0278-0046 (c) 2019 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission. See http://www.ieee.org/publications_standards/publications/rights/index.html for more information.

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication. Citation information: DOI 10.1109/TIE.2019.2962437, IEEE

Transactions on Industrial Electronics

IEEE TRANSACTIONS ON INDUSTRIAL ELECTRONICS

An Efficient CNN Model Based on Object-level

Attention Mechanism for Casting Defects

Detection on Radiography Images

Chuanfei Hu and Yongxiong Wang

Abstract—Automatic detection of casting defects on ra-

diography images is an important technology to automatize

digital radiography (DR) defect inspection. Traditionally, in

an industrial application, conventional methods are ineffi-

cient when the detection targets are small, local and subtle

in the complex scenario. Meanwhile, the outperformance of

deep learning models, such as the convolution neural net-

work (CNN), is limited by a huge volume of data with precise

annotations. To overcome these challenges, an efficient

CNN model, only trained with image-level labels, is first pro-

posed for detection of tiny casting defects in a complicated

industrial scene. Then, we present a novel training strategy

which can form a new object-level attention mechanism for

the model during the training phase, and bilinear pooling

is utilized to improve the model capability of detecting

local contrast casting defects. Moreover, to enhance the

interpretability, we extend class activation maps (CAM) to

bilinear CAM (Bi-CAM) which is adapted to bilinear archi-

tectures as a visualization technique to describe the reason

about the model output. Experimental results show that the

proposed model achieves superior performance in terms

of each quantitative metric and is suitable for most actual

applications. The real-time defect detection of castings is

efficiently implemented in the complex scenario.

Index Terms—Bilinear CAM, bilinear pooling, convolu-

tional neural network, digital radiography defect inspection,

object-level attention mechanism.

I. INTRODUCTION

A

LUMINIUM castings have been extensively applied to

various parts of automobile [1], aerospace [2], aircraft

[3] and electric devices [4] whose qualities affect the fatigue

behavior of overall product [5]. Due to the complexity and

diversity of casting process [6], defects are inevitable during

the process, such as gas holes, sand holes and flaws. And these

defects cannot be recognized by surface detection technology

when the defects have existed in the interior of castings.

In order to obtain the internal information and guarantee

the completeness of castings, radiography is often used for

nondestructive testing [7] which has been widely used in

quality controlling [8] and security inspection system [9].

Manuscript received August 06, 2019; revised November 01, 2019;

accepted December 12, 2019. This work was supported in part by the

National Natural Science Foundation of China under Grant 61673276.

(Corresponding author: Yongxiong Wang.)

C. Hu and Y. Wang are with Department of Control Science and Engi-

neering, University of Shanghai for Science and Technology, Shanghai

200093, China (w64228013@126.com; wyxiong@usst.edu.cn). They

contributed equally to this work.

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

( )

=

riu2

RP

LBP

,

195

25

25

Unrelated pallet

Unrelated background

Unrelated label Related casting Selected patch

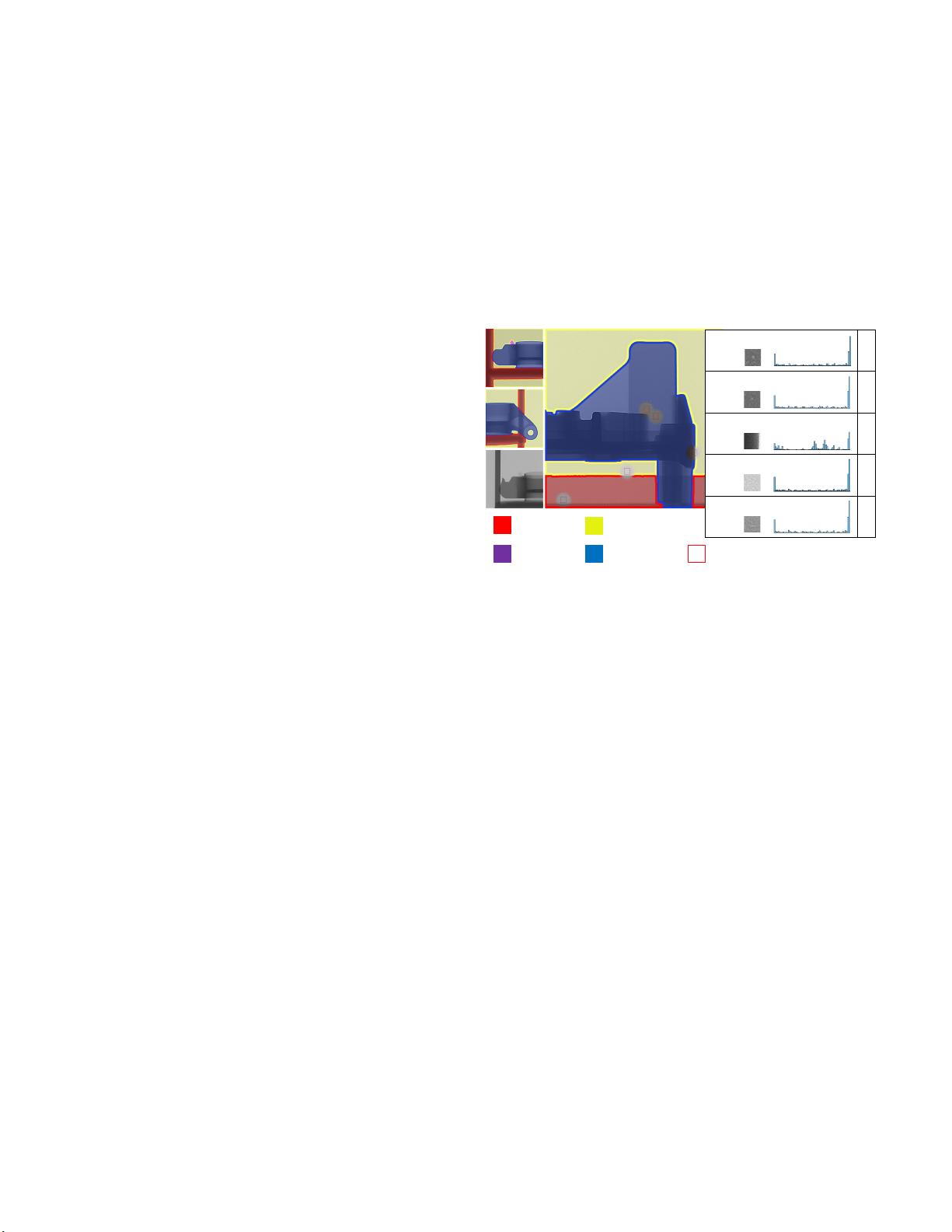

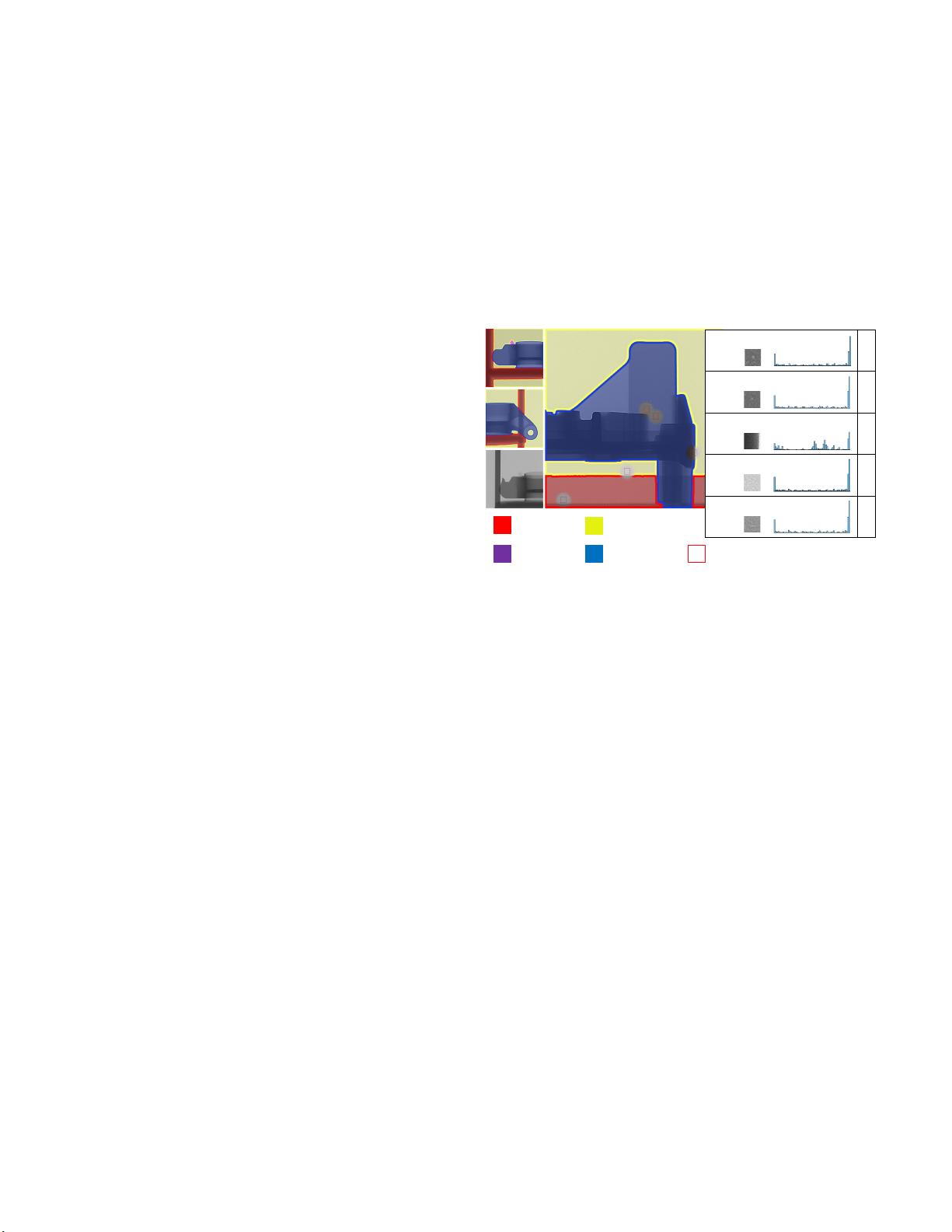

Fig. 1. On the left, the various regions of the radiography images are

masked by different colors. The result reveals the complicacy of the

scenario with various structures and positions of castings. Besides, we

extract uniform LBP features of the image patches which are selected

from related or unrelated areas. On the right, the Chi-square distances

of the LBP histograms are computed for the defect patch (in the first row

of the table) to the others. The comparison shows that the features of

defects are appeared in the other local regions. The locality attribute

of casting defects is revealed. Uniform LBP algorithm is denoted as

LBP

riu2

P,R

(·) where P represents the number of local neighbors (P = 8)

on a circle of radius R (R = 2).

In radiographic testing processing, most manufacturers rely

mainly on manual detection according to the experiences of

operators about the shape, brightness and contrast of castings.

Such manual method is not only mechanical and inefficient,

but also may cause ophthalmic diseases due to the high-

frequency illumination of the display. Consequently, the digital

radiography (DR) based automatic inspection system has been

one of the research focuses.

Over the past decades, conventional computer vision tech-

nology has extensive applications in many automatic inspec-

tion systems [10]–[13]. Handcrafted features and statistic

based machine learning models are often the main tools,

which use image algorithms to generate the feature vectors

of texture, color, shape and spectral cues, and then adopt sta-

tistical machine learning model to realize inspection systems.

With the advantage of simply and effective models, machine

learning methods achieve satisfactory performances in most

applications. However, the general drawback of conventional

methods is that their performances depend on the effective

representation extracted by handcrafted feature algorithms.

Designing a reliable and robust representation may be not