COL 10(1), 013104(2012) CHINESE OPTICS LETTERS January 10, 2012

Dependence of wavefront errors on

nonuniformity of thin films

Hongji Qi (齐齐齐红红红基基基)

∗

, Meiping Zhu (朱朱朱美美美萍萍萍), Weili Zhang (张张张伟伟伟丽丽丽),

Kui Yi (易易易 葵葵葵), Hongbo He (贺贺贺洪洪洪波波波), and Jianda Shao (邵邵邵建建建达达达)

Key Laboratory of Material Science and Technology for High Power Lasers,

Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Shanghai 201800, China

∗

Corresp onding author: qhj@siom.ac.cn

Received April 2, 2011; accepted May 13, 2011; posted online July 29, 2011

In contrast to uncoated substrate, a nonlinear relationship of phase shift with the thicknesses of the thin

film makes the calculation of wavefront aberration complicated. A program is compiled to calculate the

wavefront aberration of multilayer thin film produced by thickness nonuniformity. The physical thickness

and the optical phase change on reflection are considered. As an example, the wavefront aberration of the

all-dielectric mirror is presented in ArF excimer lithography system with a typical thickness distribution.

In addition, the wavefront errors of the thin film at wavelengths of 193 and 633 nm are compared in the

one-piece and two-piece arrangements. Results show that the phase shift upon reflection of the thin film

pro duced by thickness nonuniformity is very sensitive to the incident angle, wavelength, and polarization.

OCIS codes: 310.6870, 000.4430, 050.5080.

doi: 10.3788/COL201210.013104.

In order to prevent the distortion of the beam profile,

the perfect flatness specification of surface should be

achieved for all the optical components. In a stadium-

sized laser facility – National Ignition Facility (NIF) at

the Lawrence Livermore National Laboratory – meter-

scale laser coatings, e.g., reflector, must meet the wave-

front requirement of λ/3 (λ = 1 053 nm)

[1]

. Because the

phase change is proportional to 1/λ, wavefront control is

more difficult for optical components in the ultra-violet

(UV) laser system compared with those in the infrared

system. In the UV lithographic system, the surface flat-

ness of optical components should be strictly controlled

to enhance the exposure resolution in the illumination,

imaging, and exposure systems. Compared with the

uncoated substrate, the flatness of the coated optical

components is determined by more factors

[2−6]

. In ad-

dition, the dependence of wavefront error on nonuni-

formity must be considered for the meter-scale-size

optical components. Ramsay et al. investigated the

multilayer dielectric reflecting surfaces in Fabry-Perot

interferometers

[7]

. Knowlden calculated the wavefront

errors produced by nonuniformity for dielectric-enhanced

infrared reflectors

[8]

.

In this letter, on the basis of the “figure error” func-

tion module in the Essential Macloed software, a program

was compiled to calculate the wavefront aberration due

to nonuniformity. The physical thickness and the optical

phase change on reflection due to thickness nonuniformity

were considered. The calculated results were input into

the MetroPro software to construct three-dimentional

(3D) surface morphology. As an example, the wavefront

aberration of the all-dielectric mirror was presented in

ArF lithography system. In addition, the wavefront of

the thin film at wavelengths of 193 and 633 nm were

compared with nonuniformity of 2%.

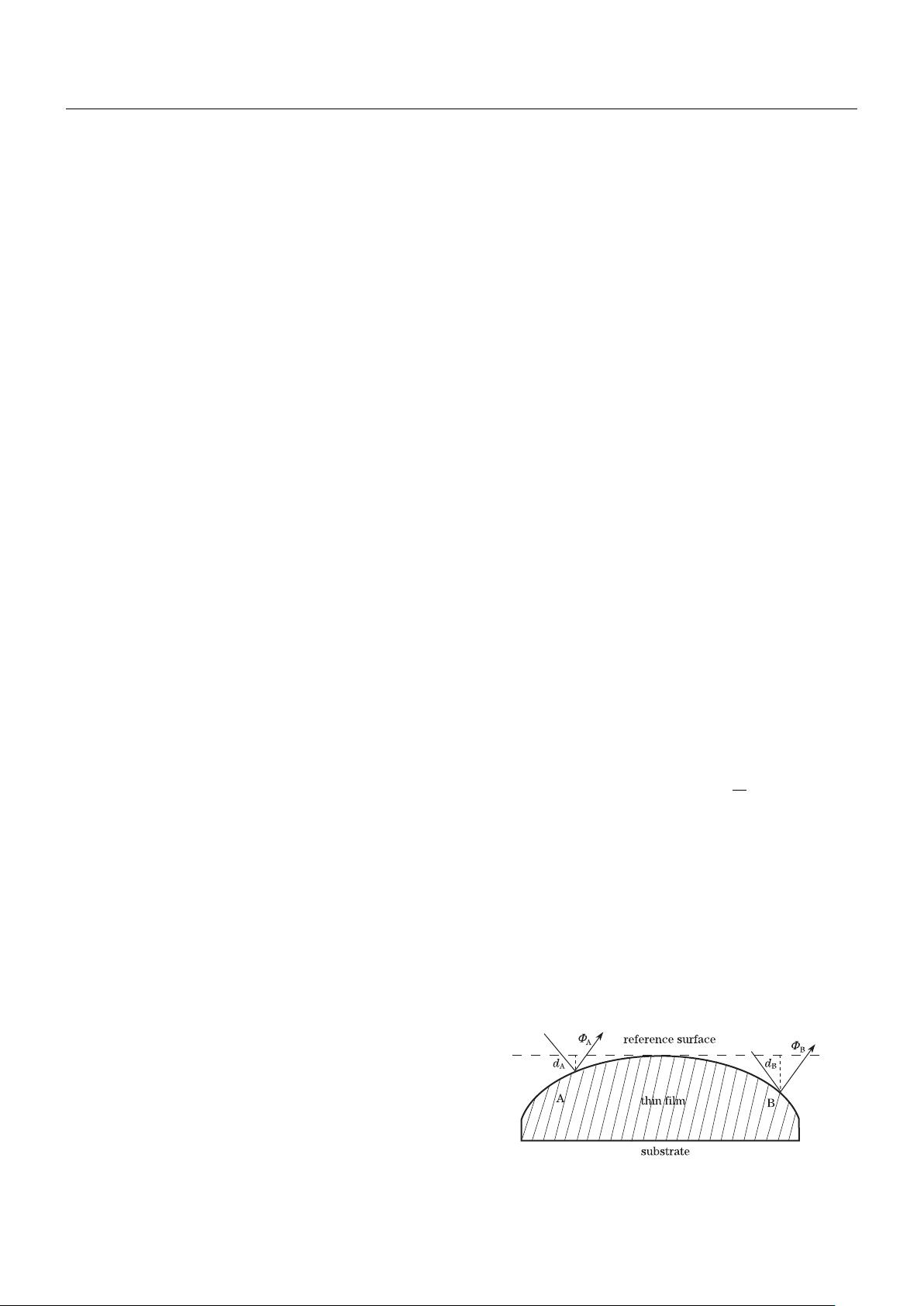

For an uncoated optical surface, wavefront distortion

is only related to figure error, i.e., the physical thickness

modulation of the surface. In the reflection approach,

the wavefront error is simply twice that of the surface.

In the case of coated optical surface, the phase shift

upon reflection of the multilayer thin film is involved in

the measurement of wavefront distortion, as shown in

Fig. 1. The total phase shift difference, Φ

A

–Φ

B

, de-

pends on the physical thickness difference, d

A

–d

B

, and

the reflective phase shift difference, Φ(d

A

)–Φ(d

B

). The

phase shift difference ∆Φ related to the physical thick-

ness difference, ∆d = d

A

–d

B

, is given by the formula ∆Φ

= ∆d/λ. The relationship between the reflective phase

shift difference Φ(d

A

)–Φ(d

B

) and the physical thickness

difference ∆d is relatively complicated.

In the case of isotropic film, the jth layer

film can be described by the characteristic matrix

h

cos δ

j

i sin δ

j

/η

j

iη

j

sin δ

j

cos δ

j

i

, where δ

j

=

2π

λ

n

j

d

j

cos θ

j

is re-

ferred as the phase thickness; n

j

and d

j

are the refractive

index and the physical thickness of the film, respectively;

η

j

is the effective optical admittance; θ

j

is the refractive

angle in the jth layer film. Combined with the substrate

or emergent medium with effective optical admittance

η

m

, the characteristic matrix of an assembly of q layers is

shown as

h

B

C

i

=

q

Q

j=1

h

cos δ

j

i sin δ

j

/η

j

iη

j

sin δ

j

cos δ

j

i

·

h

1

η

m

i

.

Here, B and C are the normalized electric and magnetic

fields at the front interface and can be used to extract

the properties of the thin film system, including the

phase change upon reflection, as shown by the equation

Fig. 1. Physical thickness and phase shift upon reflection pro-

duced by nonuniform coating.

1671-7694/2012/013104(4) 013104-1

c

° 2012 Chinese Optics Letters