C. Dombayci et al.

When other related methods and this study are connected, work is in the same research

line with Muñoz (2011) in terms of using functionalities of ontological models and the

knowledge introducing and collecting methods are managed generally. Additionally, this

work is not only on the interfacing of different elements in production systems but also

the solutions of mathematical programmes compared with Vegetti and Henning, (2015).

Modelling in the ontology is the main issue in this methodology, and similarly connecting

this model with programming skills. In general, problems occur in these connections and

more difficulties are expected in the solving of large scale problems.

5. Conclusions

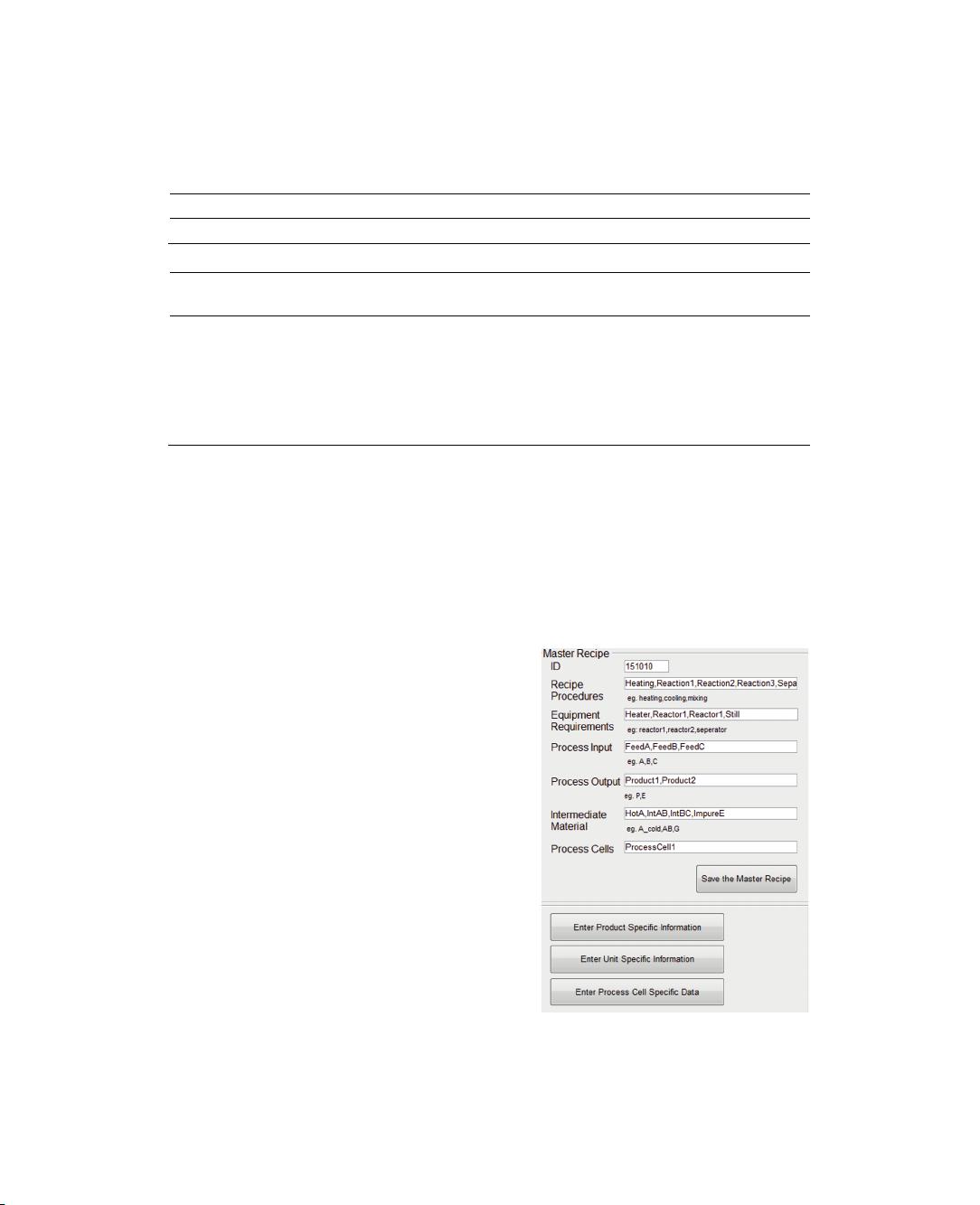

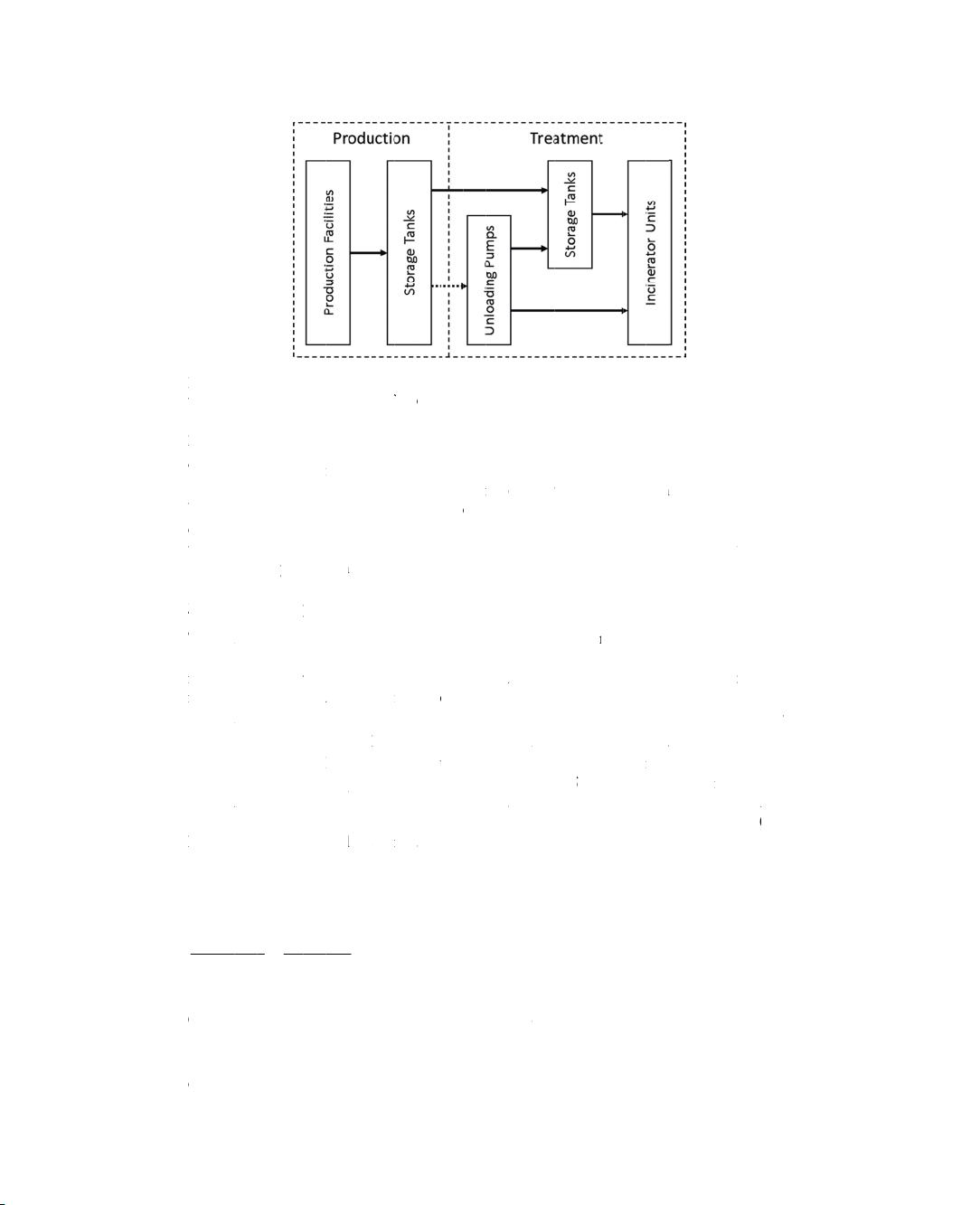

This paper proposes a methodology for integrated management of production systems. It

also presents a modular approach, and introduces a flexible way of managing production

in different process cells while incorporating the planning requirements. The data needed

to solve the different optimization problems in different production scenarios are

introduced to a general class of problem formulation through a single interface, and the

ontology determines the problem instance to be solved. The methodology showed

robustness and flexibility for developing more complex cases and may be adapted to use

different auxiliary tools (like sophisticated drawing tools to efficiently feed data to the

ontology).

Future work in this line involves developing a more general formulation to address other

classes of problems in hierarchical systems. Thus, extended formulations should be

implemented and the capacity of the methodology should be tested accordingly.

Additionally, exploring data base applications to connect module 1 with other modules

and investigating further data exchange applications will be investigated.

Acknowledgments

Financial support received from the Spanish Ministry of Economy and Competitiveness

and the European Regional Development Fund (research Project SIGERA, DPI2012-

37154-C02-01), the ‘Agencia de Gesti d’Ajuts Universitaris i de Recerca-AGAUR’ (2014

FI00305), the Mexican National Council for Science and Technology (CONACyT) and

the Research Group CEPEiMA (2014SGR1092), is fully appreciated.

References

BatchML. Batch Markup Language. Retrived September 2015 from:

http://www.mesa.org/en/BatchML.asp.

C. Dombayci, J. Farreres, H. Rodríguez, E. Muñoz, E. Capón-García, A. Espuña, M. Graells,

2015. On the process of building a process systems engineering ontology using a semi-

automatic construction approach. Comput-Aided Chem. Eng., 37, 941–946.

M. Fedorova, G. Sin, R. Gani, 2015. Computer-aided modelling template: Concept and

application. Comput Chem Eng, 85, 232-247.

E. Kondili, C.C. Pantelides, R.W. Sargent, 1993. A general algorithm for short term scheduling of

batch operations. Comput Chem Eng, 17, 211-227.

C. T. Maravelias, C. Sung, 2009. Integration of production planning and scheduling: Overview,

challenges and opportunities. Comput and Chem Eng, 33, 1919-1930.

E. Muñoz, E. Capon-Garcia, J. M. Lainez-Aguirrec, A. Espuña, L. Puigjaner, 2015. Supply chain

planning and scheduling integration using lagrangian decomposition in a knowledge

management environment. Comput Chem Eng, 72, 52-67.

E. Muñoz, 2011. Knowledge management technology for integrated decision support systems in

process industries. Phd, UPC.

M. Vegetti, G. Henning, 2015. An ontological approach to integration of planning and scheduling

activities in batch process industries. Comput-Aided Chem Eng, 37, 995-1000.

12