658 IEEE TRANSACTIONS ON INTELLIGENT TRANSPORTATION SYSTEMS, VOL. 13, NO. 2, JUNE 2012

As has been discussed in a previous section, objects might

be partially obscured due to occlusions or range failures. For

example, when a car is only partially observed on one side, if

we do not assume any strong model on the car or we do not

even know that the object is a car, an estimation of its size and

center point could be quite unreliable. Partial observation could

greatly affect the reliability of feature parameter estimation and

could subsequently reduce accuracy in tracking moving objects.

Developing an object model to support robust feature parameter

extraction on partial observation data is key to this procedure,

as well as for building a tracking module.

In addition, a desirable detection result is that all moving

objects be successfully detected with a minimal number of false

alarms. When a moving object enters the area of laser coverage,

software can easily find the object as long as it gives a reflection

to the laser beam. However, because an object might be simul-

taneously measured by different laser scanners and because the

contour points of an object might be spatially disconnected due

to occlusions or range failures, multiple alarms could arise from

a single moving object. To reduce multiple alarms and have

more complete knowledge for feature parameter estimation,

developing an algorithm of grouping the measurements from

different laser scanners into the same object is another key to

this procedure.

In the succeeding sections, we define an object model, we

address a method of grouping the measurements from different

laser scanners to detect moving objects in the environment

and extract their feature parameters, and we conclude with an

experimental result that verifies the algorithm.

A. Object Model

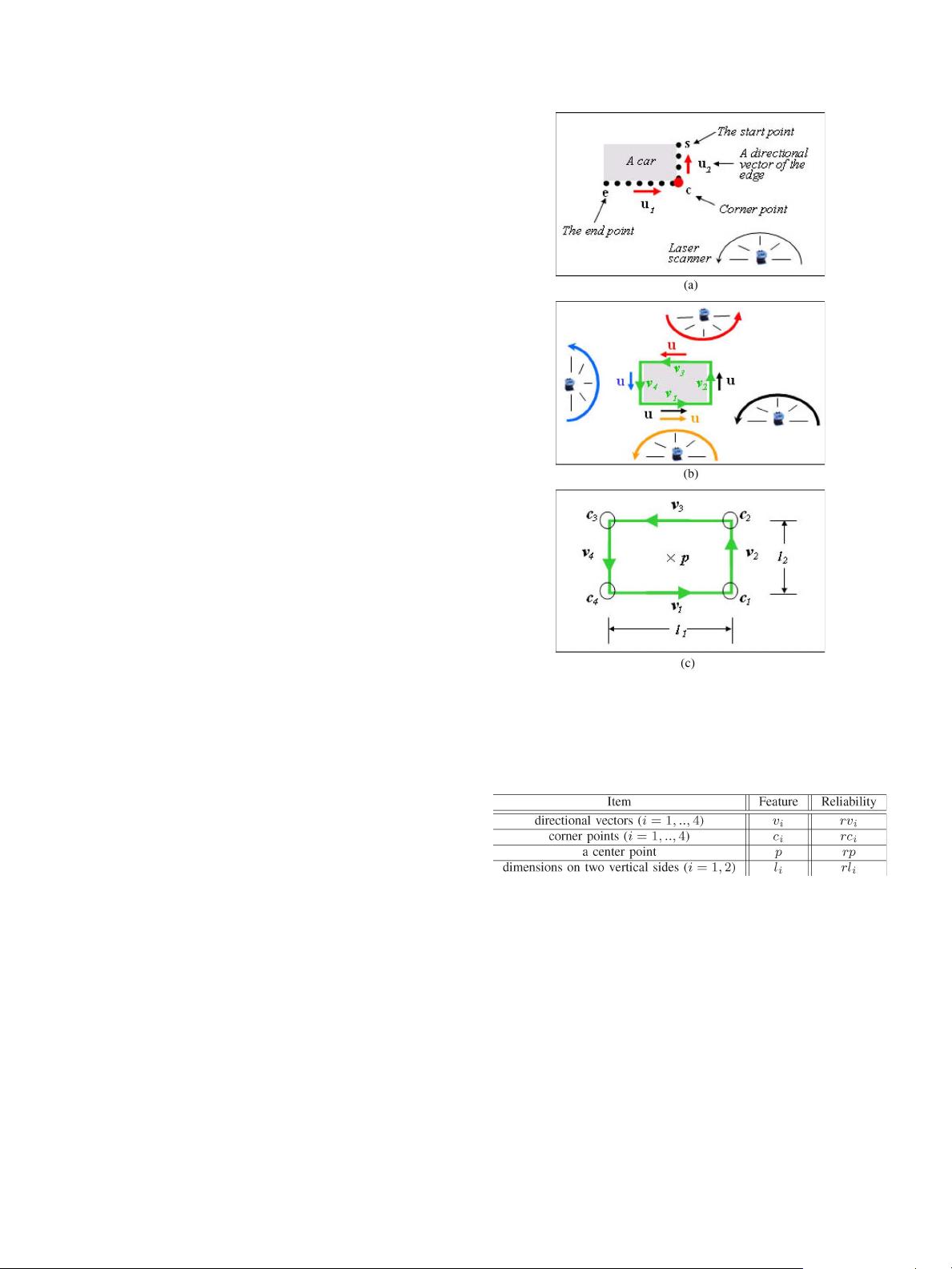

Fig. 5 describes a special characteristic of laser measure-

ments. Suppose that a laser scanner performs counterclockwise

scanning, and the horizontal contour of a car is measured by a

sequence of laser points from s to e [see Fig. 5(a)]. Simplifying

the shape of a car using a rectangle, edges that represent two

vertical sides of the car can be detected through a corner

detector and a line fitting on the laser points. A directional

vector u

i

that is associated with each edge is defined according

to the scanning order of laser points, e.g., from a point measured

later to one measured earlier.

Let u denote a directional vector that is extracted from the

data of a single laser scanner after its alignment to a reference

frame. We found that no matter where a laser scanner is placed,

directional vectors u are equal if they are observations on the

same side of the object [see Fig. 5(b)]. Suppose that v

i

s, i =

1,...,4arethedirectional vectors defined on each side of a

car, and they compose a counterclockwise loop. By matching u

with v

i

s, we can find which side of the object is measured so

that the laser points that correspond to u are used to update the

estimates of that specific side. In this work, we call u a support

vector of the side v

i

.

Based on t he aforementioned considerations, an object model

is defined in this work with the feature parameters shown in

Fig. 5(c), where the shape of an object is simplified using a

rectangular model. Developing a more accurate model for each

kind of object will be addressed in future work. In addition,

Fig. 5. Definition to an object model. (a) Measurement to a car from a single

laser scanner. (b) Measurements to a car from a network of laser scanners.

(c) Feature parameters of the object model.

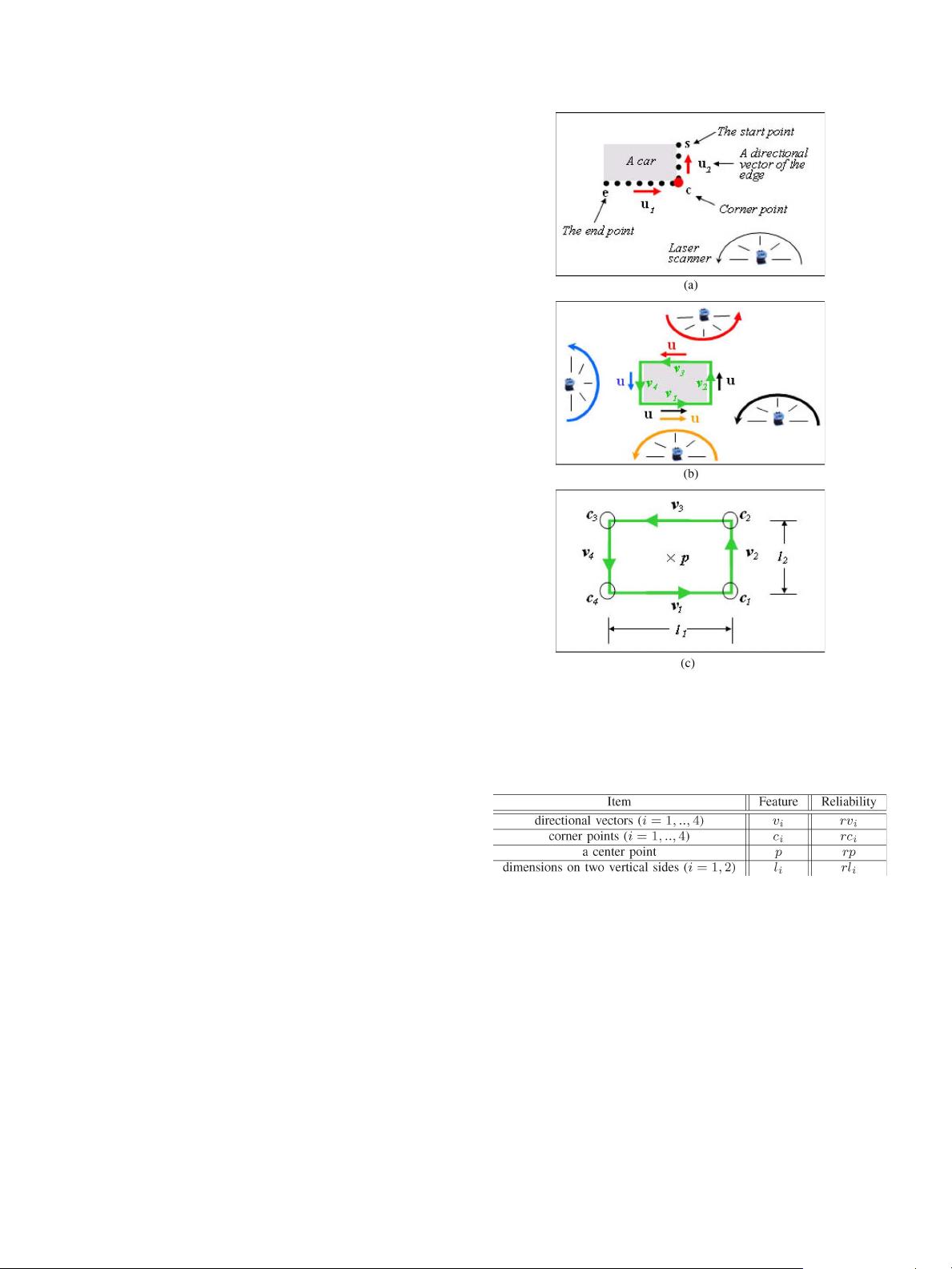

TABLE I

P

ARAMETERS IN AN OBJECT MODEL

a reliability item is defined for each feature parameter for the

sake of partial observations (see Table I). Currently, reliabilities

are estimated with binary values, i.e., true =1or false =0.In

the case of a directional vector, the reliability denotes whether

the side has a support vector (reliable)ornot(unreliable).

In the case of a corner point, if both neighboring sides are

supported, the corner point is a (reliable) one; otherwise, it is

a guess through other feature parameters on the object model

(unreliable). In the case of dimensional size, reliability tells

whether the corresponding feature parameter represents a full

dimensional size (reliable) or perhaps a partial one (unreliable).

In the case of a center point, which cannot be directly observed,

the reliability denotes whether the coordinates are estimated

from other reliable feature parameters. A more detailed de-

scription of each parameter in an object model can be found

in Appendix A.