"基于三菱PLC的水泥厂窑头喂煤系统设计及控制研究"

98 浏览量

更新于2024-03-15

收藏 1.35MB DOC 举报

随着建筑行业的持续发展,对水泥产量和质量的要求也越来越高。水泥煅烧作为水泥生产过程中至关重要的一环,喂煤系统中煤粉的连续、均匀喂料是保障煅烧工作顺利进行的关键。然而,由于国外喂煤系统控制的核心、编程语言及许多元器件国内无法替代,难以日常维护,因此本设计采用国内高性价比元器件和通用的三菱PLC代替部分国外喂煤系统的元件。

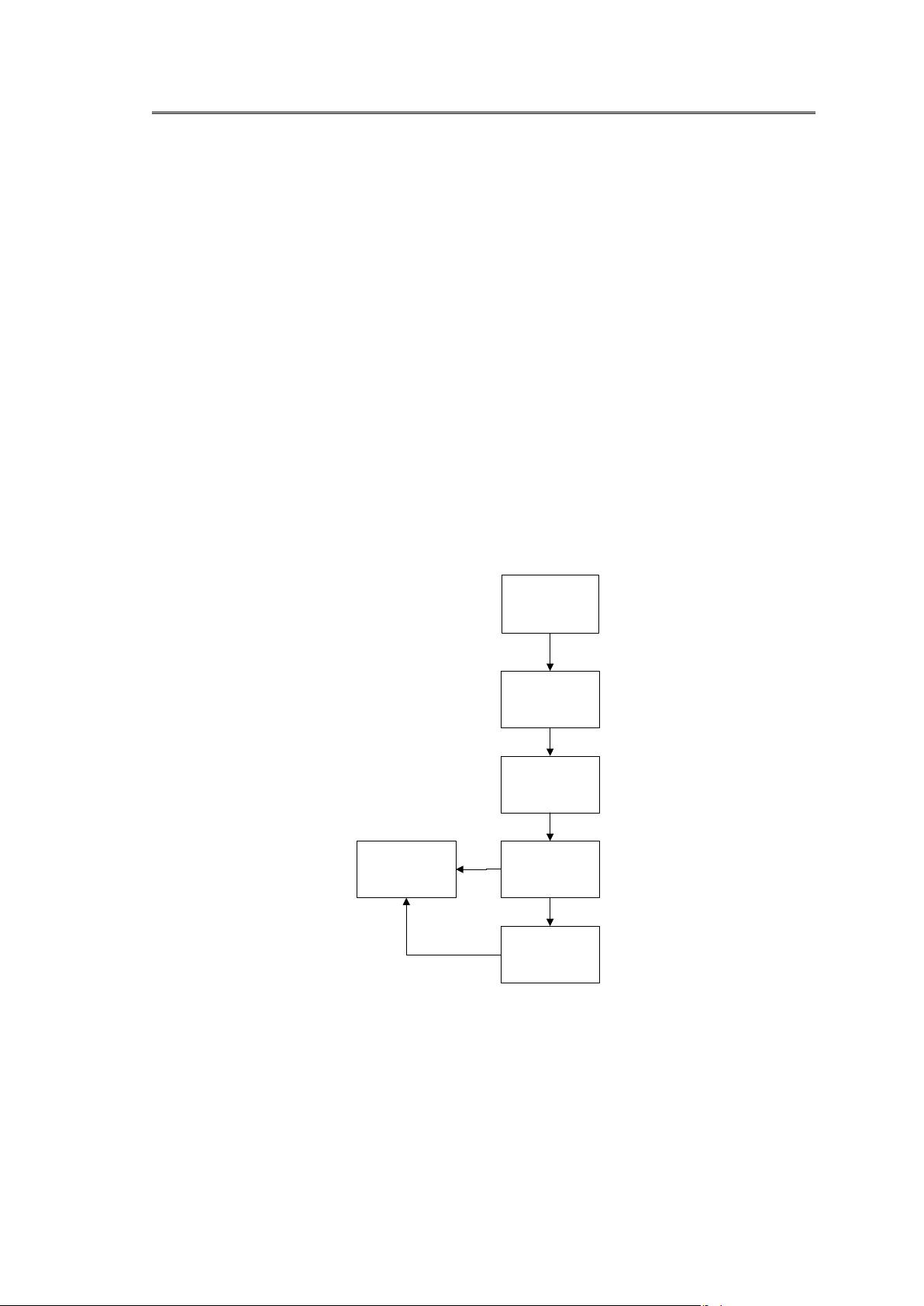

本喂煤系统的控制目标是能够向窑头连续、均匀地喂煤,并实现5‰的喂煤精度。设计以三菱PLC为控制核心,通过称重传感器测量转子秤中煤粉的重量,并通过变频器得出转子盘的旋转速度。PLC通过高速脉冲测量单元和A/D转换单元将煤粉的重量和速度转化为数字量,经过系统运算处理后得出煤粉的瞬时流量,再与给定量进行比较,并通过PID算法实现最佳控制效果,使煤粉的瞬时流量能够跟踪给定流量。

关键词:转子秤,PLC,PID,喂煤系统,A/D转换。 洛阳理工学院毕业设计(论文)IIIThe cement kiln head feeding coal system based on Mitsubishi PLC design

Abstract: With the continuous development of the construction industry, the demand for cement production quantity and quality is increasing. Cement calcination is an important part of the cement production process, and the continuous and uniform feeding of coal powder in the coal feeding system is the basis for the smooth operation of calcination. However, due to the core control, programming language, and many components of foreign coal feeding systems that cannot be replaced domestically, it is difficult to maintain on a daily basis. Therefore, this design will use domestic high-cost-effective components and common Mitsubishi PLC to replace some of the components in foreign coal feeding systems.

The control objective of this coal feeding system is to continuously and uniformly feed coal to the kiln head and achieve a coal feeding accuracy of 5‰. The design uses Mitsubishi PLC as the control core, with the rotary scale measuring the weight of coal powder through weighing sensors, and the speed of the rotary disk determined by the frequency converter. The PLC converts the weight and speed of the coal powder into digital quantities through high-speed pulse measurement units and A/D conversion units, calculates the instantaneous flow rate of the coal powder after system operation, compares it with the given quantity, and achieves the best control effect of tracking the given flow rate through the PID algorithm.

Keywords: rotary scale, PLC, PID, coal feeding system, A/D conversion.

点击了解资源详情

点击了解资源详情

2021-09-18 上传

2019-10-19 上传

2021-09-26 上传

2021-10-06 上传

matlab大师

- 粉丝: 2721

- 资源: 8万+

最新资源

- Java集合ArrayList实现字符串管理及效果展示

- 实现2D3D相机拾取射线的关键技术

- LiveLy-公寓管理门户:创新体验与技术实现

- 易语言打造的快捷禁止程序运行小工具

- Microgateway核心:实现配置和插件的主端口转发

- 掌握Java基本操作:增删查改入门代码详解

- Apache Tomcat 7.0.109 Windows版下载指南

- Qt实现文件系统浏览器界面设计与功能开发

- ReactJS新手实验:搭建与运行教程

- 探索生成艺术:几个月创意Processing实验

- Django框架下Cisco IOx平台实战开发案例源码解析

- 在Linux环境下配置Java版VTK开发环境

- 29街网上城市公司网站系统v1.0:企业建站全面解决方案

- WordPress CMB2插件的Suggest字段类型使用教程

- TCP协议实现的Java桌面聊天客户端应用

- ANR-WatchDog: 检测Android应用无响应并报告异常