IEEE JOURNAL OF SOLID-STATE CIRCUITS, VOL. 54, NO. 12, DECEMBER 2019 3257

A Fast Startup CMOS Crystal Oscillator

Using Two-Step Injection

Karim M. Megawer , Student Member, IEEE, Nilanjan Pal, Student Member, IEEE,

Ahmed Elkholy , Member, IEEE, Mostafa Gamal Ahmed , Student Member, IEEE,

Amr Khashaba , Student Member, IEEE, Danielle Griffith, Member, IEEE,

and Pavan Kumar Hanumolu, Member, IEEE

Abstract—Fast startup crystal oscillators (XOs) are needed

in heavily duty-cycled communication systems for implementing

aggressive dynamic power management schemes. This article

presents the ways to improve startup time of XOs. Using a two-

step injection technique in a three-step process, the proposed

technique reduces the XO startup time to within 1.5× the theo-

retical minimum. By solving the differential equation governing

crystal resonator under injection for arbitrary injection fre-

quency, the behavior of energy build-up inside a crystal resonator

is analyzed and used to determine optimum injection time as a

function of the desired XO steady-state amplitude and injection

frequency error. Bounds on tolerable injection frequency error

to guarantee the existence of optimal timing are provided.

Fabricated in a 65-nm CMOS process, the proposed 54-MHz fast

startup XO occupies an active area of 0.075 mm

2

and achieves

a startup time of less than 20 µs across a temperature range of

− 40

◦

Cto85

◦

C while consuming a startup energy of 34.9 nJ

and operating from a 1.0-V supply.

Index Terms— Crystal oscillator (XO), digitally controlled

oscillator (DCO), injection, ring oscillator (RO), startup time.

I. INTRODUCT ION

C

RYSTAL oscillators (XOs) are at the h eart of almost

all communication systems. They are used to perform

key time keeping functions and provide precise and accurate

clocks needed in high-frequency synthesis in all wireless

systems. To reduce average power consumption, such systems

are heavily duty-cycled by turning on for a very small duration

of time and turning off for the most part [1]–[3]. In such

scenarios, long startup time of XOs (T

START

) limits the efficacy

of duty-cycling as it limits the minimum turn on duration [3].

In othe r words, while the high-quality factor of crystals is

beneficial in achieving excellent frequency stability, it becomes

a major bottleneck in reducing the average power of heavily

Manuscript received April 25, 2019; revised July 13, 2019 and

August 11, 2019; accepted August 12, 2019. Date of publication

September 10, 2019; date of current version November 22, 2019. This article

was approved by Guest Editor Youngcheol Chae. (Corresponding author:

Karim M. Megawer.)

K. M. Megawer, N. Pal, M. G. Ahmed, A. Khashaba, and P. K. Hanumolu

are with the Department of Electrical and Computer Engineering, Uni-

versity of Illinois at Urbana–Champaign, Urbana, IL 61801 USA (e-mail:

megawer2@illinois.edu).

A. Elkholy is with Broadcom, Irvine, CA 92620 USA.

D. Griffith is with Texas Instruments Incorporated, Dallas, TX 75243 USA.

Color versions of one or more of the figures in this article are available

online at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/JSSC.2019.2936296

duty-cycled systems. Therefore, the focus of this article is on

reducing the startup time of XOs.

Many attempts have already been made to reduce T

START

.

Such efforts can be broadly classified into three categories that

rely on: 1) choosing crystal resonator parameters that favor

smaller T

START

; 2) increasing XO amp litude growth rate; and

3) increasing initial noise energy inside the crystal resonator

at startup. While it is possible to choose a crystal resonator

with parameters that reduce T

START

, such choices always have

a detrimental impact on steady-state XO performance. For

example, a crystal with smaller lo ad capacitance will result in

smaller T

START

but increases frequency sensitivity to environ-

mental conditions, and a crystal with lower quality factor will

have a smaller T

START

at the expense of degraded frequency

stability and phase noise. In view of these conflicting tradeoffs,

most of the recent work h as been focused on improving

T

START

by using methods that do not directly depend on crystal

resonator parameters.

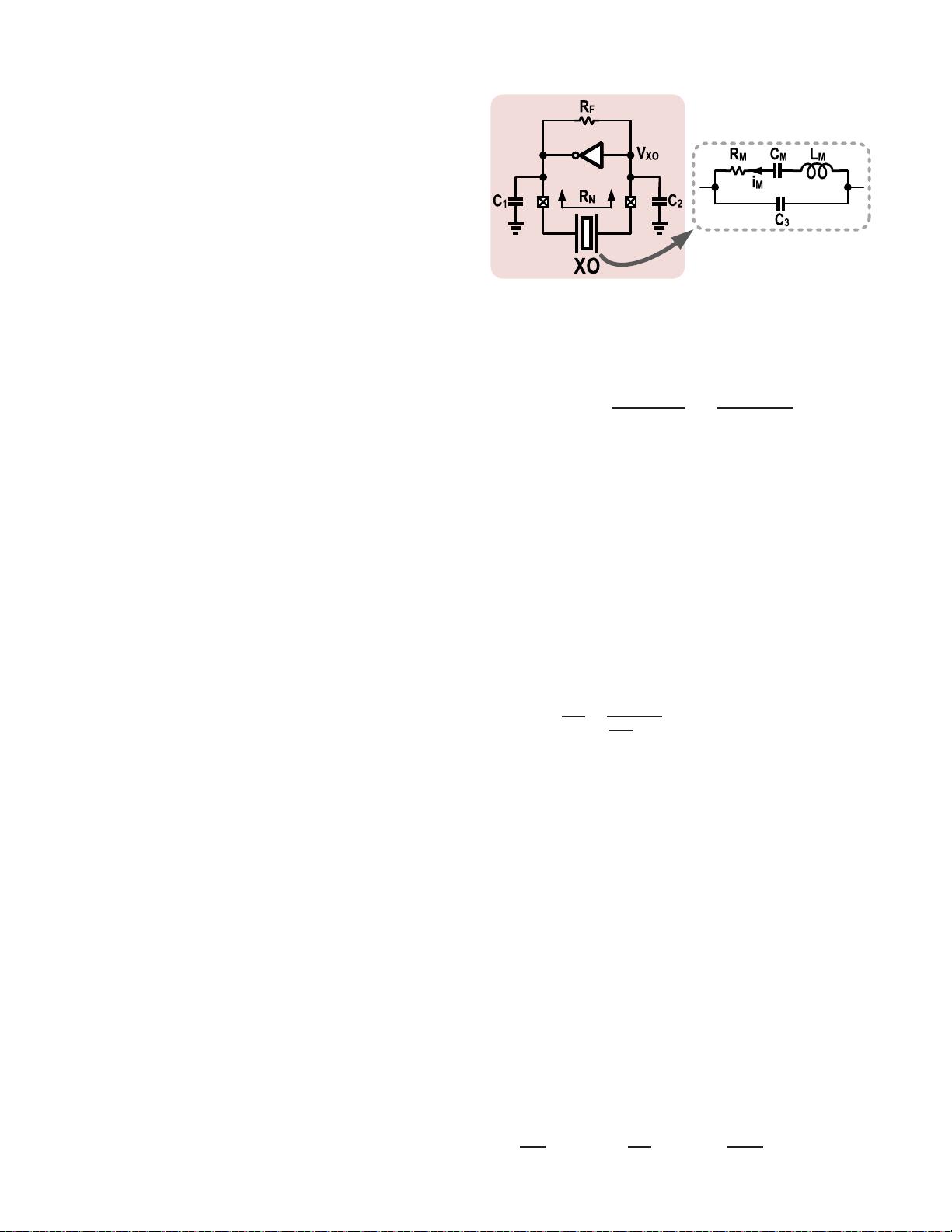

For a given crystal resonator, T

START

can be reduced

by increasing XO amplitude growth rate via increasing the

negative resistance (R

N

) seen from the XO [4]–[7] by:

1) increasing the XO transconductance using multiple XO

cores connected in parallel [4]; 2 ) temporarily increasing

XO core current during startup [5]; 3) reducing startup load

capacitance using dynamically adjusted load [5]; or 4) can-

celing crystal resonator parasitic capacitance with inductive

impedance using dual-mode three-stage g

m

scheme [6] or

by adding a zero in R

N

transfer function using multistage

amplifier with feed forward path [7]. Due to the linear depen-

dence of R

N

on transconductance in [4], the existence of

parasitic capacitances in [5], settling time overhead during

switching between modes in [6], and the dependence on initial

noise seed in [7], these techniques show limited improvement

compared with techniques that employ increasing the initial

noise amplitude by injecting a surge of energy into the crystal

resonator at startup.

It has been shown that injecting energy into the crystal at

exactly the resonator frequency until the current in the res-

onator reaches its steady-state value (i

M,SS

) results in theoret-

ical m inimum startup time [4] (in some applications, oscillator

output can be used even before this time). However, matching

injection frequency to within few 100 ppm of the resonator

frequency poses a serious practical challenge in achieving

0018-9200 © 2019 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission.

See http://www.ieee.org/publications_standards/publications/rights/index.html for more information.