difference equations. At the higher level the system description is more abstract using discrete-event modeling. Based on the

decomposition of system dynamics, a control architecture can be build. Typically the controller designed for the top level is

then a discrete event supervisory controller (see, e.g., Ramadge and Wonham, 1989), while the lower-level controller is con-

trolling the continuous-time dynamics. The higher level and the lower level communicate by means of an interface that

translates continuous signals and discrete events. On the one hand, the discrete state of the higher layer triggers the contin-

uous-time dynamics in the lower layer. On the other hand, the signal of the lower layer generates an event to drive the

dynamics of the higher layer. For most of these systems the control design approach has been ‘‘divide and conquer’’, i.e.,

the higher-level and the lower-level controllers are designed independently and then linked by an interface that is designed

for the specific problem. In this paper we apply this decomposition to reduce the control complexity of an automated con-

tainer terminal.

The dynamics of transporting containers as considered in this paper can also be decomposed into the two levels. The

higher-level discrete-events can be the exchanging of a container by two types of equipment, while the lower-level contin-

uous-time dynamics can be the transport of a container by one piece of equipment. As will be detailed below, these two lev-

els can be linked by the operation time allowed for each piece of equipment for doing a certain operation. The higher-level

models can subsequently be used for scheduling of the discrete-event interactions of equipment; the lower-level model can

be used for control of each individual piece of equipment. Below the discrete-event model for the interaction of equipment

and the continuous-time model for each individual piece of equipment will be discussed in detail.

2.2. Higher-level discrete-event dynamics

At the higher level of the system the behavior is represented by discrete-event dynamics. The discrete-event dynamics

describe within which time interval and in which sequence a number of containers is handled by the available pieces of

equipment (i.e., QC, AGV, ASC).

The operations of the pieces of equipment can be represented as a three-stage hybrid flow shop (Ruiz and Vázquez-

Rodríguez, 2010). In a hybrid flow shop, each job has to pass through a number of stages. At every stage a number of identical

machines can be used in parallel to process the jobs. A job is processed by the same type sequence of machines and each job

requires a certain processing time in each stage.

In the three-stage flow shop that we consider, a job is defined as a complete process in which a container is transported

from the vessel to its stacking position. One job is processed by three types of equipment (QC, AGV and ASC). As a three-stage

hybrid flow shop, the operations by the three types of equipment are described in terms of three stages:

1. Stage 1: transport by the QC.

2. Stage 2: transport by one of the AGVs.

3. Stage 3: transport by one of the ASCs.

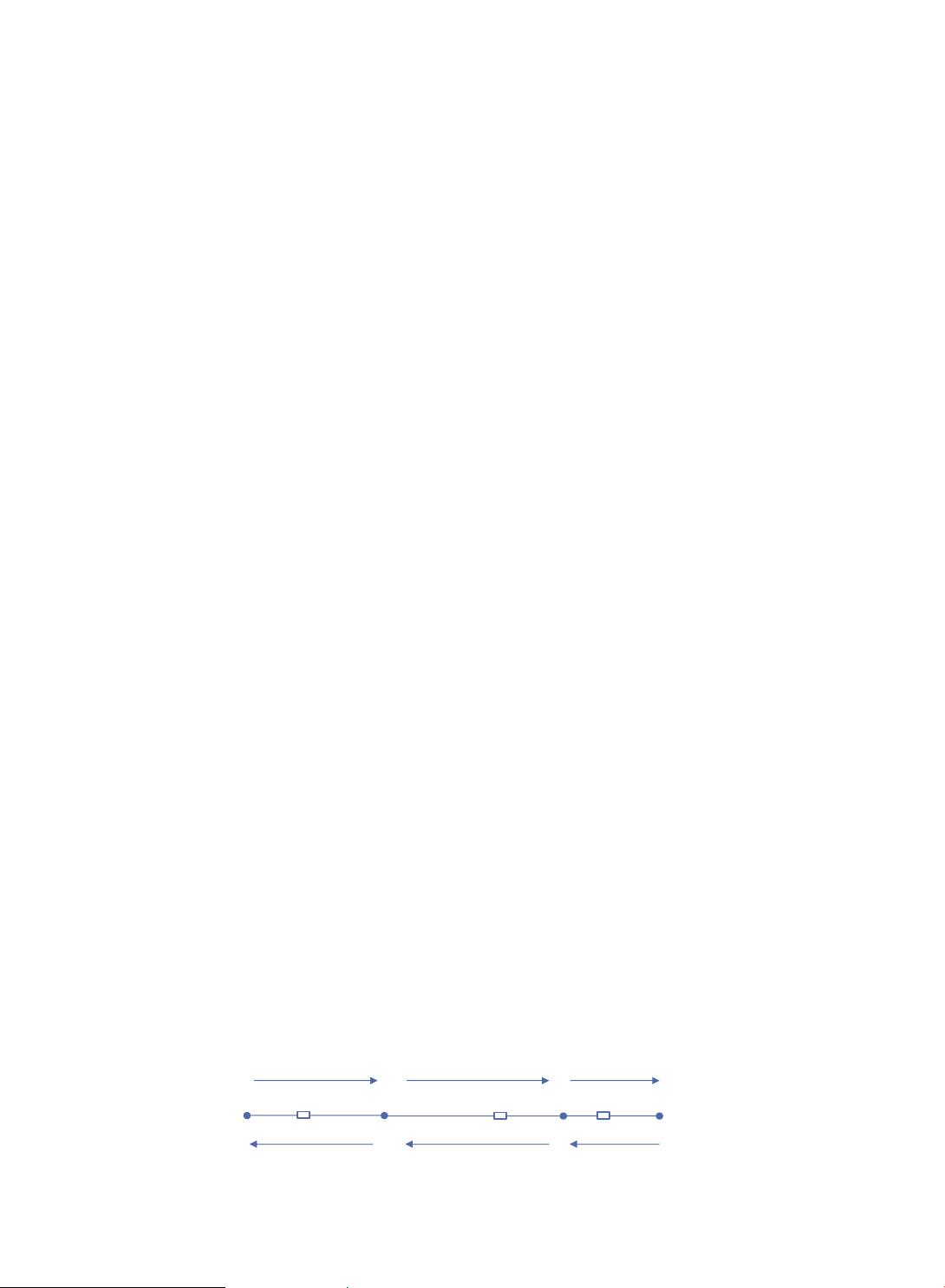

The operations by the three types of equipment are illustrated in Fig. 3.P

1

i

is defined as the place of container i in the

vessel. P

2

i

is the defined as the transfer point at which container i is transferred from a QC to an AGV. P

3

i

is defined as the

transfer point at which container i is transferred from an AGV to an ASC. P

4

i

is defined as the storage place of container i

in the stack.

In stage 1, there are two operations O

11

i

and O

12

i

. Operation O

11

i

is defined as the move of the QC from P

2

i

to P

1

i

for container

i and operation O

12

i

is defined as the move of the QC from P

1

i

to P

2

i

with container i. In stage 2, there are two operations O

21

i

and O

22

i

in which an AGV moves from P

2

i

to P

3

i

with container i and the AGV returns from P

3

i

to P

2

i

after unloading container i,

respectively. Two operations O

31

i

and O

32

i

are defined in stage 3, in which an ASC transports container i from P

3

i

to P

4

i

and the

ASC moves from P

4

i

to P

3

i

after unloading container i, respectively.

We next define the hybrid flow shop problem for our situation. The hybrid flow shop problem consists of finding the

sequences of jobs and equipment handling these jobs in an optimal way. Let there be n jobs of moving a container from

the vessel to the stack. Here we define

U

to be the set of jobs with cardinality of j

U

j¼n. In the hybrid flow shop problem,

the process of each operation in each stage has a time relationship: For a machine to process a job in a certain stage, there is a

time constraint for the preceding job and the successive job. For a certain job processed in different stages, there also exists a

time constraint to guarantee the sequence of operations in different stages. These time constraints are modeled as follows:

QC

AGV

ASC

Vessel

Stacking poin