704 CHINESE OPTICS LETTERS / Vol. 6, No. 10 / October 10, 2008

Photonic crystal waveguides and their applications

Invited Paper

Yidong Huang (

ÀÀÀ

), Xiaoyu Mao (

fff

¡¡¡

), Chao Zhang (

ÜÜÜ

), Lei Cao (

ùùù

[[[

),

Kaiyu Cui (

www

mmm

), Wei Zhang (

ÜÜÜ

), and Jiangde Peng (

$$$

)

State Key Laboratory of Integrated Optoelectronics, Department of Electronic Engineering,

Tsinghua University, Beijing 100084

Received June 10, 2008

Two-dimensional (2D) slab photonic crystal waveguides (PCWGs) on silicon-on-insulator (SOI) wafer were

designed and fabricated. Full photonic band gap, band gap guided mode, and index guided mode were

observed by measuring the transmission spectra. Mini-stop-bands in the PCWG were simulated with

different structure parameters. Coupling characteristics of PCWG were investigated theoretically consid-

ering the imperfections during the fabrication process. It was found that suppressing power reservation

effect can realize both short coupling length and high coupling efficiency.

OCIS codes: 160.5298, 230.7370.

doi: 10.3788/COL20080610.0704.

Photonic crystal (PC) has been focused o n since it was

proposed by Yablonovitch

[1]

and John

[2]

in 1987, as it can

provide a novel way to guide, control, and manipulate

the photons. In various P C structures, two-dimensional

(2D) PC slabs, which a re normally ma de by periodically

patterning an array of air holes in high refractive index

materials slabs, have rec eived considerable a ttention in

recent years

[3−6]

for its in-plane band-gap and compati-

ble fabrication method with the traditional semiconduc-

tor wafer process. Inducing a line defect to the slab,

PC would form a band gap confinement PC waveguide

(PCWG)

[7]

, which is the fundamental part of most PC

based devices

[8]

.

This paper reviews our present research work on the

PCWG. A 2D slab PCWG on silicon-on-insulator (SOI)

wafer was designed a nd fabricated with traditiona l str ipe

waveguides for joint. By measuring the trans mission

sp e ctra, full photonic band gap, band gap guided mode,

and index guided mode were observed near 1.55 µm.

Mini-stop-bands in the PCWG were discussed with

different structure parameters. It is found that their

centre frequency is very sensitive to the refractive in-

dex of the substance filled in the holes of P C . Coupling

characteristics of PCWG were investigated theoretically

by considering the imperfections during the fabrication

process. It was found that s uppressing power reservation

effect can realize both short coupling length and high

coupling efficiency.

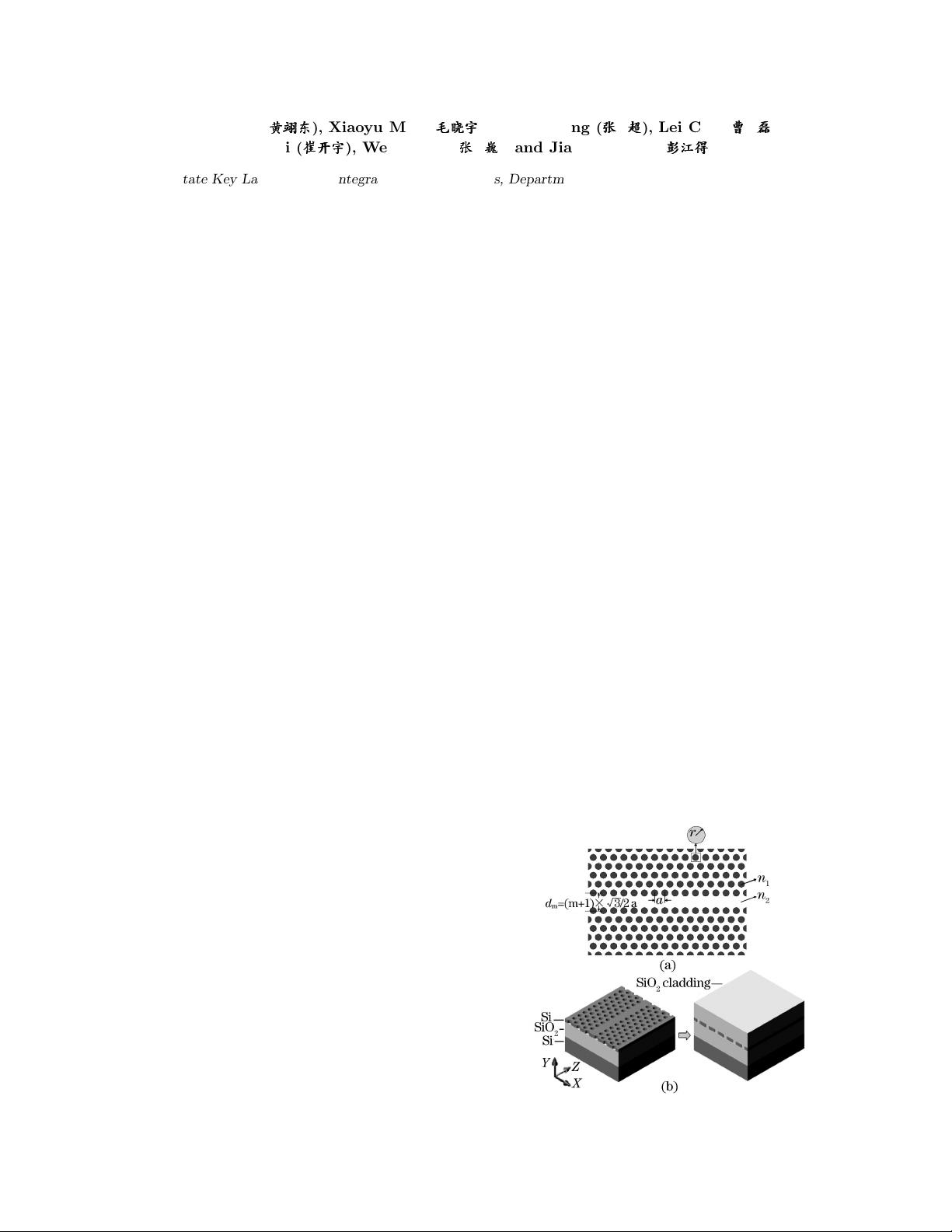

Figure 1(a) shows the simulation model of the PCWG.

The refractive index of the background and the substance

filled in the holes is n

2

and n

1

, res pectively. The lattice

constant is a, the radius of the air holes is r, and r/a is

taken as a key s tructure factor for the following discus-

sions because it decides the air-filling factor of the PCs

f ∝ (r/a)

2

. We designed the PCWG by plane wave

expansion method and finite-difference time-domain

(FDTD) simulation to ens ure the band gap g uided mode

around the wavelength of 1.5 µm. Here, s iz e enlarge was

considered because hole size would be enlarged during

the fabrication. Line defect PCWGs along Γ- K direction

were fabricated. Figure 1(b) shows the structur e . SOI

wafer with a 200-nm-thick silicon film on the top and a

3000-nm-thick buried SiO

2

layer was used. Using a ZEP-

520A resist mask, PC pattern was generated perfectly

by electron beam (EB) lithography. Then an induc-

tively coupled plasma (ICP) dry etching was employed

to transfer the pattern to the silicon film. After remov-

ing the resist mask, a 600-nm-thick SiO

2

cover layer was

deposited on the surface to form a symmetry SiO

2

clad

structure for reducing the radiation loss in the vertical

direction. Finally, we ground the wafer to about 100-µm

thick, and cleaved them into ab out 1 mm-long samples

for measurement. We removed some sample’s upper SiO

2

cover layer by HF etching to verify the size and shape

of the holes by scan electron micros c op e (SEM). Figure

2 are the SEM pictures for a slab PC without line de-

fect and a line defect PCWG along Γ-K direction. The

period a and the radius r of the PC are 380 nm and 90

nm, re spec tively. The coupling loss between a tapered

fiber and a stripe waveguide was measured. For tapere d

fiber with 1.7-µm fo c us diameter, we found that a 2-µm

wide waveguide had the lowest coupling loss of −7 dB

per facet. Therefore 2-µm-wide waveguide was used for

Fig. 1. (a) Simulation model and (b) symmetry SiO

2

clad

structure.

1671-7694/2008/100704-05

c

2008 Chinese Optics Letters