8

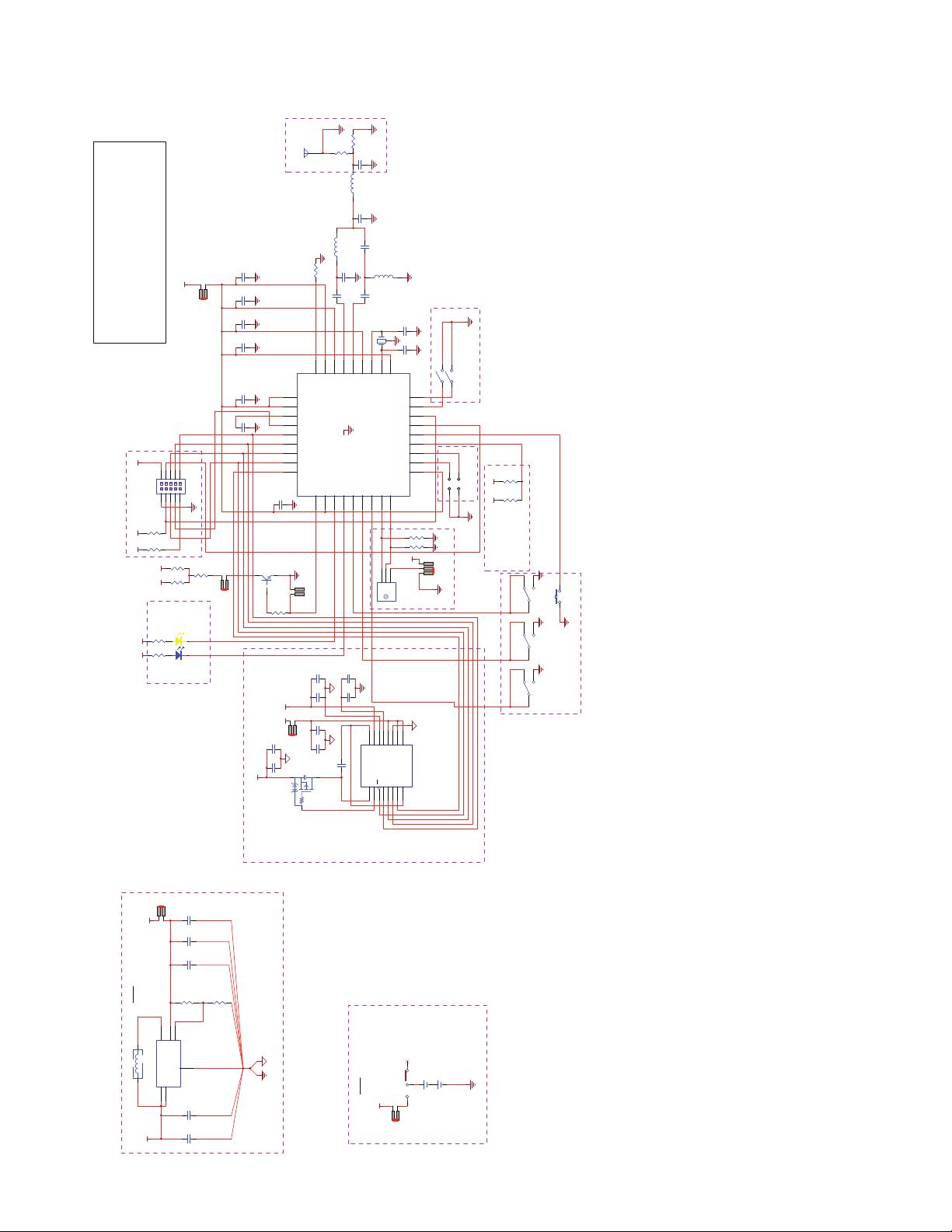

LASER Drive

Oscalator

ADNS-9800

Image

VCSEL

NCS

SCLK

MOSI

MISO

MOTION

XYLASER

LASER_NEN

+VCSEL

-VCSEL

PWR_OPT

DGND

VDDIO

REFA

VDD 3/REFB

GND

VDD 5/VDD 3

Power and control

Serial Port and Register

Figure 7. Block diagram of ADNS-9800

Regulatory Requirements

• Passes FCC B and worldwide analogous emission limits

when assembled into a mouse with shielded cable and

following PixArt recommendations.

• Passes IEC-1000-4-3 radiated susceptibility level when

assembled into a mouse with shielded cable and

following PixArt recommendations.

• Passes EN61000-4-4/IEC801-4 EFT tests when

assembled into a mouse with shielded cable and

following PixArt recommendations.

• Provides sufficient ESD creepage/clearance distance to

withstand discharge up to 15 KV when assembled into

a mouse according to usage instructions above.

• Passes IEC/EN 60825-1 Eye Safety Class 1 when

operating with the laser output power pre-calibrated

by PixArt Imaging without external hardware and

software control of laser current.

Parameter Symbol Min. Max. Units Notes

Laser

output

power

LOP

716

mW

Class 1 limit with

ADNS-6190-002

lens.

Design Considerations for Improving ESD Performance

For improved electrostatic discharge performance, typical

creepage and clearance distance are shown in the table

below. Assumption: base plate construction as per the

PixArt supplied 3D model file when use with ADNS-6190-

002 lens. The lens flange can be sealed (i.e. glued) to the

base plate. Note that the lens material is polycarbonate

and therefore, cyanoacrylate based adhesives or other

adhesives that may damage the lens should NOT be used.

Eye Safety

The ADNS-9800 sensor and the associated components in

the schematics of Figure 6 are intended to comply with

Class 1 Eye Safety Requirements of IEC 60825-1. PixArt

Imaging calibrates the sensor’s laser output power

(LOP) to Class 1 eye safety level and store the registers

values that control the LOP prior shipping out, thus no

LOP calibration is required in complete mouse system at

manufacturer site.

ADNS-9800 sensor is designed to maintain the laser

output power using ADNS-6190-002 lens within Class 1

Eye Safety requirements over components manufactur-

ing tolerances under the recommended operating con-

ditions and application circuits of Figure 6 as specified in

this document. Under normal operating conditions, the

sensor generates the drive current for the VCSEL. Increas-

ing the LOP by other means on hardware and software

can result in a violation of the Class 1 eye safety limit of

716 mW. For more information, please refer to Eye Safety

Application Note.

LASER Drive Mode

The laser is driven in pulsed mode during normal

operation. A calibration mode is provided which drives the

laser in continuous (CW) operation for testing purpose.

The default setting of laser is in Forced_Disable mode,

which the laser is turned OFF. The laser have to be turned

ON during power up sequence by setting Forced_

Disabled bit (Bit-0) of LASER_CTRL0 register to 0.

Disabling the LASER

LASER_NEN is connected to the gate of an external

P-channel MOSFET transistor which, when ON connects

REFB to the laser. In normal operation, LASER_NEN is low.

In the case of a fault condition, LASER_NEN goes high to

turn the transistor off and disconnect REFB from the laser.

ADNS-9800 Laser Gaming Sensor

All rights strictly reserved any portion in this paper shall not be reproduced, copied or transformed to any other forms without permission.

PixArt Imaging Inc.

E-mail: fae_service@pixart.com.tw

Typical Distance (mm) ADNS-6190-002

Creepage 17.3

Clearance 1.8