Introduction

2

the semiconductor device and magnetic components. In the continuous effort to decrease

the volume of power converters, the switching frequency is becoming higher, and the

power density of converters is higher. The increasing use of surface-mount technology,

avoidance of fans to reduce noise and volume, and reduced package dimensions all

intensify the thermal design requirement.

At the present time, the design practice in power supply industry is that both EMI

and thermal requirements are tested at the final hardware implementation stage. A long

redesign time is normally necessary if corrections are needed. A more efficient way to

deal with these two issues is to tackle them in the design process, before the hardware

implementation is done. It’s the primary objective of this thesis to develop a methodology

to deal with the issues and demonstrate the feasibility in a practical power circuit. With

these tools, not only design time can be greatly reduced but also extrapolation of

performance can be easily made for design optimization.

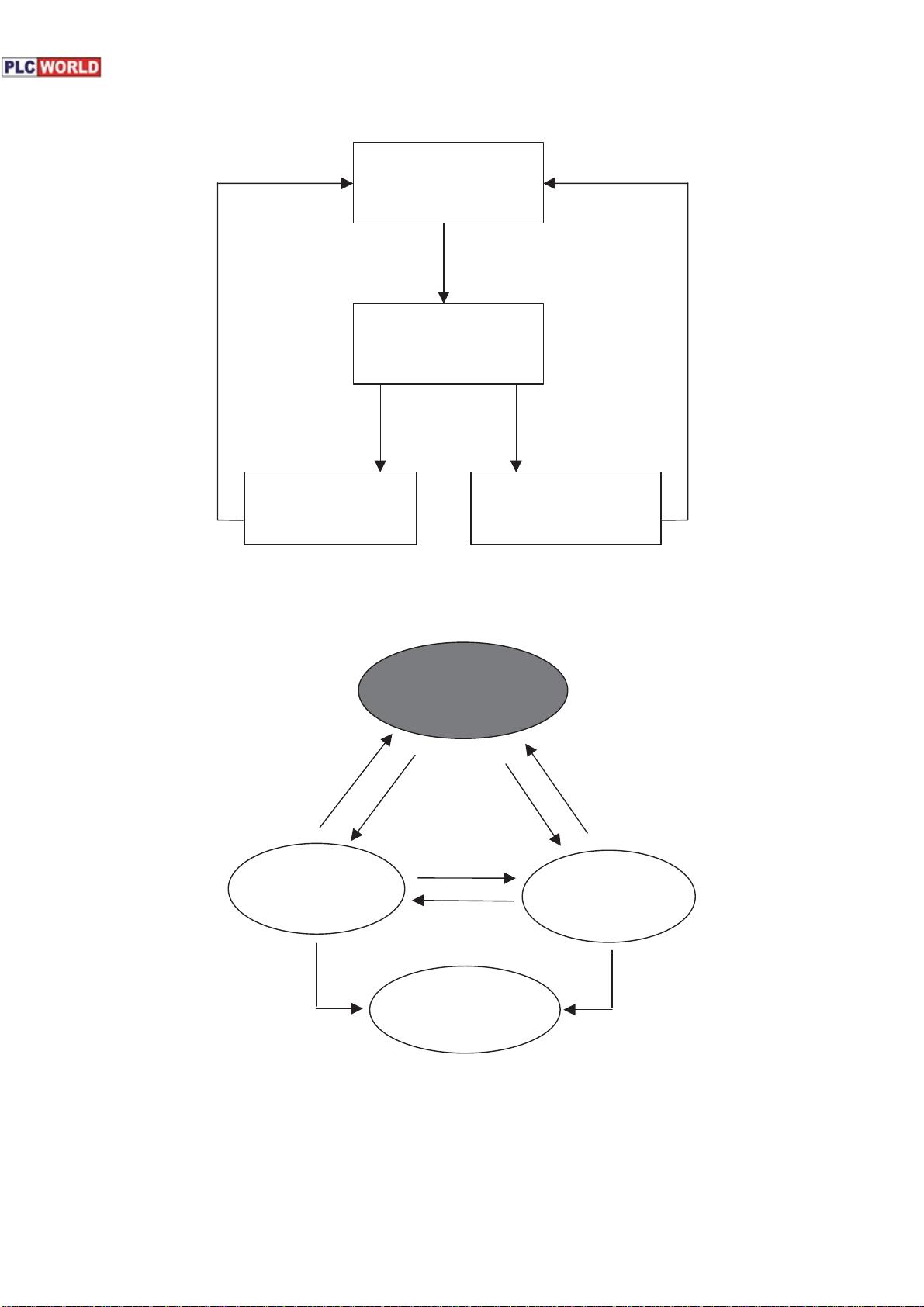

1.2. Approach

The approach used in this thesis is based on four existing simulation tools, the

InCa, a parasitic parameter extracting software, the Ansoft, a Maxwell electromagnetic

field simulation and parameter extraction tool, the Saber, a circuit simulation tool, and

the Flotherm, a thermal analysis tool. These will be discussed in the following.

Conducted EMI simulation

Parasitic elements play major roles in the EMI performance of a power supply.

Therefore, all the essential parasitic elements of the power circuit and the printed circuit

board must be included to perform EMI simulation. For the discrete components such as

MOSFETs and diodes, the parasitic elements can be found from the product manual. For

the input and output capacitors, the parasitic elements can be measured by an Impedance

Analyzer. The parasitic elements of magnetic component can be analytically calculated or

practically measured. And the software InCa is used to extract the layout parasitic

elements and generate an equivalent circuit. Both the power circuit and the layout

equivalent circuit are then connected for EMI performance simulation. Software Saber is

then used to simulate the circuit.

Thermal simulation

www.plcworld.cn