《PFMEA-失效模式分析案例.pdf:过程项目潜在严重失效的预防和控制策略》

13 浏览量

更新于2024-03-21

收藏 545KB PDF 举报

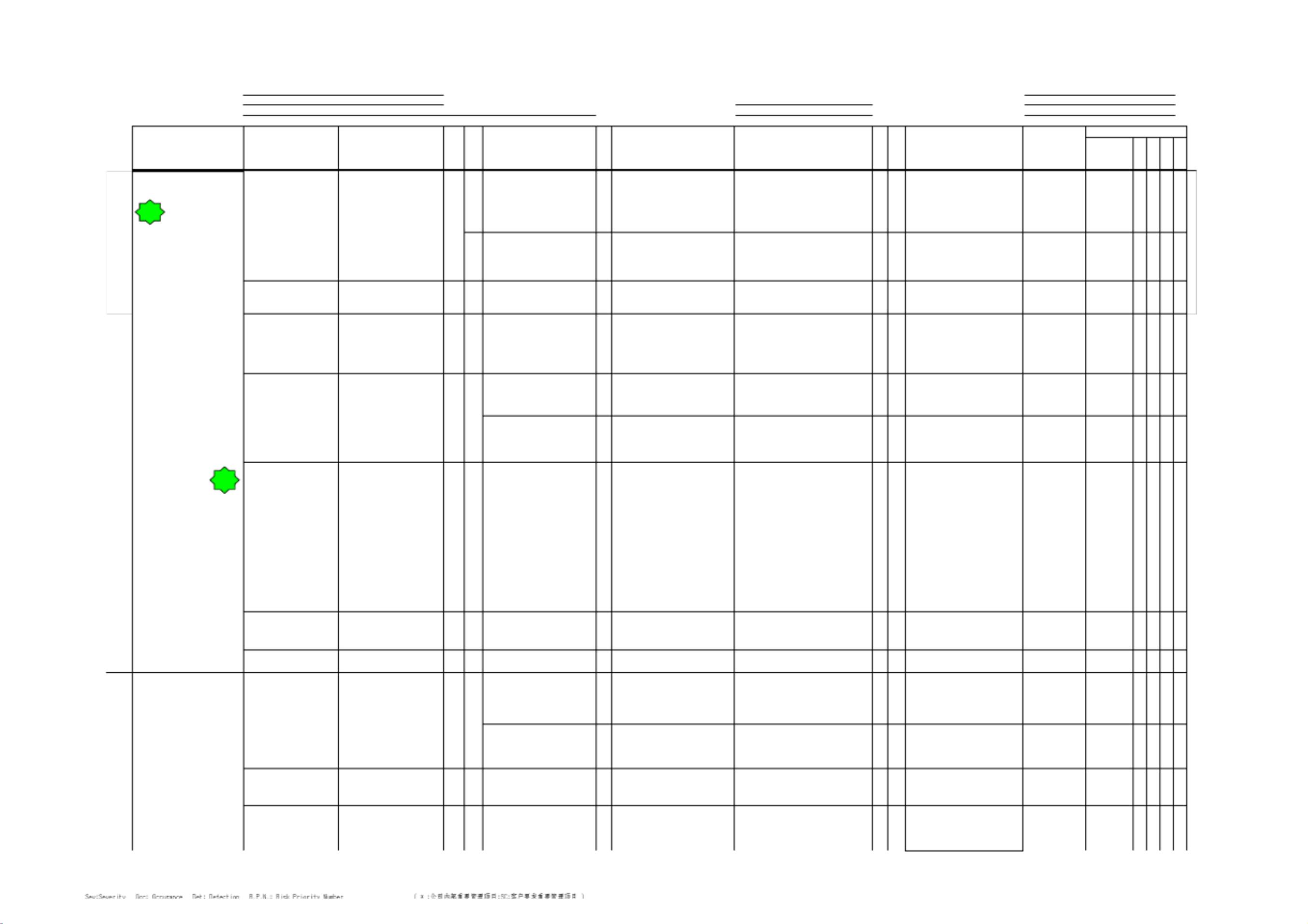

The Process Failure Mode and Effects Analysis (PFMEA) is a systematic method for identifying potential failure modes in a process, determining their impact on the overall system, and developing preventive and control measures to reduce risks. In the case study provided in the document "PFMEA-失效模式分析案例.pdf," the focus is on a specific project within a company, where the core team is responsible for preparing and implementing the PFMEA.

The document outlines the potential failure modes, severity, and frequency of occurrence for various process steps, along with the current preventive and control measures in place. It also highlights recommended actions to address the identified risks and improve the process. The responsibility for implementing these actions and verifying their effectiveness is clearly defined, along with key target dates for completion.

Through the PFMEA analysis, the company aims to enhance the quality of its products, reduce the likelihood of defects, and optimize the efficiency of its operations. By proactively addressing potential failure modes and implementing preventive measures, the company can avoid costly mistakes, improve customer satisfaction, and maintain a competitive edge in the market.

In conclusion, the PFMEA process is an essential tool for organizations to systematically assess and mitigate risks in their processes, ultimately leading to improved performance and higher standards of quality. This case study serves as a practical example of how the PFMEA methodology can be applied in a real-world business setting to drive continuous improvement and achieve operational excellence.

2020-07-10 上传

2024-07-25 上传

2013-04-11 上传

2024-11-10 上传

2023-05-14 上传

2024-11-02 上传

2024-11-02 上传

2024-11-10 上传

2023-02-06 上传

是空空呀

- 粉丝: 197

- 资源: 3万+

最新资源

- Python-Assignment

- recipe-website:详细的海绵蛋糕食谱

- 控制性心律失常v2

- RedHook2:PC上的Red Dead Redemption II的开源脚本挂钩

- LinkedList-in-Java:该程序实现了完整的链表集合

- Konecty:Konecty开源技术业务平台

- pokefront:用Vue2制作的前端,使用PokeAPI作为后端

- struts2urlplugin:Struts2 插件支持 URL 中的模式匹配,用于动作映射器

- blockbuster:在线租借的电影和影集商店

- 06-08-module2projects-elsiempk:GitHub Classroom创建的06-08-module2projects-elsiempk

- Selenium测试

- MovieBooking:这是使用香草javascript开发的电影嘘声屏幕

- sila-postman-signer:轻量级本地服务器,用于使用ECDSA签署请求并将请求转发到所需的主机。 包括与此服务器一起使用的Sila API的Postman集合

- SquareGridViewDemo:一个GridView, Items是正方形

- java中高级笔记整合.rar

- JMS:用于高性能计算的工作流管理系统和基于Web的群集前端