3676 IEEE TRANSACTIONS ON MAGNETICS, VOL. 43, NO. 9, SEPTEMBER 2007

Hard Disk Drive Reliability Modeling and Failure Prediction

Brian D. Strom

1

, SungChang Lee

1

, George W. Tyndall

1

, and Andrei Khurshudov

2

Samsung Information Systems America, San Jose, CA 95134 USA

Seagate Technology, Longmont, CO 80503 USA

A reliability model for the hard disk drive (HDD) is developed, focusing on head–disk separation as the primary independent vari-

able. The model is structured to incorporate the theoretical effects of environmental factors, plus empirical dependence on the product

operating mode. An experimental method based on magnetic spacing loss theory is used to characterize the head–media separation as a

function of temperature, altitude, humidity, and HDD operating mode. A statistical model based on these empirical data is developed to

predict HDD reliability for various operating conditions. The predictions of the model are verified experimentally through comparison

with HDD product reliability test data.

Index Terms—Failure prediction, HDD, head–disk clearance, magnetic hard disk drive, reliability model.

I. I

NTRODUCTION

T

HE hard disk drive (HDD) is a highly complex, mass-pro-

duced, electro-mechanical device that utilizes principles of

magnetic recording for data storage. As fundamental elements

of modern computer systems and consumer electronic devices,

HDDs have managed to combine a steady increase in storage

density and capacity with a concomitant decrease in the cost per

megabyte. The HDD combines the most recent achievements in

the science and technology of magnetic recording, material sci-

ence, and digital signal processing.

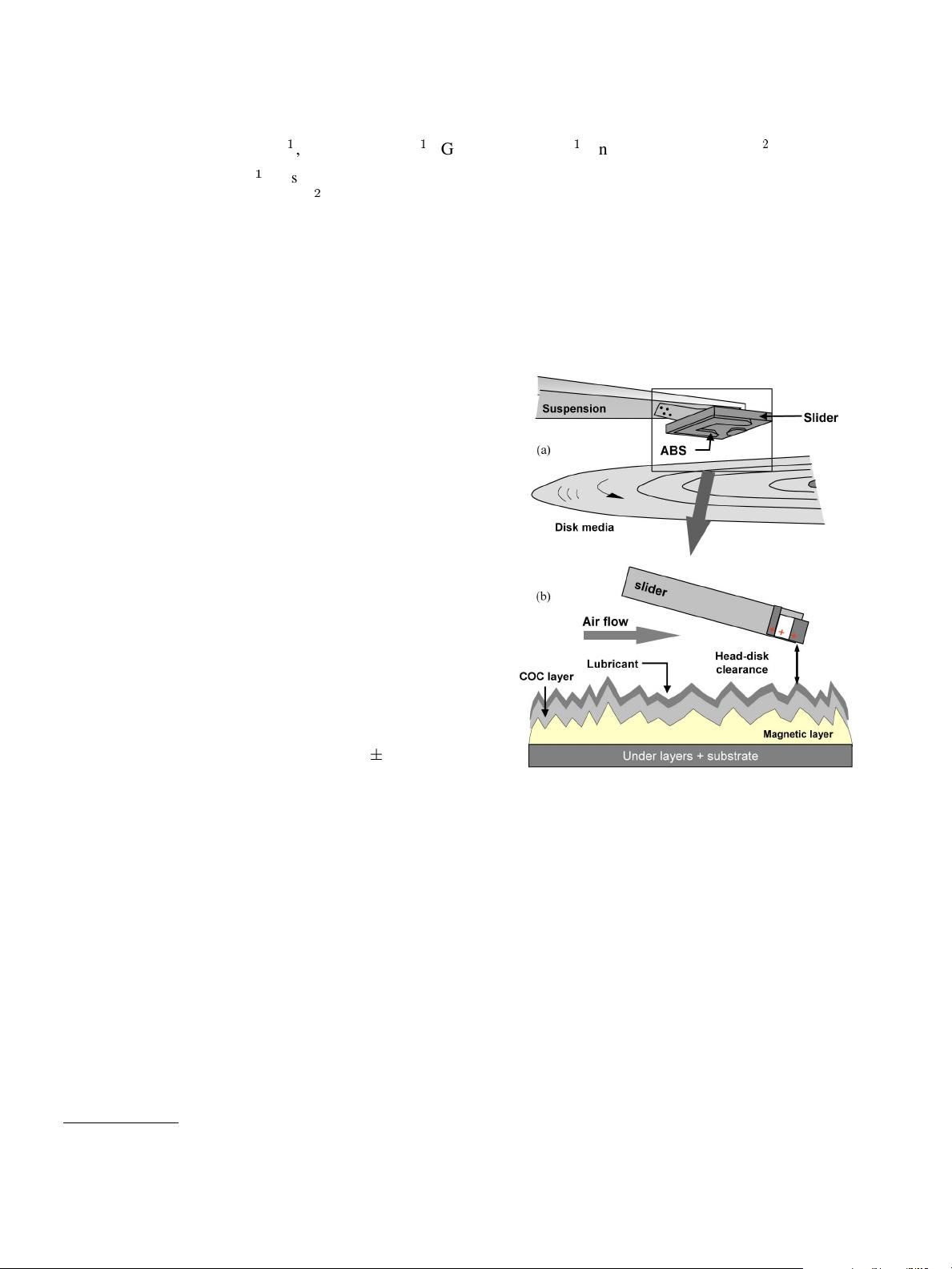

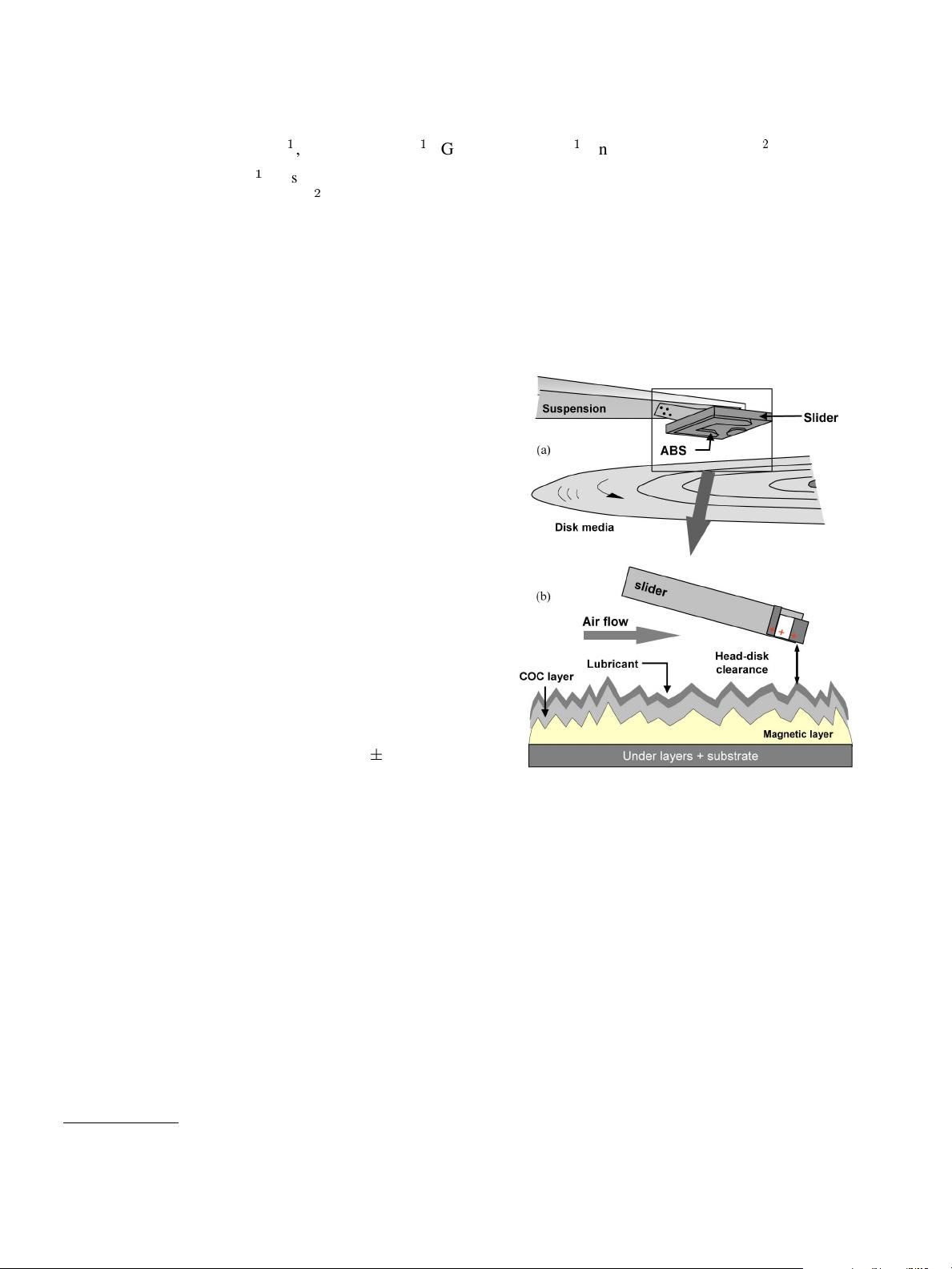

The slider, read/write heads, and magnetic recording media

are the key components of the HDD and form together the

head–disk interface (HDI), illustrated in Fig. 1. These heads are

integrated into the ceramic slider, which includes an air-bearing

surface (ABS) formed in relief on its surface facing the disk

[Fig. 1(a)]. Air entrained between the ABS and disk generates

lift by virtue of the viscous properties of air being squeezed

through the gap. The flow of air is guided by the ABS to control

the head–media spacing within close tolerance (

0.1 nm).

The separation distance between read/write elements and the

disk directly affects both signal strength and resolution, and

is therefore critical to the recording density of the HDD. As

magnetic recording densities increase, the magnetic spacing and

hence the head flying height must decrease correspondingly.

Today, only a few nanometers separate the slider from the disk

surface moving at 30 m/s.

A. Definition of Head–Disk Clearance

We define clearance as the difference between the flying

height (FH) and the glide height avalanche (GHA), which is

the level of highest detected disk asperities. The distribution of

flying height in a slider population is typically normal, charac-

terized by its mean and standard deviation. In a well-designed

interface, the lowest-flying slider of the total population will fly

significantly above the GHA, eliminating the possibility that

Digital Object Identifier 10.1109/TMAG.2007.902969

Color versions of one or more of the figures in this paper are available online

at http://ieeexplore.ieee.org.

Fig. 1. Schematic diagrams of the head–disk interface. (a) The slider contains

the read/write heads and is positioned on the disk by its suspension. The slider

also includes the air-bearing surface (ABS) facing the disk. (b) The slider in side

view, flying over a cross section of the disk surface (roughness exaggerated).

Recording transducers write to and read from the disk magnetic layer, while

carbon overcoat (COC), lubricant layers, and surface roughness limit how close

to the disk the recording elements can fly.

any heads drag on the disk at high speed. Fig. 2(A) illustrates

such a condition for an exemplary product operating at room

temperature: it has mean clearance 5.3 nm and standard devia-

tion 0.8 nm, thus operating at a 6-sigma level ensuring positive

clearance.

The demand for HDD products with higher areal densities,

coupled with the cost pressures of a mass-production environ-

ment where inspection of all incoming components is not prac-

tical, can result in HDD product populations having some finite

“interference” of the FH distribution with the GHA. This inter-

ference can be exacerbated by the environmental conditions in

which the HDD is operated. In Fig. 2(B), we illustrate the case

of “minor interference” where the tail of the flying height dis-

tribution overlaps the disk GHA level. Fig. 2(c) shows the case

0018-9464/$25.00 © 2007 IEEE