728 IEEE TRANSACTIONS ON AUTOMATION SCIENCE AND ENGINEERING, VOL. 10, NO. 3, JULY 2013

used to select submodels. However, the size of the ensemble

numbers must be given manually. Recently, Wang et al. pro-

posed an evolutionary algorithm-based selective ensemble al-

gorithm with size control [40]. It shows the optimal ranges for

number of ensemble submodels is 2

8, which is an important

conclusion.

Surveys of the selective ensemble m odeling approach show

how to apply this modeling m etho d, in practice, problem is one

of the future directions [41], [42]. Thus, how to use selective

ensemble modeling technology for estimating ML parameters is

a valuable practice problem. It is very necessary and significant.

D. Motivation

Constructing effective selective ensem ble M L param eters’

models, the following pro blem s have to be addressed.

The first problem is how to construct ensembles. In this paper,

aim at the high-dimensional problem of the frequency spec-

trum, only “manipulating th e input features” approach is fo-

cused. Thus, we used the feature subsets selection and extraction

method in our recently published journal paper, see [22].

The second pro blem is how to construct effective submodels.

Modeling the high-dim e nsio nal frequency spectrum, the “curse

dimensionality” p rob lem has to be o verco me. Feature extraction

method based on kernel principal component analysis and fea-

ture selection method based on genetic algorith m- par tial least

squares have their disadvantage. The extracted features only

relate to most of the change of the frequency spectrum. The

selected features have to drop out some original features with

some criteria. KPLS can construct effective model using ex-

tracted latent features relative to i npu t and output data simul-

taneously, which is used to model ML parameters.

The third problem is how to select and weight submodels.

In this paper, we give a new perspective for the selective en-

semble mo deling approach. Now, we have known, three basic

steps for the selective ensemble: the selection of ensemble or-

ganization, the selection of ensemble submodels, and the combi-

nation methods of submodels [43]. When the ensemble organ-

ization and the com bination methods have been selected, the

problem of the selectiv e ensemble modeling can be looked at as

an optimal problem of select submodels. Minim um mean square

error-based AWF algorithm is always used to obtain the op-

timal observation value in a multisensor system. The branch and

bound (BB) algorithm is always used for finding optimal solu-

tions of various optimization problems. Large candidate subsets

are discarded by using upper and lower e stimated bounds of the

quantity being optimized [44]. It has been used widely in the fea-

ture selection problems [45]. When the nu mb ers of the features

exceeds 30, the computing consumption has to b e considered.

However, for our ML parameters modeling problem, number

of submodels based on feature subsets are limited. Therefore,

combining with the weightin g algorithm, BB algor ithm can be

used to obtain the optimal subm od els.

Motivated by the above discussions, a selective ensemb le

approach for modeling ML is proposed in this paper. First, the

shell v ibration and acoustical spectra are calculated. Then, the

frequency spectrum clustering algorithm is used to partitio n

the spectrum automatically to obtain the spectral segments; the

MI-based feature selection algorithm is used to select feature

subsets of the local peaks and frequency subbands. The candi-

date feature subsets include spectral segments, features of local

peaks, frequency subbands, origin fu ll spectru m and mill motor

current signal. Finall y, th e KPLS algorithm is u sed to construct

the nonlinear ML parameters models with each feature subset;

the BB and AWF algorithms are used to select submodels and

calculate the weighting coefficients.

This paper is divided into the following sections. Section II

describes the mill load of the grinding p ro cess. Section III

presents the strategy o f selective ensemble multisensor in-

formation approach. Section IV presents the realization of

the proposed approach in detail. Section V presents the ex-

perimental results and discussion. Section VI presents the

conclusions.

II. M

ILL LOAD (ML) DESCRIPTION OF THE GRINDING PROCESS

A. Description of Mill Load a nd Mill Load Parameters

Mill load (ML) is one of the key parameters and affected by

lots of factors. ML can be estimated by using parameters inside

of the ball mill, such as material to ball volume ratio (MBVR),

pulp density (PD) and charge volume ratio (CVR) [11]. The

mapping among the ML status, ML and ML parameters can be

represented as

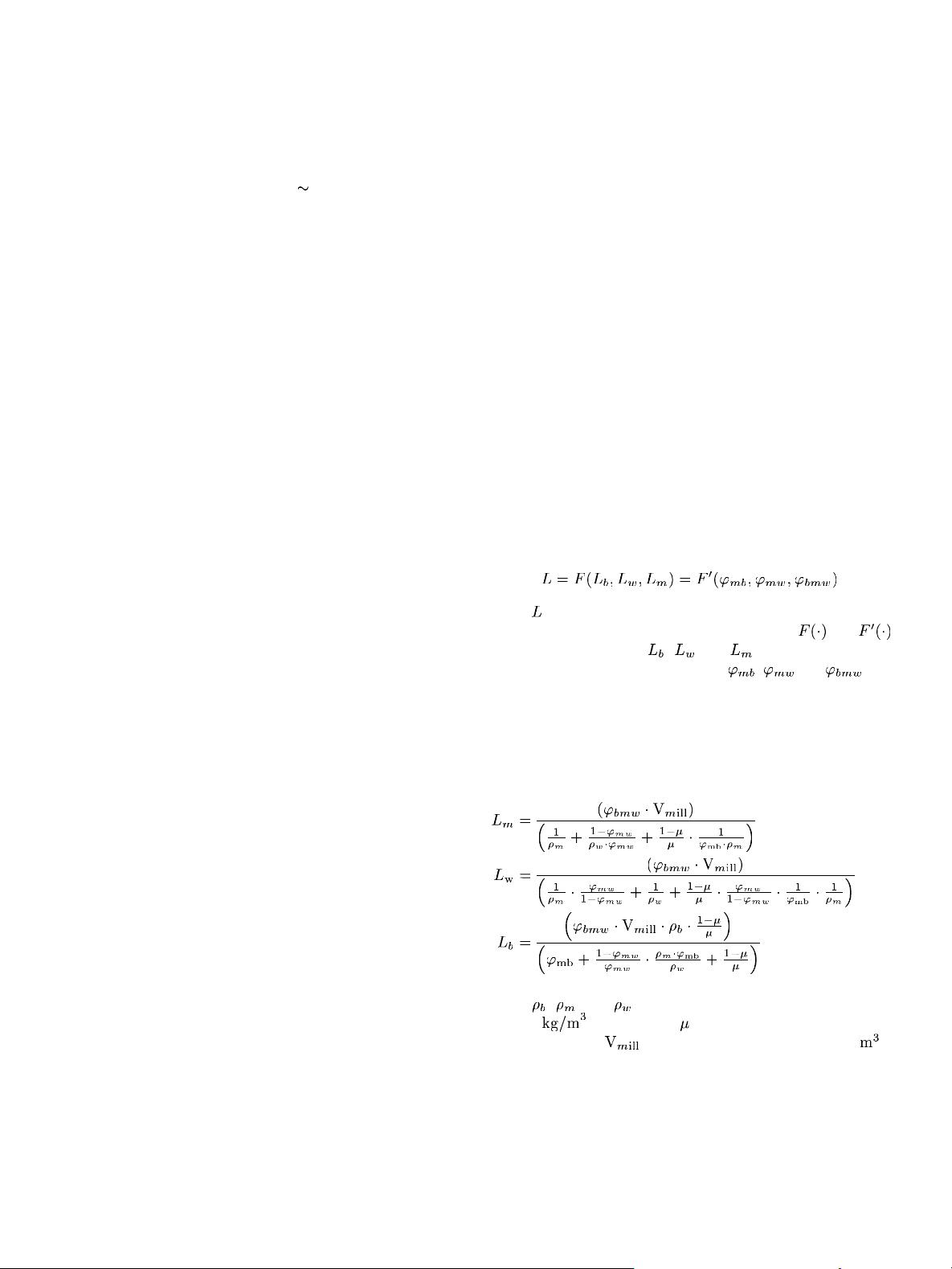

(1)

where

represents the status of ML, which usually is divided

into low-load, normal load, and ove rload status;

and

are unknown functions; , and represent ball, water

and material load, respectively, in kg;

, and rep-

resent MBVR, PD, and CVR, respectively.

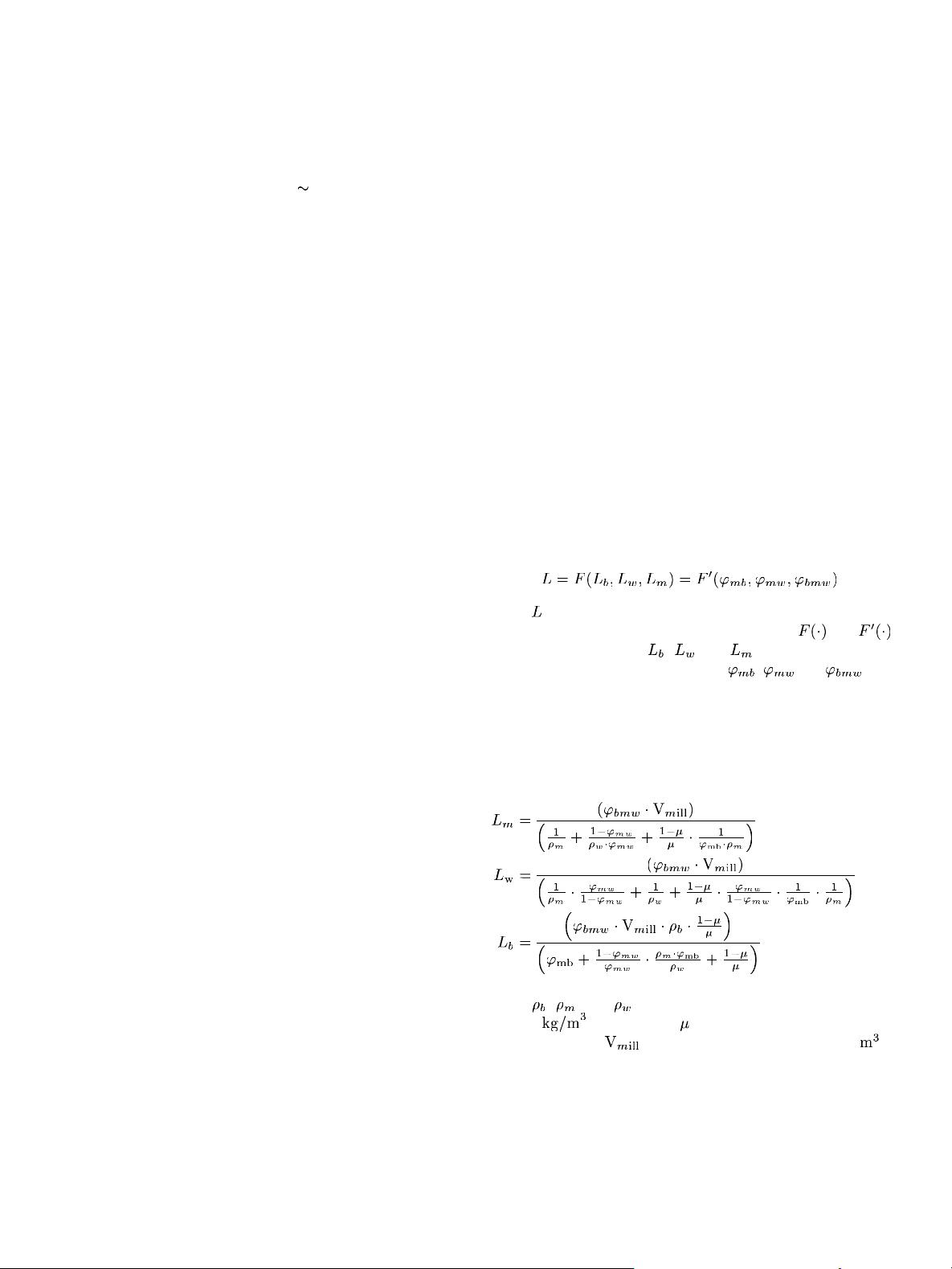

Combining with the mill volume, the density of the material,

ball and water, and the interstice rate of the balls, we can ob-

tained the mineral, b all and water load inside the mill based on

the MBVR, PD, and CVR w ith the followin g equations:

(2)

(3)

(4)

where

, ,and are the density of the ball, mineral and

water in

, respectively; is th e interstice rate of the balls,

whichis0.38and

is the i nner volume of the mill in .

Remark: Equations (2)–(4) are just a theoretical com pu tin g

based on the definition of ML parameters. The revision of these

equations need more research based on the mechanical analysis

and experiments.

B. Grinding Process Description

The fundam ental objective o f a grinding circuit (GC) is to

liberate valuable minerals in such a way that the su bsequen t

separation process can be operated at its maximum economic