"基于PLC的C650车床控制系统设计"

版权申诉

108 浏览量

更新于2024-02-25

收藏 1.38MB DOCX 举报

Control System of The C650 Lathe Design Based on PLC

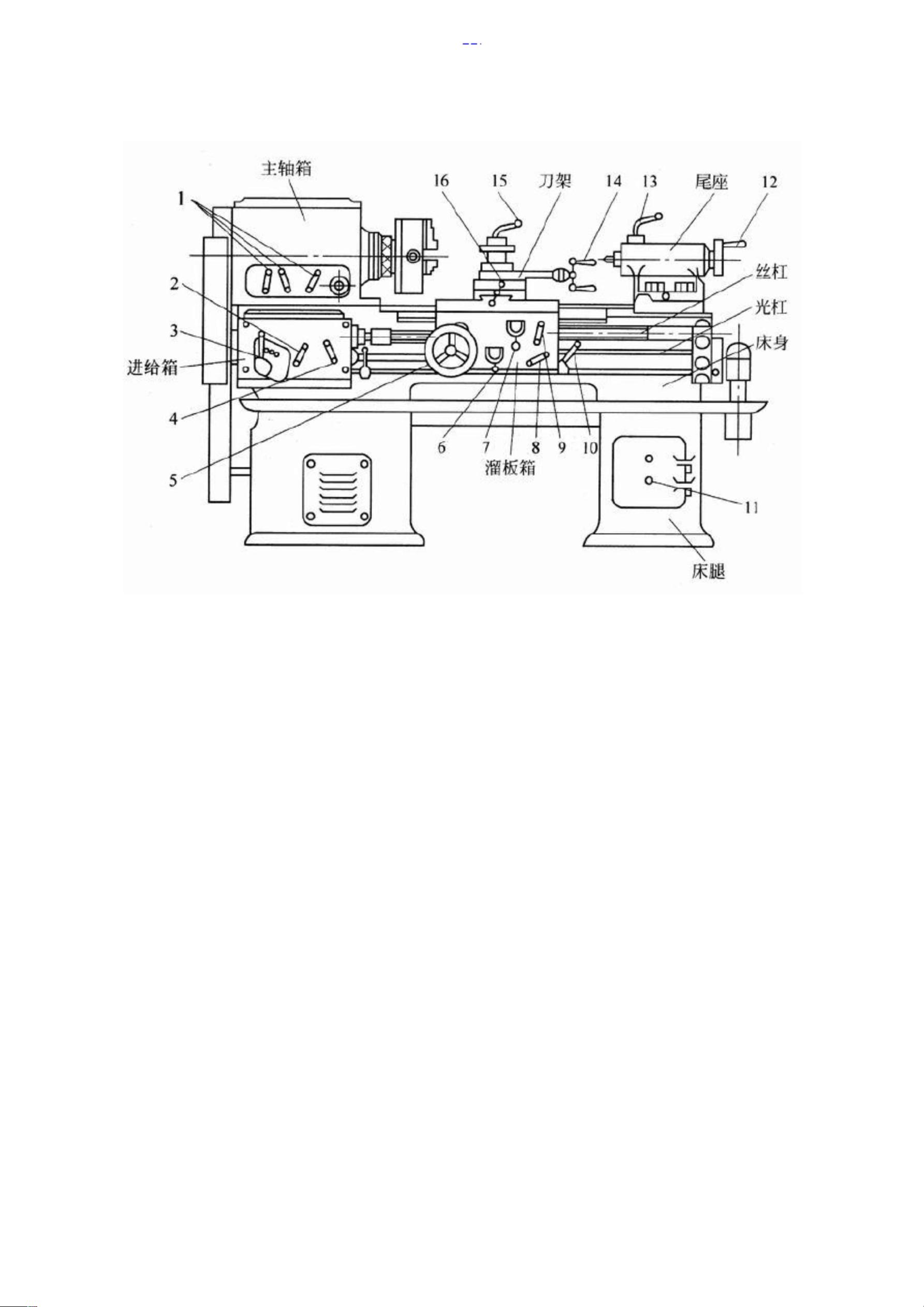

In response to the issues of frequent malfunctions, complicated maintenance, and outdated electrical systems in traditional turning lathes, this paper proposes a new approach to improving the control system of the C650 lathe using Programmable Logic Controller (PLC) technology. Through analysis of the electrical principles and control requirements of the lathe, this design aims to address the challenges faced by the outdated control systems and align them with the requirements of modern industrial production.

The design takes into consideration factors such as the number of I/O points required for control, the cost-effectiveness of performance, the implementation and optimization of various control functions. The main processes involved in this design include analysis of the electrical principles of the lathe, selection of control components, allocation of I/O points in the PLC, and ladder diagram programming for the control system.

Compared to traditional control systems, PLC control systems offer advantages such as simplified hardware wiring, lower functional consumption, faster response times, stable operation, and enhanced capabilities. By replacing the original control system of the lathe with a PLC system, the lathe can be more easily adapted to changing control requirements and, with the appropriate programming, can also achieve automated machining functions.

The key words for this design include C650 horizontal lathe, electrical control principles, S7-200 PLC, and ladder diagram. The integration of PLC technology in the control system of the C650 lathe offers a more efficient, reliable, and versatile solution for modern industrial production requirements.

2022-07-12 上传

2022-07-11 上传

2021-10-13 上传

2021-09-18 上传

2022-04-04 上传

2022-12-01 上传

2021-10-01 上传

2024-07-02 上传

xxpr_ybgg

- 粉丝: 6788

- 资源: 3万+

最新资源

- JavaScript实现的高效pomodoro时钟教程

- CMake 3.25.3版本发布:程序员必备构建工具

- 直流无刷电机控制技术项目源码集合

- Ak Kamal电子安全客户端加载器-CRX插件介绍

- 揭露流氓软件:月息背后的秘密

- 京东自动抢购茅台脚本指南:如何设置eid与fp参数

- 动态格式化Matlab轴刻度标签 - ticklabelformat实用教程

- DSTUHack2021后端接口与Go语言实现解析

- CMake 3.25.2版本Linux软件包发布

- Node.js网络数据抓取技术深入解析

- QRSorteios-crx扩展:优化税务文件扫描流程

- 掌握JavaScript中的算法技巧

- Rails+React打造MF员工租房解决方案

- Utsanjan:自学成才的UI/UX设计师与技术博客作者

- CMake 3.25.2版本发布,支持Windows x86_64架构

- AR_RENTAL平台:HTML技术在增强现实领域的应用