C

7/01

TNY253/254/255

4

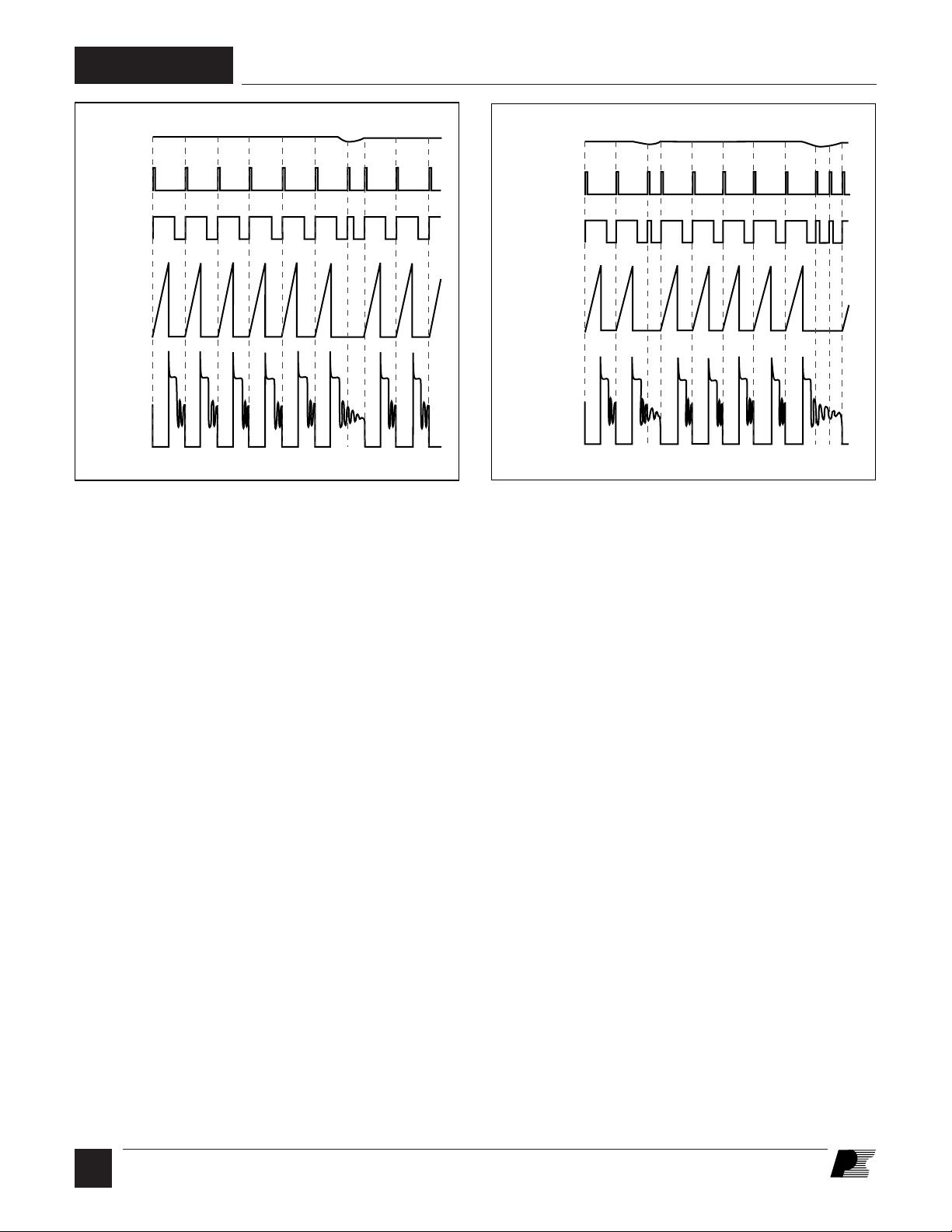

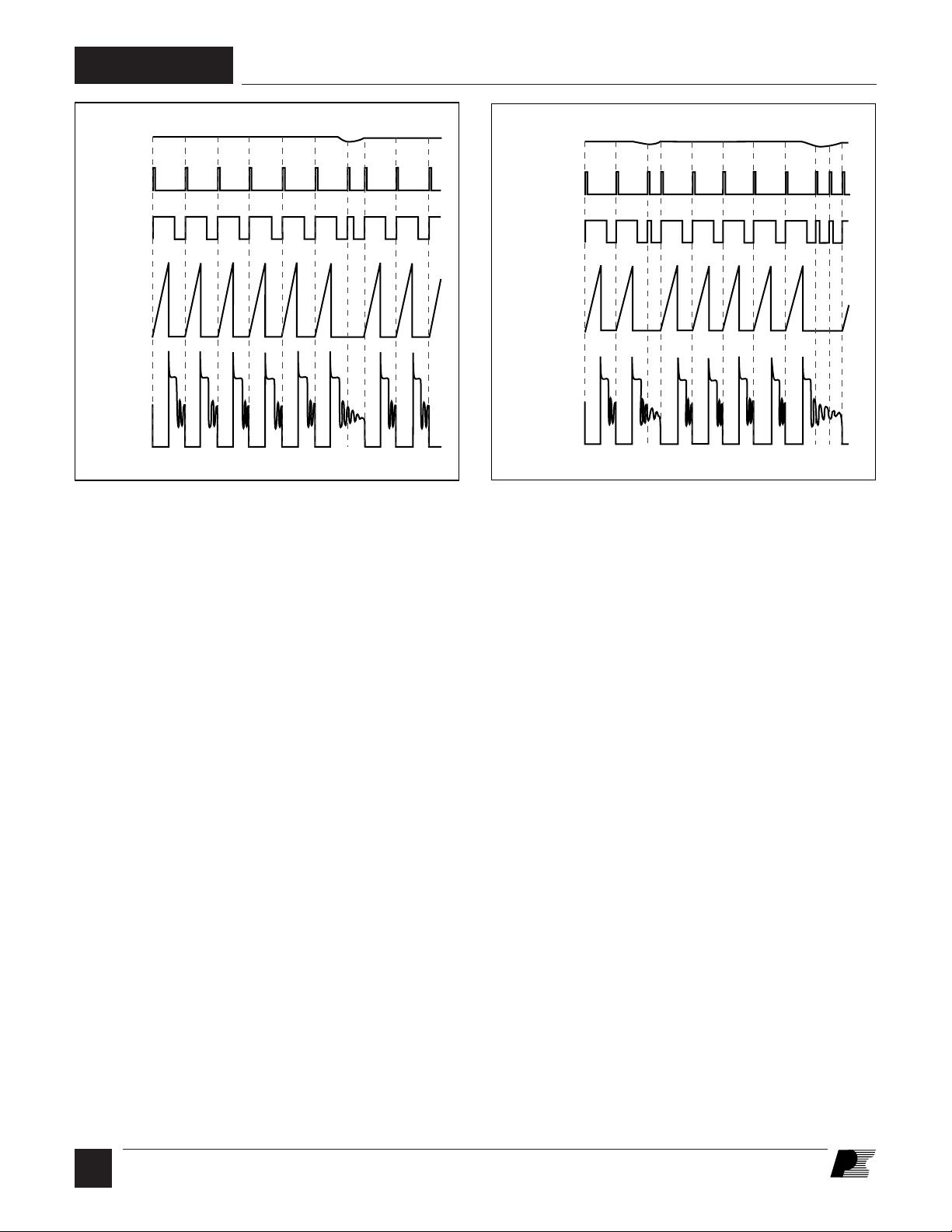

Figure 4. TinySwitch Operation at Heavy Load. Figure 5. TinySwitch Operation at Medium Load.

V

DRAIN

V

EN

CLOCK

DC

DRAIN

I

MAX

PI-2255-061298

V

DRAIN

V

EN

CLOCK

DC

DRAIN

I

MAX

PI-2259-061298

percentage of cycles will conduct to support the power

consumption of the power supply.

The response time of TinySwitch ON/OFF control scheme is

very fast compared to normal PWM control. This provides high

line ripple rejection and excellent transient response.

Power Up/Down

TinySwitch requires only a 0.1 µF capacitor on the BYPASS

pin. Because of the small size of this capacitor, the power-up

delay is kept to an absolute minimum, typically 0.3 ms (Figure7).

Due to the fast nature of the ON/OFF feedback, there is no

overshoot at the power supply output. During power-down, the

power MOSFET will switch until the rectified line voltage

drops to approximately 12 V. The power MOSFET will then

remain off without any glitches (Figure 8).

Bias Winding Eliminated

TinySwitch does not require a bias winding to provide power to

the chip. Instead it draws the power directly from the DRAIN

pin (see Functional Description above). This has two main

benefits. First for a nominal application, this eliminates the cost

of an extra bias winding and associated components. Secondly,

for charger applications, the current-voltage characteristic often

allows the output voltage to fall to low values while still

delivering power. This type of application normally requires a

forward-bias winding which has many more associated

components, none of which are necessary with TinySwitch.

Current Limit Operation

Each switching cycle is terminated when the DRAIN current

reaches the current limit of the TinySwitch. For a given primary

inductance and input voltage, the duty cycle is constant.

However, duty cycle does change inversely with the input

voltage providing “voltage feed-forward” advantages: good

line ripple rejection and relatively constant power delivery

independent of the input voltage.

44 kHz Switching Frequency (TNY253/254)

Switching frequency (with no cycle skipping) is set at 44kHz.

This provides several advantages. At higher switching

frequencies, the capacitive switching losses are a significant

proportion of the power losses in a power supply. At higher

frequencies, the preferred snubbing schemes are RCD or diode-

Zener clamps. However, due to the lower switching frequency

of TinySwitch , it is possible to use a simple RC snubber (and

even just a capacitor alone in 115VAC applications at powers

levels below 4W).

Secondly, a low switching frequency also reduces EMI filtering

requirements. At 44kHz, the first, second and third harmonics

are all below 150kHz where the EMI limits are not very

restrictive. For power levels below 4W it is possible to meet

worldwide EMI requirements with only resistive and capacitive

filter elements (no inductors or chokes). This significantly

reduces EMI filter costs.

Finally, if the application requires stringent noise emissions

(such as video applications), then the TNY253/254 will allow

more effective use of diode snubbing (and other secondary

snubbing techniques). The lower switching frequency allows

RC snubbers to be used to reduce noise, without significantly

impacting the efficiency of the supply.