9/2/16 2:07 PM