162 IEEE TRANSACTIONS ON SEMICONDUCTOR MANUFACTURING, VOL. 28, NO. 2, MAY 2015

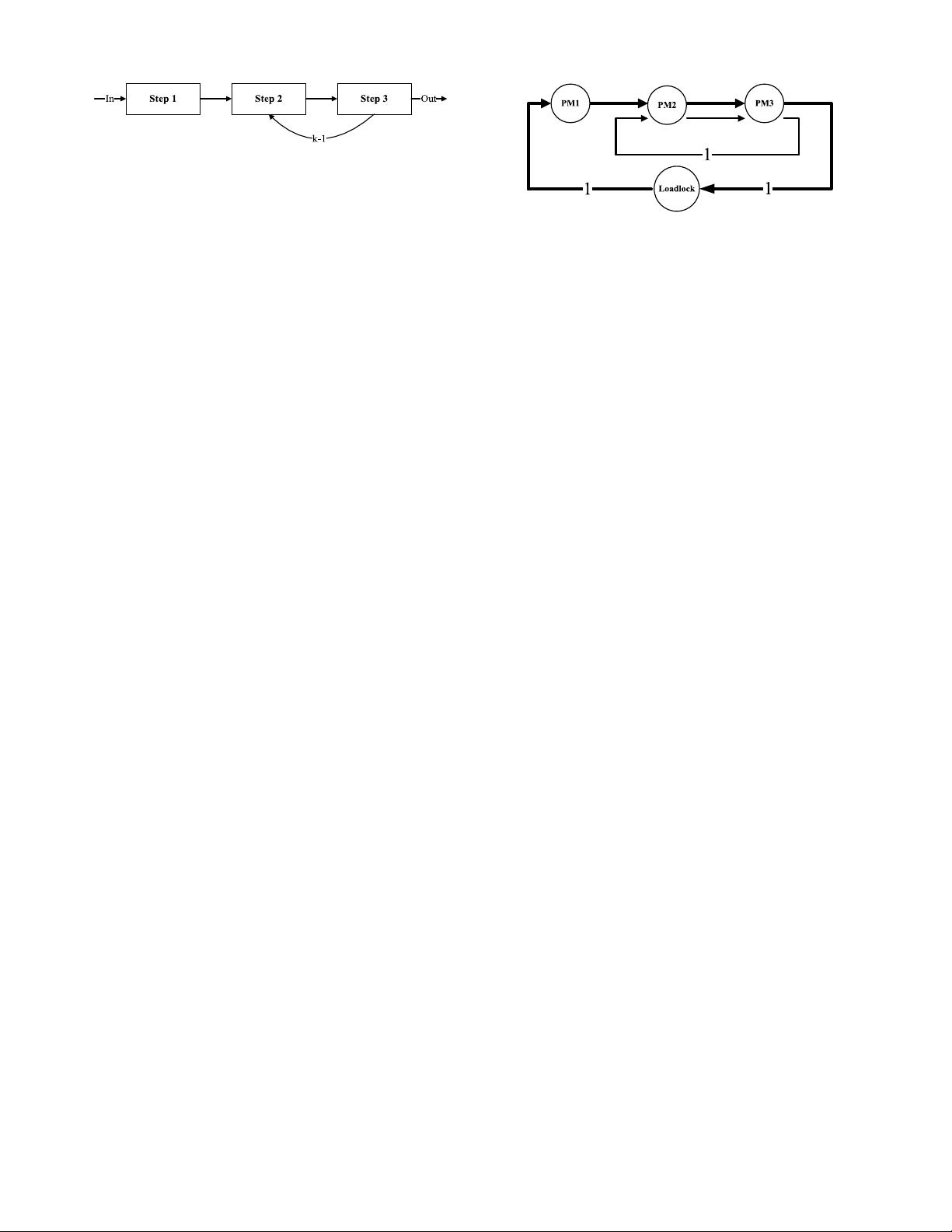

Fig. 2. Wafer flow for ALD process.

is typical and thus considered as an example in this paper.

For an ALD process, the thickness of the deposition layer is

determined by the number of revisiting times [15]. In an ALD

process, there are three steps, and a wafer visits Step 1 once,

and then Steps 2 and 3 for k ≥ 2 times as shown in Fig. 2,

where k is determined by a process plan. Let d

i

be the number

of PMs for Step i, then the wafer flow pattern for ALD can

be denoted as (d

1

,(d

2

, d

3

)

k

) with (d

2

, d

3

)

k

being the revis-

iting process. Often, when a wafer revisits a step it requires

exactly the same processing environment as it previously vis-

its this step. Consequently, each step is composed of only

one PM, or d

1

= d

2

= d

3

= 1. Then, it is assumed that

PM

1

,PM

2

, and PM

3

are used to process wafers at Steps 1–3,

respectively. Thus, the wafer flow pattern of an ALD process

can be denoted as (PM

1

,(PM

2

, PM

3

)

k

) with (PM

2

, PM

3

)

k

being a k-revisiting process. Without loss of generality and

to make the paper easy to follow, we assume that k = 2,

i.e., (PM

1

,(PM

2

, PM

3

)

2

).

B. Activity Description

There are several processing steps in a cluster tool for wafer

fabrication. The LLs can also be seen as a wafer processing

step. Hence, we treat the LLs as Step 0. According to [29], in

operating a cluster tool, PM activities follow the robot tasks.

Thus, it is critically important to schedule robot activities.

They include unloading a wafer from a PM, moving from

a PM to another with a wafer carried, loading a wafer into

a PM, moving from a PM to another without carrying a wafer,

and waiting. The key is to schedule the robot activities given

the tool’s status and process requirements. We use u

i

and l

i

to denote the robot unloading and loading a wafer from and

into PM

i

, i ∈ N

3

= {1, 2, 3}, respectively. As mentioned in

Section I, a swap strategy is efficient for scheduling dual-arm

cluster tools. A swap operation at PM

i

is executed as follows:

the robot holds a wafer in one arm → unloads a processed

wafer from PM

i

by the other arm → the robot rotates → loads

arawwaferintoPM

i

. In this way, a swap operation at PM

i

is

completed. It follows from this process that l

i

and u

i

together

with a rotation form a swap operation at Step i, i ∈ N

3

, and

we use s

i

to denote it. We use m

ij

to denote the robot mov-

ing from Steps i to j. In this paper, Steps 2 and 3 together

form a revisiting process. Therefore, m

32

represents the robot

moving from Steps 3 to 2.

For the purpose of scheduling, the temporal aspect for each

activity is necessary. The time taken for unloading a wafer is

denoted as α. Similarly, the time taken for loading a wafer

into a PM and moving from a PM to another are denoted as

β and μ, respectively. Although a swap operation includes

unloading and loading, the time taken for a swap operation is

not simply their sum. We use λ to denote its time. Besides

the robot activities, we use a

i

to denote the wafer processing

time at Step i, i ∈ N

3

.

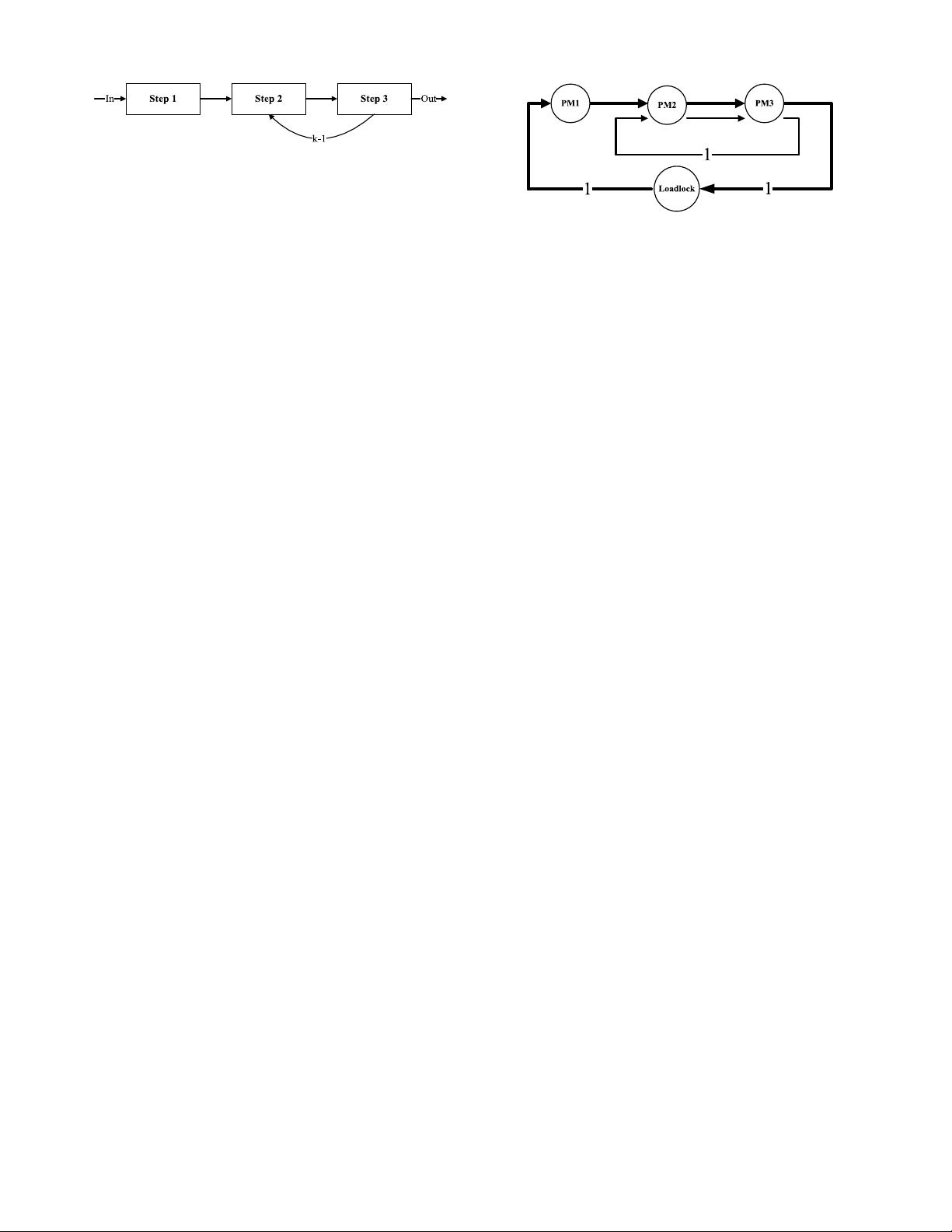

Fig. 3. Wafer flow process by using one-wafer schedule.

C. One Wafer Scheduling Strategy

Let us recall how to obtain an optimal periodic schedule

for the k = 2 case. We use m

ij

to denote robot moving from

PM

i

to PM

j

.Letl

0

and u

0

denote robot’s loading and unload-

ing a wafer into and from an LL, respectively. In the revisiting

process (PM

2

, PM

3

)

2

, robot’s task sequence σ

1

=swapping

at PM

3

→ m

32

→ swapping at PM

2

→ m

23

forms a cycle

and it is called a local cycle. Sequence σ

2

=swapping at

PM

3

→ m

30

→ l

0

→ u

0

→ m

01

→ swapping at PM

1

→

m

12

→ swapping at PM

2

→ m

23

forms a cycle involving

all PMs once and it is a global cycle. A one-wafer schedule

should contain one local and one global cycle as shown in

Fig. 3. It is optimal in terms of cycle time according to [23].

Let M = {S

1

, S

2

, S

3

, S

4

} denote a state of the system,

where S

i

= {W

d

(q)}, i ∈ N

3

, and W

d

(q)isthed-th wafer

released to the system with its q-th operation being processed

in PM

i

(Step i). S

4

= {R

j

(W

d

(q)} represents the d-th wafer

held by the robot with its q-th operation to be processed at

Step j, j ∈ N

3

. For an optimal one-wafer steady-state sched-

ule, according to [23], the tool should start from state M

i

= {W

3

(1), W

1

(2), W

2

(3), R

1

(W

4

(1))} which is called the

first desired steady state. At this state, the 3rd, 1st and 2nd

wafers are being processed in PM

1

, PM

2

, and PM

3

for their

1st, 4th, and 3rd operations, respectively. At the same time, the

robot holds the 4th wafer with the 1st operation to be processed

at Step 1. From this state, by performing σ

3

=swapping

at PM

1

→ m

12

→ swapping at PM

2

→ m

23

, the system

enters state M

i+1

= {W

4

(1), W

3

(2), W

2

(3), R

3

(W

1

(5))}. Then,

by executing σ

1

, it reaches M

i+2

= {W

4

(1), W

2

(4), W

1

(5),

R

3

(W

3

(3))}. Finally, by executing σ

4

=swapping at PM

3

→

m

30

→ l

0

→ u

0

→ m

01

, M

i+3

= {W

4

(1), W

2

(4), W

3

(3),

R

1

(W

5

(1))} is reached. Notice that σ

3

and σ

4

together form

a global cycle, and M

i

and M

i+3

are equivalent. Therefore,

a period including a local and a global cycle is formed. During

this period, one wafer is unloaded from the LLs, while another

is completed and returns to the LLs.

Next, we analyze how the system can optimally enter the

first desired steady state from the idle state.

III. S

TART-UP TRANSIENT PROCESS SCHEDULING

In order to schedule the transient process from the idle state

to the required steady state, the program evaluation and review

technique (PERT) is applied based on network techniques.

By PERT, a network model is used to describe graphically the

precedence relationships of the activities in a project. Such

a network model is called a PERT model. The PERT has been

used in scheduling transient processes of a cluster tool [6].