"工业机器人自动运料小车路径规划与模块化设计研究"

版权申诉

137 浏览量

更新于2024-03-05

收藏 1.72MB DOC 举报

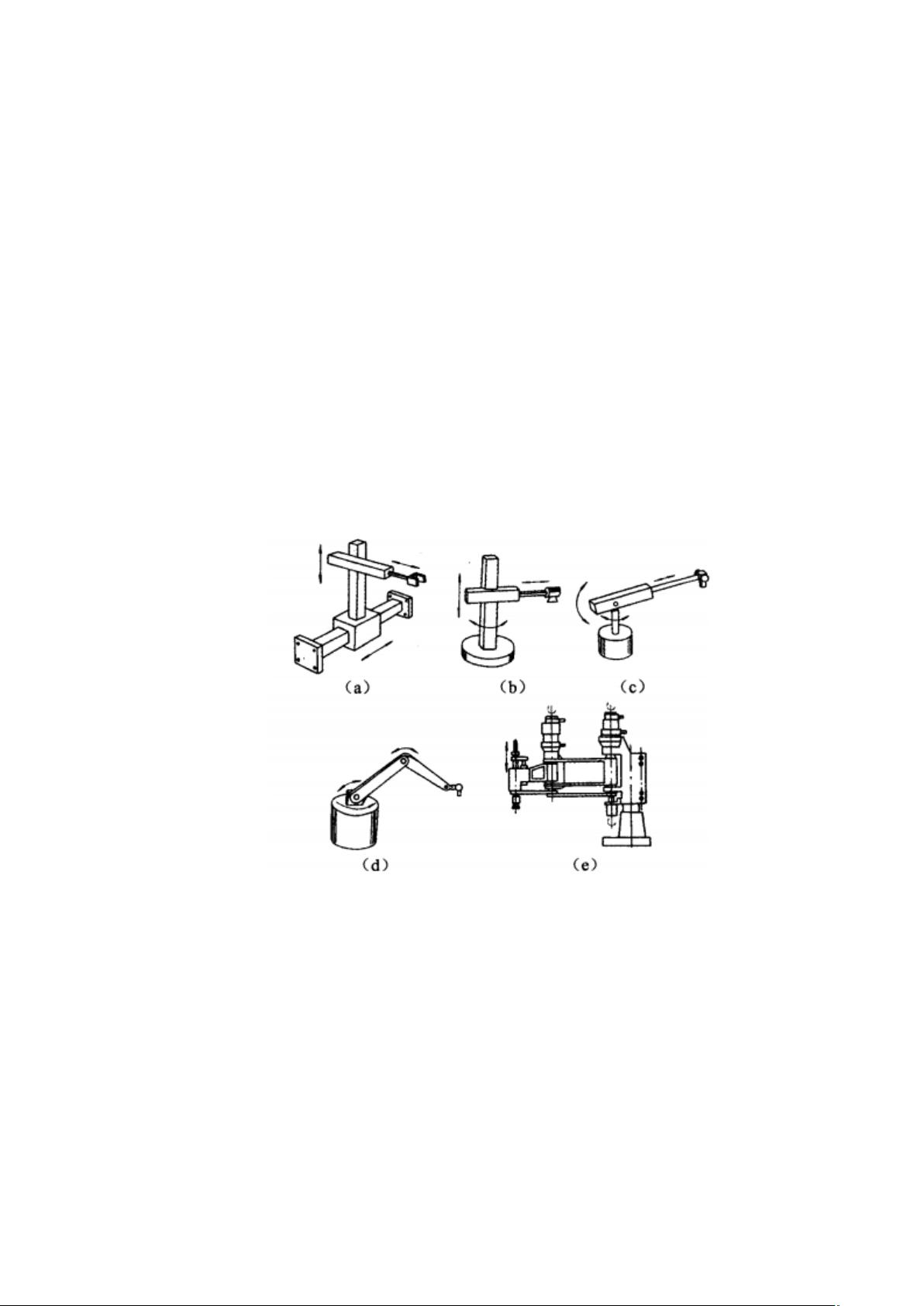

acturing industry evolving and automation increasing, the traditional fixed structure of industrial robots is proving to be inadequate. In order to meet the growing demands for automation, flexibility, and efficiency in material handling operations, the study of path planning for automated material handling vehicles has become crucial.

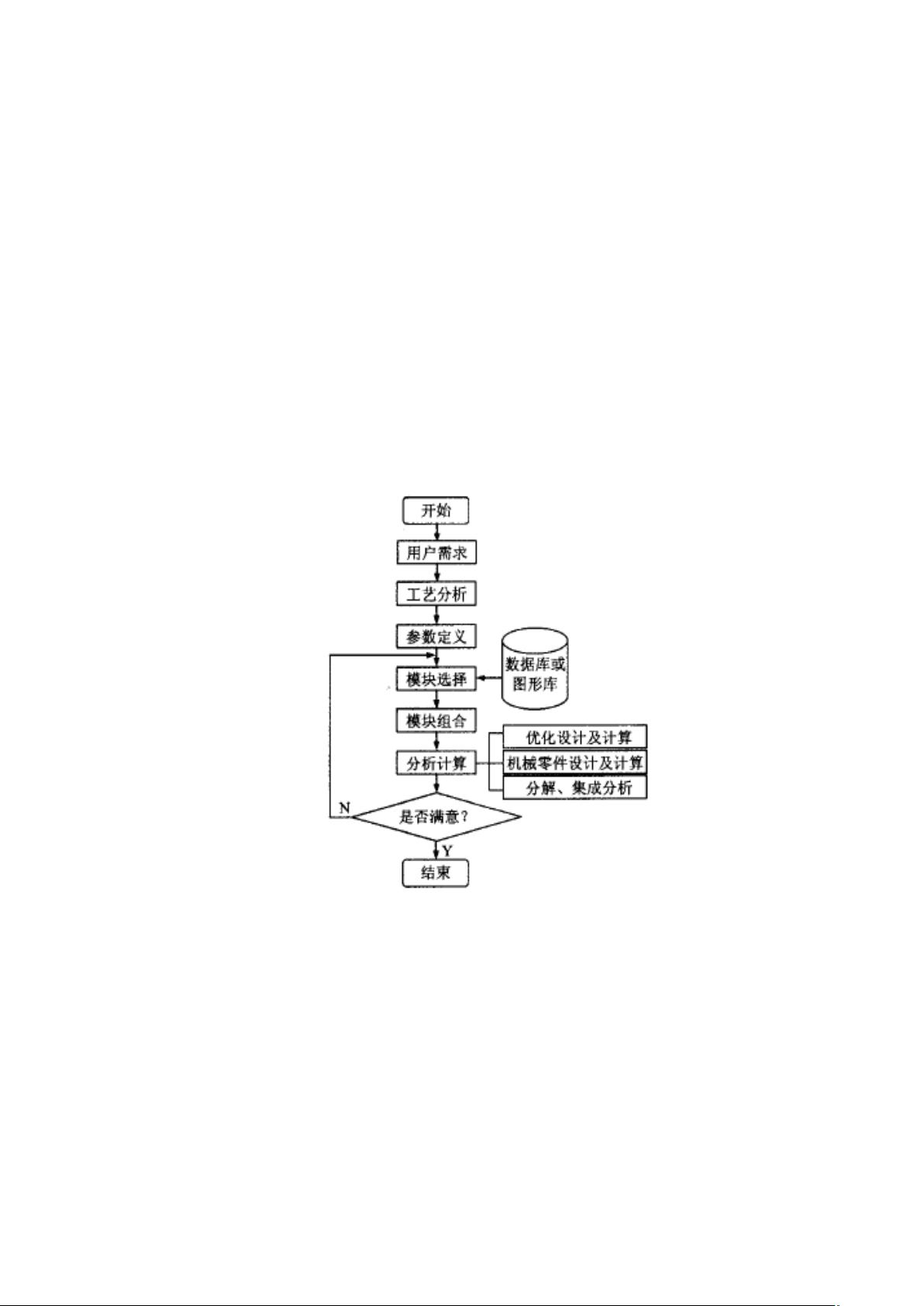

This paper presents a study on the design of a modular system for industrial robots in a production workshop. After analyzing the manufacturing processes and logistics systems of the workshop, a floor layout diagram is designed. By abstracting the floor layout of the rear-axle machining workshop, a path diagram for automated material handling vehicles is proposed using graph theory principles. Various path planning methods and genetic algorithm theory are studied, and a genetic algorithm is applied to solve a specific example in order to modularize the design of automated material handling vehicles.

Through the utilization of modular design, the limitations of traditional industrial robots are overcome. The flexibility and adaptability of the automated material handling vehicles are enhanced, allowing them to efficiently navigate the changing environment and tasks in the production workshop. This modular approach not only improves the overall efficiency of the manufacturing process but also sets the foundation for future advancements in automation and robotics in the industry.

In conclusion, the design of a modular system for industrial robots in a production workshop is essential for meeting the evolving demands of the manufacturing industry. By incorporating path planning and genetic algorithms, the modular design of automated material handling vehicles offers a flexible and efficient solution for material transport in the workshop. This research contributes to the advancement of automation and robotics in the industry, paving the way for more sophisticated and adaptable systems in the future.

2023-07-11 上传

2023-07-12 上传

2024-04-19 上传

2022-07-15 上传

2019-09-06 上传

2021-09-21 上传

老帽爬新坡

- 粉丝: 97

- 资源: 2万+

最新资源

- 算法

- ronald-mcdonald-house:费城罗纳德·麦克唐纳大厦(F2019)

- PINet

- windows6.11-KB976932-X86.exe.rar

- Diarios online sin registro-crx插件

- rest-api:用于Reconmap的REST API后端

- analytical_procedures_gl:出于审计目的执行日记帐分录测试!

- hello-word:丘丘球菌

- aws-playground:该存储库包含我对AWS的实验

- 园林绿化景观施工组织设计-园林景观工程施工方案

- abc196

- eslint-config

- AGU_PiedPiper.github.io:这是青山学院大学染色吹笛者编程爱好者协会的网站。

- DaisyDiff:Java 中 HTML 的视觉比较

- CouponBook:优惠卷卡包系统(慕课)

- 广场