Introduction

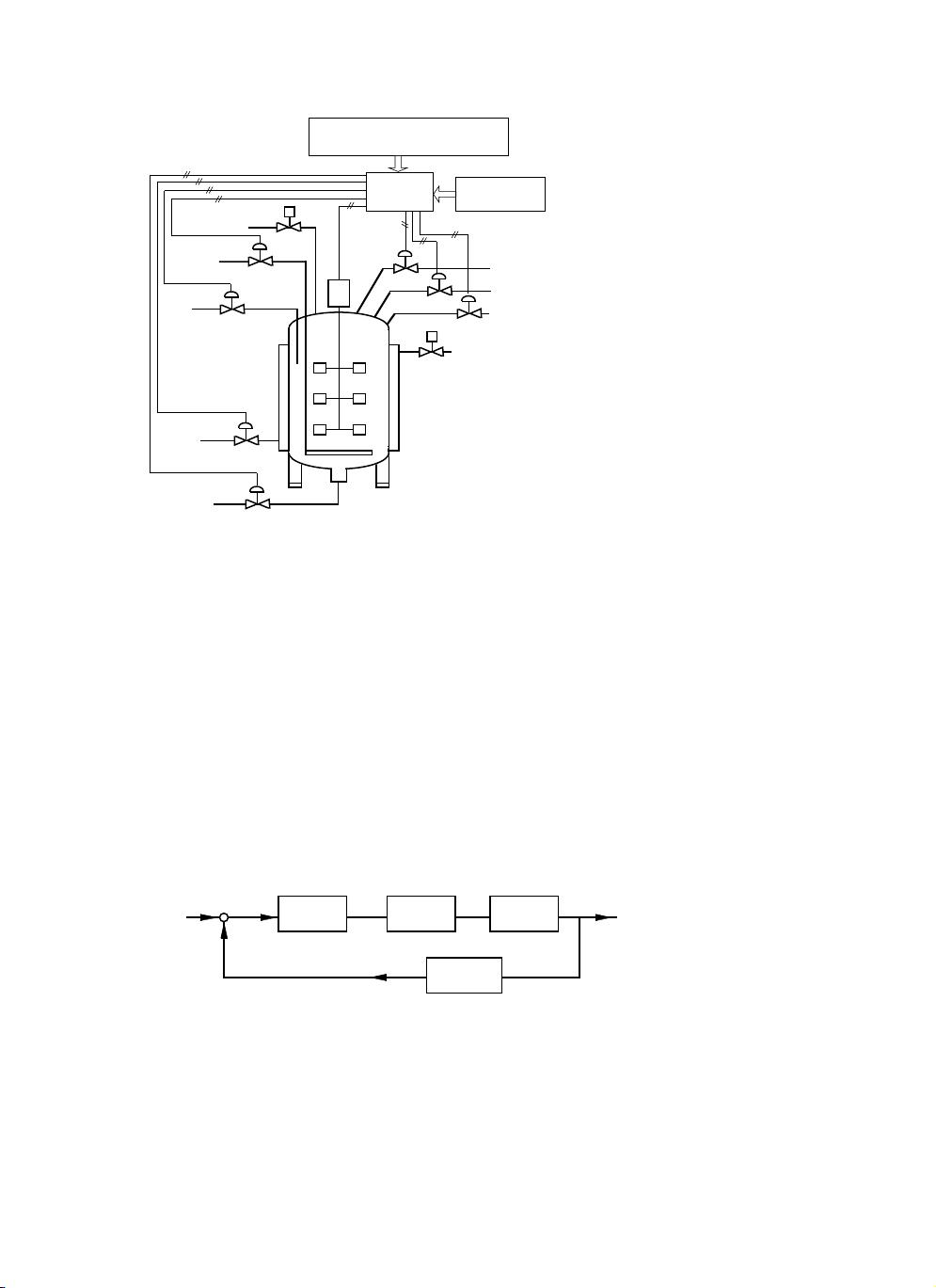

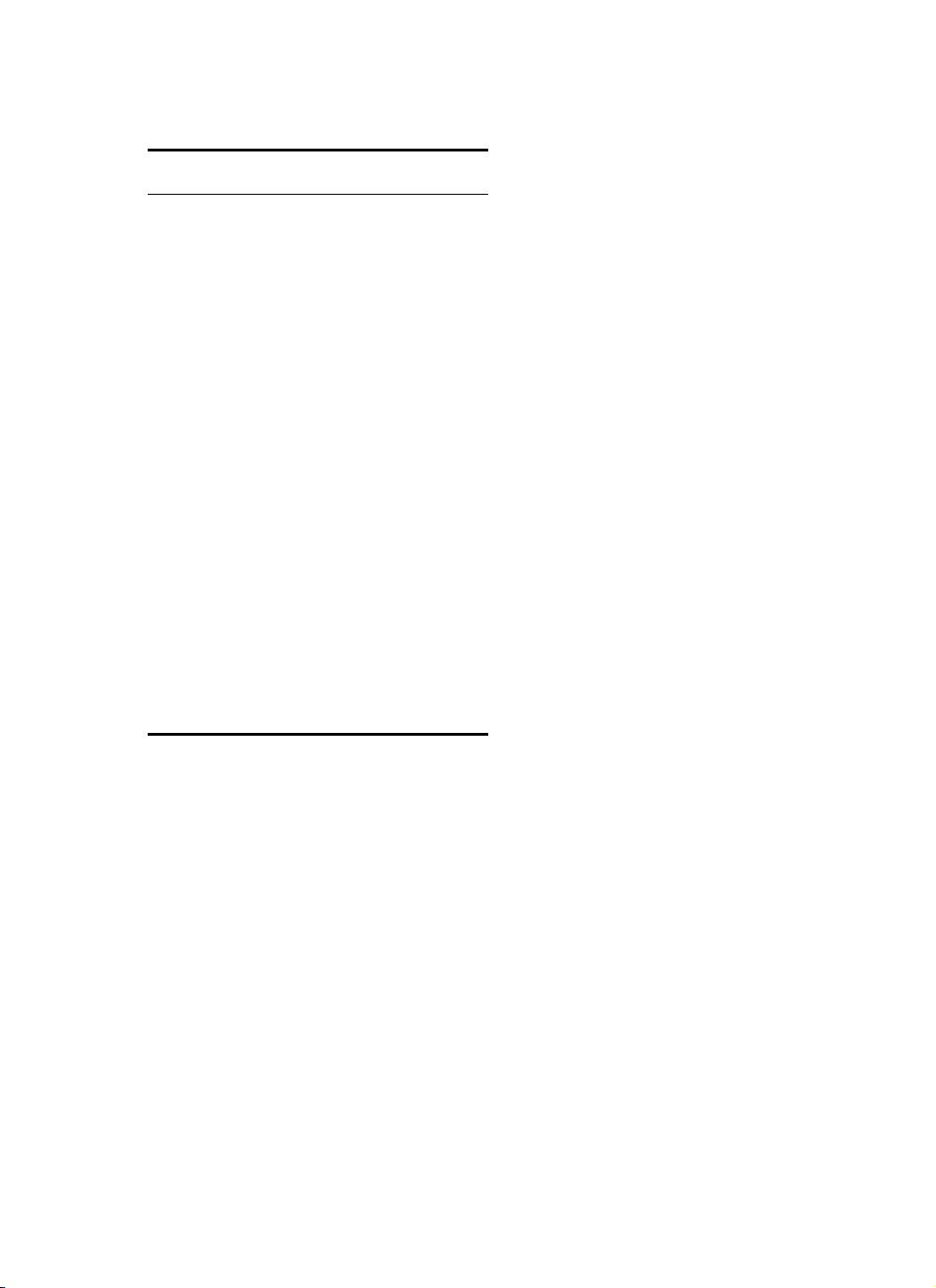

mechanism is also what we call a closed loop. This single-loop system ignores the fact that

the dynamics of the bioreactor involves complex interactions among different variables. If

we want to take a more comprehensive view, we need to design a multiple-input multiple-

output (MIMO), or multivariable, system. When we invoke the term system, we are referring

to the process

4

(the bioreactor here), the controller, and all other instrumentation, such as

sensors, transmitters, and actuators (like valves and pumps) that enable us to control the

pH.

When we change a specific operating condition, meaning the set point, we would like,

for example, the pH of the bioreactor to follow our command. This is what we call

servocontrol. The pH value of the bioreactor is subjected to external disturbances (also

called load changes), and the task of suppressing or rejecting the effects of disturbances

is called regulatory control. Implementation of a controller may lead to instability, and the

issue of system stability is a major concern. The control system also has to be robust such

that it is not overly sensitive to changes in process parameters.

What are some of the issues when we design a control system? In the first place, we need

to identify the role of various variables. We need to determine what we need to control, what

we need to manipulate, what the sources of disturbances are, and so forth. We then need to

state our design objective and specifications. It may make a difference whether we focus on

the servo or on the regulator problem, and we certainly want to make clear, quantitatively, the

desired response of the system. To achieve these goals, we have to select the proper control

strategy and controller. To implement the strategy, we also need to select the proper sensors,

transmitters, and actuators. After all is done, we have to know how to tune the controller.

Sounds like we are working with a musical instrument, but that’s the jargon.

The design procedures depend heavily on the dynamic model of the process to be con-

trolled. In more advanced model-based control systems, the action taken by the controller

actually depends on the model. Under circumstances for which we do not have a precise

model, we perform our analysis with approximate models. This is the basis of a field called

system identification and parameter estimation. Physical insight that we may acquire in the

act of model building is invaluable in problem solving.

Although we laud the virtue of dynamic modeling, we will not duplicate the introduction

of basic conservation equations. It is important to recognize that all of the processes that we

want to control, e.g., bioreactor, distillation column, flow rate in a pipe, drug delivery system,

etc., are what we have learned in other engineering classes. The so-called model equations are

conservation equations in heat, mass, and momentum. We need force balance in mechanical

devices, and, in electrical engineering, we consider circuit analysis. The difference between

what we now use in control and what we are more accustomed to is that control problems are

transient in nature. Accordingly, we include the time-derivative (also called accumulation)

term in our balance (model) equations.

What are some of the mathematical tools that we use? In classical control, our analy-

sis is based on linear ordinary differential equations with constant coefficients – what is

called linear time invariant (LTI). Our models are also called lumped-parameter models,

meaning that variations in space or location are not considered. Time is the only indepen-

dent variable. Otherwise, we would need partial differential equations in what is called

distributed-parameter models. To handle our linear differential equations, we rely heavily

4

In most of the control world, a process is referred to as a plant. Here “process” is used because, in the

process industry, a plant carries the connotation of the entire manufacturing or processing facility.

3