IEEE PHOTONICS TECHNOLOGY LETTERS, VOL. 27, NO. 8, APRIL 15, 2015 813

Plasmonic Hologram Based on

Metallic Nanowire Gratings

Xin Sheng, Jie Cui, Jun Zheng, and Zhi-Cheng Ye

Abstract—In this letter, we present a colorful plasmonic

hologram which is polarization sensitive—the diffraction

efficiency of transverse magnetic light is more enhanced than

that of the transverse electric light. The character is caused by

longitudinal plasmonic waveguiding effects in the periodic metal-

insulator-metal waveguides. These patterns in the hologram even

lead to the merits of wide incident angle and working bands. This

letter affords a new approach to fabricate highly efficient and

polarization-dependent hologram, which is potentially applicable

to stronger anticounterfeiting and compatible with liquid crystal

for dynamic 3-D displays.

Index Terms—Holography, optical polarization, surface

plasmon, waveguide modes.

I. INTRODUCTION

H

OLOGRAPHY, recording both amplitude and phase of

light fields, has been applied to many fields such as

holographic interferometry and anti-counterfeiting [1], [2].

In particular, holographic imaging enjoys great popularity in

three-dimensional (3D) displays [3]. Unlike stereoscopy which

always leads to visual discomfort and fatigue [4], holography

is capable of providing real 3D images without glasses.

In spite of those advantages, low diffraction efficiency

and limited viewing angle are still hindering the practical

application of holography, especially in relief hologram which

dominates the commercial market of anti-counterfeiting and

decoration.

Manuscript received November 18, 2014; revised December 25, 2014;

accepted January 6, 2015. Date of publication January 12, 2015; date of

current version March 19, 2015. This work was supported in part by the Ph.D.

Programs Foundation through the Ministry of Education, China, under Grant

20100073120034, in part by the Major State Basic Research Development

Program (973 Program) of China under Grant 2013CB328804, in part by

the National Natural Science Foundation of China under Grant 11374212,

Grant 61370047, Grant 61007025, and Grant 51235007, and in part by the Key

Laboratory of High Energy Laser Science and Technology, China Academy

of Engineering Physics, Mianyang, China, under Grant 2012HCF03.

X. Sheng and J. Cui are with the National Engineering Laboratory

for TFT-LCD Materials and Technology, Department of Electronic Engi-

neering, Shanghai Jiao Tong University, Shanghai 200240, China (e-mail:

rai@sjtu.edu.cn; cuijie@sjtu.edu.cn).

J. Zheng is with Key Laboratory for Laser Plasmas (Ministry of Educa-

tion), Department of Physics and Astronomy, IFSA Collaborative Innovation

Center, Shanghai Jiao Tong University, Shanghai 200240, China (e-mail:

jzheng@sjtu.edu.cn).

Z.-C. Ye is with National Engineering Laboratory for TFT-LCD Materials

and Technology, Department of Electronic Engineering, Shanghai Jiao Tong

University, Shanghai 200240, China, and also with the State Key Laboratory

on Integrated Optoelectronics, Institute of Semiconductors, Chinese Academy

of Sciences, Beijing 100083, China (e-mail: yzhch@sjtu.edu.cn).

This paper has supplementary downloadable material at

http://ieeexplore.ieee.org, provided by the authors. The file consists of

Media 1. The material is 1.03 MB in size.

Color versions of one or more of the figures in this letter are available

online at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/LPT.2015.2390776

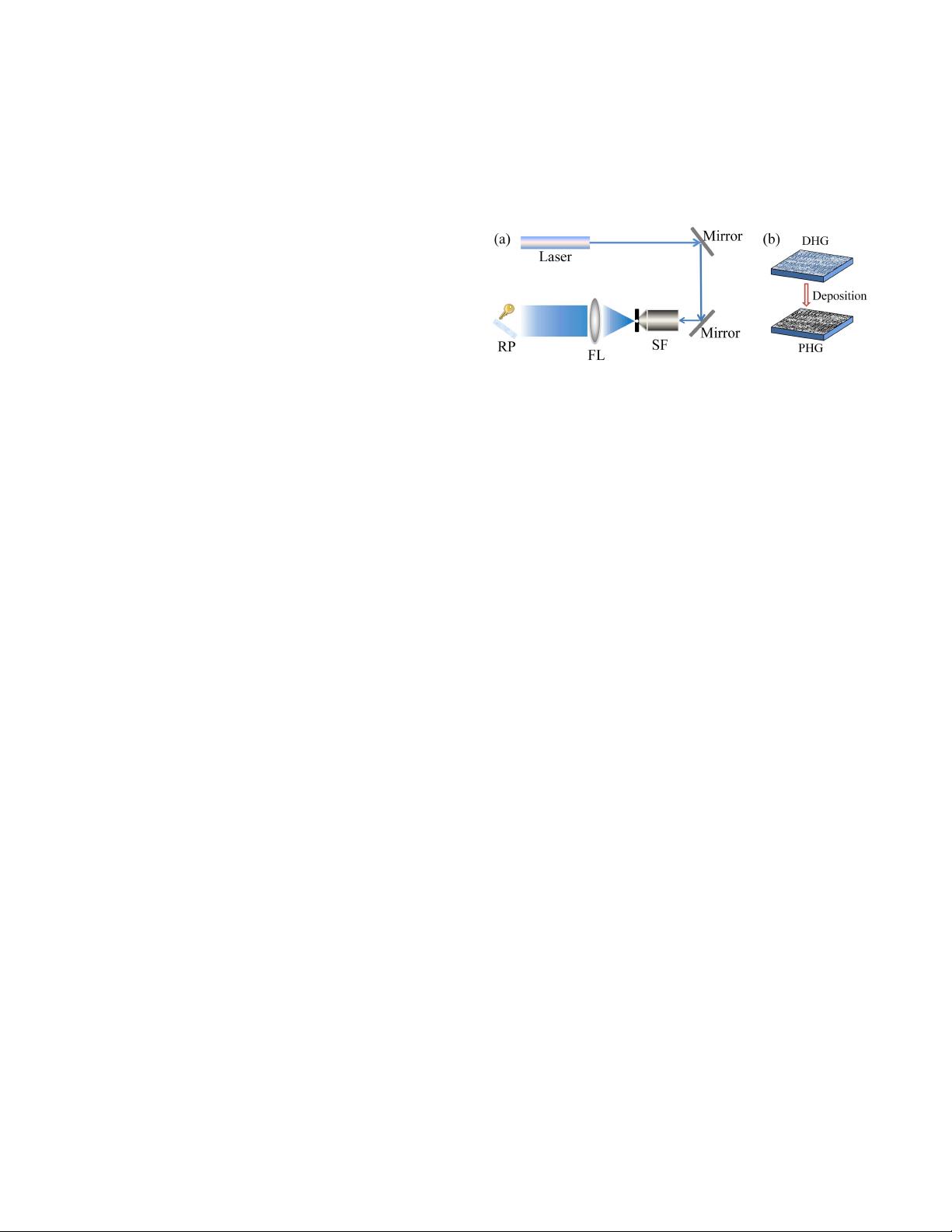

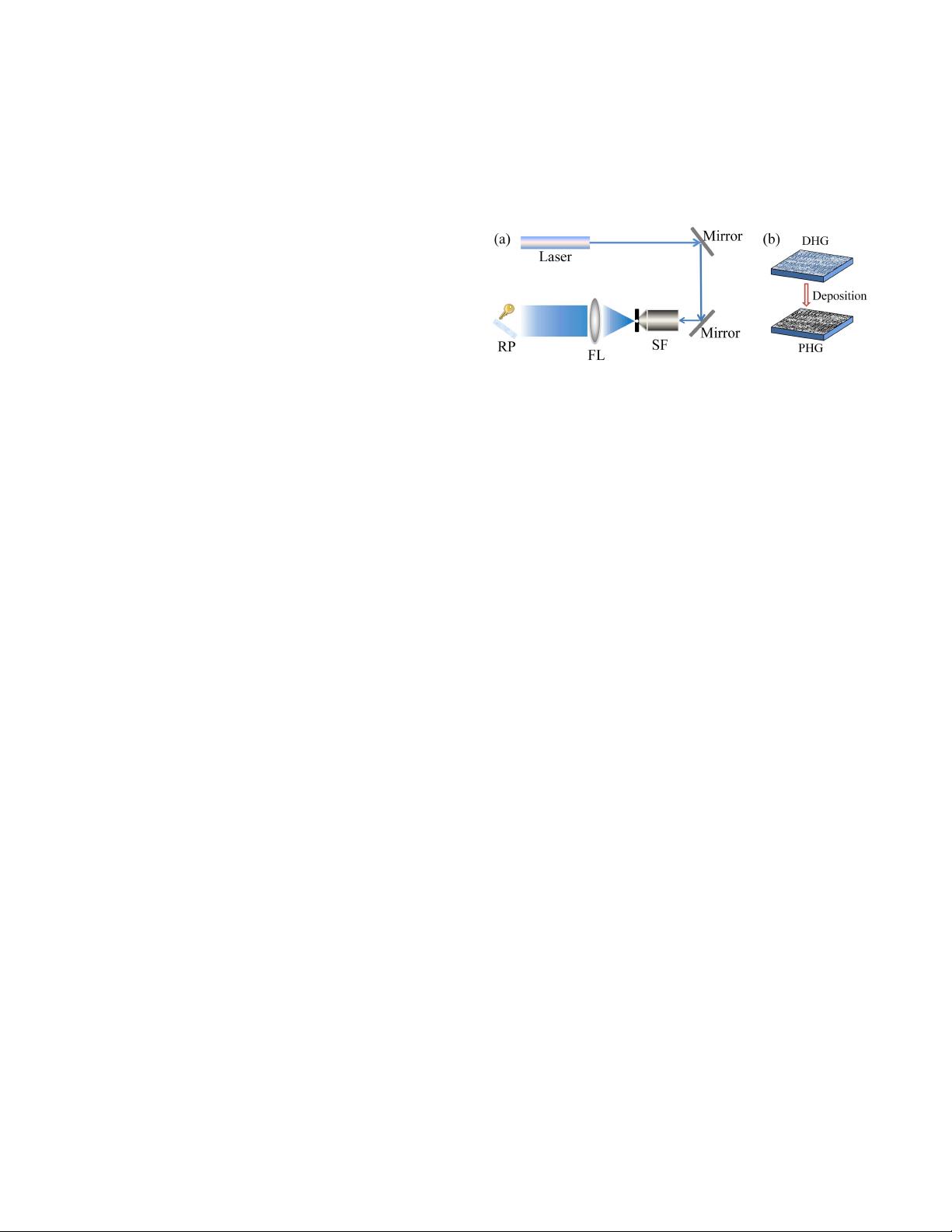

Fig. 1. Fabrication of Plasmonic Hologram: (a) Optical setup for recording

a dielectric hologram. The object to be recorded is set close to the recording

plate to alleviate phase difference blur. RP: recording plate; SF: Spatial Filter;

FL: Focus Lens. (b) Aluminum film of thickness ∼40 nm is deposited onto

the hologram.

Recently, the combination of holography and surface

plasmon [5]–[7] opens a new way to increase the

diffraction efficiency of hologram and realize colored display.

However, the resonance character makes the devices sensitive

to incident angle and wavelength, which makes it hard to

record and reconstruct the hologram [8]. To solve these

problems, we fabricate surface relief hologram at a sub-

wavelength scale by laser interference lithography. Then we

coat the hologram with aluminum to form a periodic metal-

insulator-metal (MIM) structure. Multi-color holographic

images under white light illumination are obtained in broad

viewing angles and wavelengths. Moreover, the new metal

hologram, plasmonic hologram (PHG), exhibits enhancement

of diffraction efficiency and polarization sensitivity without the

need of dichroic or birefringent recording materials [9], [10].

We reveal that the longitudinal surface plasmon modes in the

metal-insulator-metal waveguides (MIMWs) lead to the unique

performances.

II. E

XPERIMENTAL WORK

A. Recording

Figure 1(a) illustrates the setup of hologram recording.

A blue laser beam with wavelength of 457.8 nm (CVI-MG)

is expanded and split into two collimated parts: one directly

reaches the recording plate as the reference light with incident

angle of ∼40°; the other is reflected onto the photoresist by

the object (a key) which is next to the recording plate. The

two laser beams interfere with each other and the interference

fringes are recorded on the photoresist. The average power

intensity of light source is ∼3.8 mW/cm

2

and exposure time is

∼3 minutes. The exposed photoresist is developed with NaOH

(0.7%) for 15-20 seconds. Then, the recording plate is rinsed

with deioned water and heated by hot wind for 30 seconds.

Finally, the photoresist dielectric hologram is obtained.

Subsequently, in Fig. 1(b), a ∼40-nm-thick aluminum

film is deposited onto the hologram using E-beam coater

(ZSX-500D), thus a PHG is obtained. Please note that

1041-1135 © 2015 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission.

See http://www.ieee.org/publications_standards/publications/rights/index.html for more information.