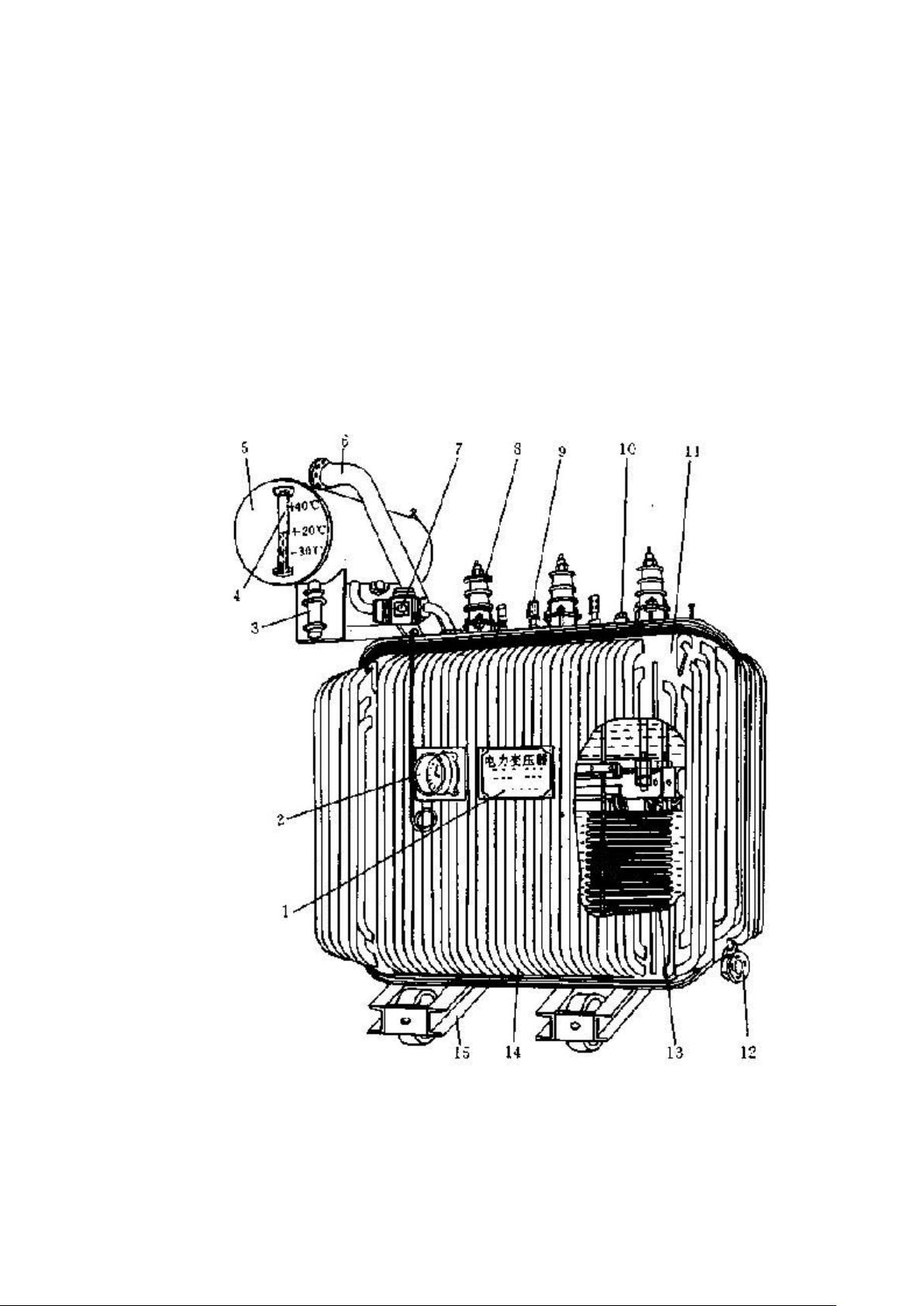

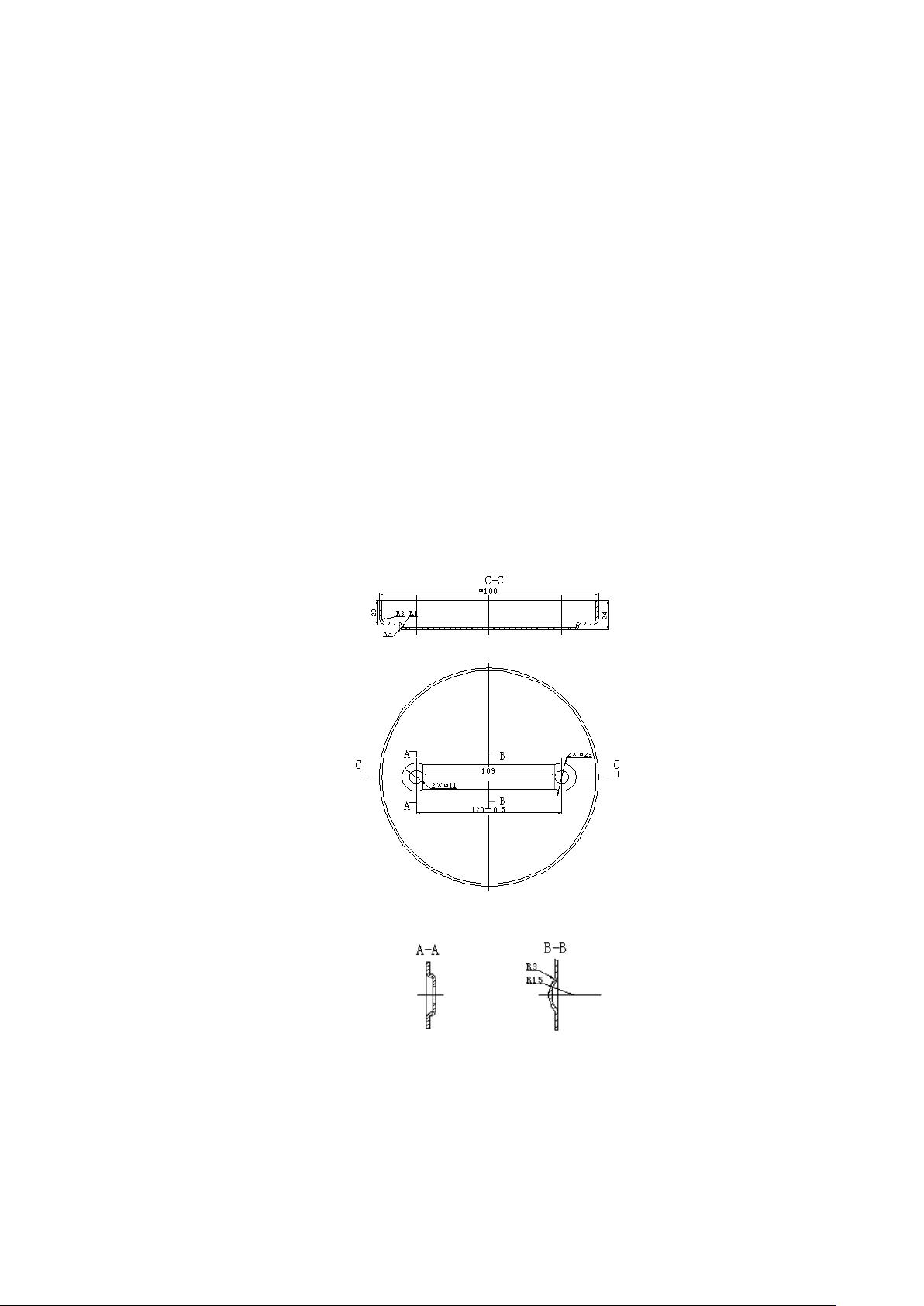

"变压器储油柜端盖模具设计及工艺分析"

版权申诉

53 浏览量

更新于2024-03-02

收藏 1.31MB DOCX 举报

Abstract

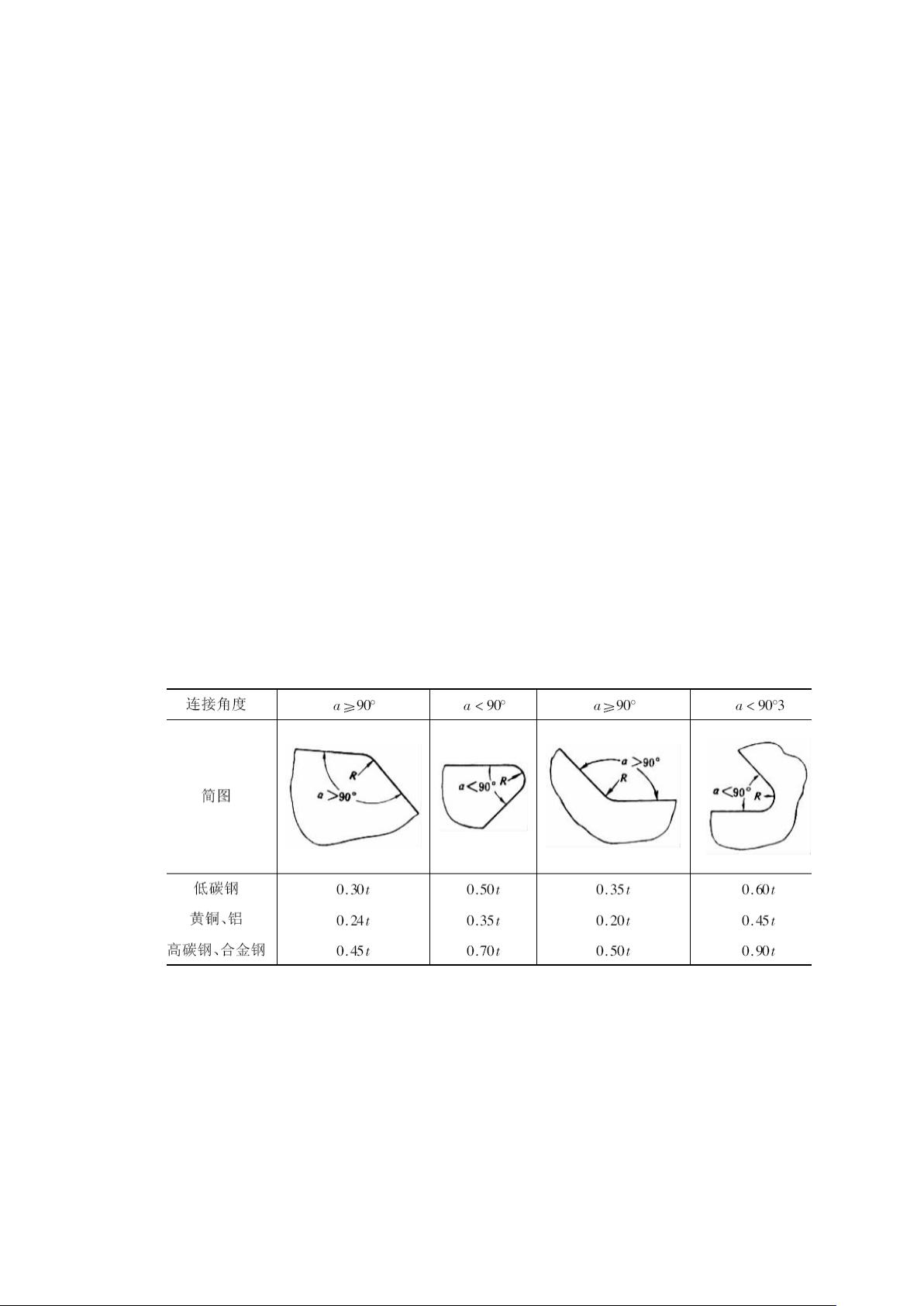

The structure and processing property of bellows oil conservator end cover for transformers were analyzed. The blank dimensions and pressing force were calculated, with the aim of improving the production efficiency of the end cover. A combined die for blanking, deep drawing, and punching was designed to achieve this goal. Through process analysis and structural design, the feasibility of the combined die was demonstrated, ensuring the quality of the product. In the mold design process, existing knowledge and resources were fully utilized to improve speed and efficiency. Pro/E surface design function was used to quickly calculate the surface area. The stamping die design software was employed to rapidly design the stamping die, with the die strength being inspected. The practice proved that the design speed and efficiency were indeed improved. In this mold design, due to the large stripping force, the advantage of using a combination of large spring force was used to solve this problem. In the mold structure, the punch plate was used as the locating element of the convex mold. However, the small distance between the locating elements could easily cause the convex mold to break. Therefore, a concave mold guiding the convex mold was designed to enhance the strength of the convex mold.

Keyword: Blank, Deep Drawing, Punching, Combined Die, Mold Structure

从上述内容可以得出,模具设计是通过对变压器储油柜端盖的结构和成形工艺进行分析和计算,提出了一套集成落料、拉深和冲孔工序的复合模具结构。同时,在模具设计中,利用了现有的知识和资源,通过Pro/E曲面设计功能和冲模设计手册软件版,提高了设计速度和效率。设计中还解决了卸料力大的问题,并增强了凸模的强度。这些设计和优化措施保证了产品质量,并提高了生产效率。

2021-10-10 上传

2021-10-01 上传

2021-11-18 上传

2019-09-14 上传

2022-01-06 上传

2024-04-08 上传

2022-07-11 上传

南抖北快东卫

- 粉丝: 79

- 资源: 5587

最新资源

- BottleJS快速入门:演示JavaScript依赖注入优势

- vConsole插件使用教程:输出与复制日志文件

- Node.js v12.7.0版本发布 - 适合高性能Web服务器与网络应用

- Android中实现图片的双指和双击缩放功能

- Anum Pinki英语至乌尔都语开源词典:23000词汇会话

- 三菱电机SLIMDIP智能功率模块在变频洗衣机的应用分析

- 用JavaScript实现的剪刀石头布游戏指南

- Node.js v12.22.1版发布 - 跨平台JavaScript环境新选择

- Infix修复发布:探索新的中缀处理方式

- 罕见疾病酶替代疗法药物非临床研究指导原则报告

- Node.js v10.20.0 版本发布,性能卓越的服务器端JavaScript

- hap-java-client:Java实现的HAP客户端库解析

- Shreyas Satish的GitHub博客自动化静态站点技术解析

- vtomole个人博客网站建设与维护经验分享

- MEAN.JS全栈解决方案:打造MongoDB、Express、AngularJS和Node.js应用

- 东南大学网络空间安全学院复试代码解析