"基于西门子802C数控系统设计项目指导书:伺服控制与电气原理图详解"。

19 浏览量

更新于2024-03-23

收藏 2.27MB DOCX 举报

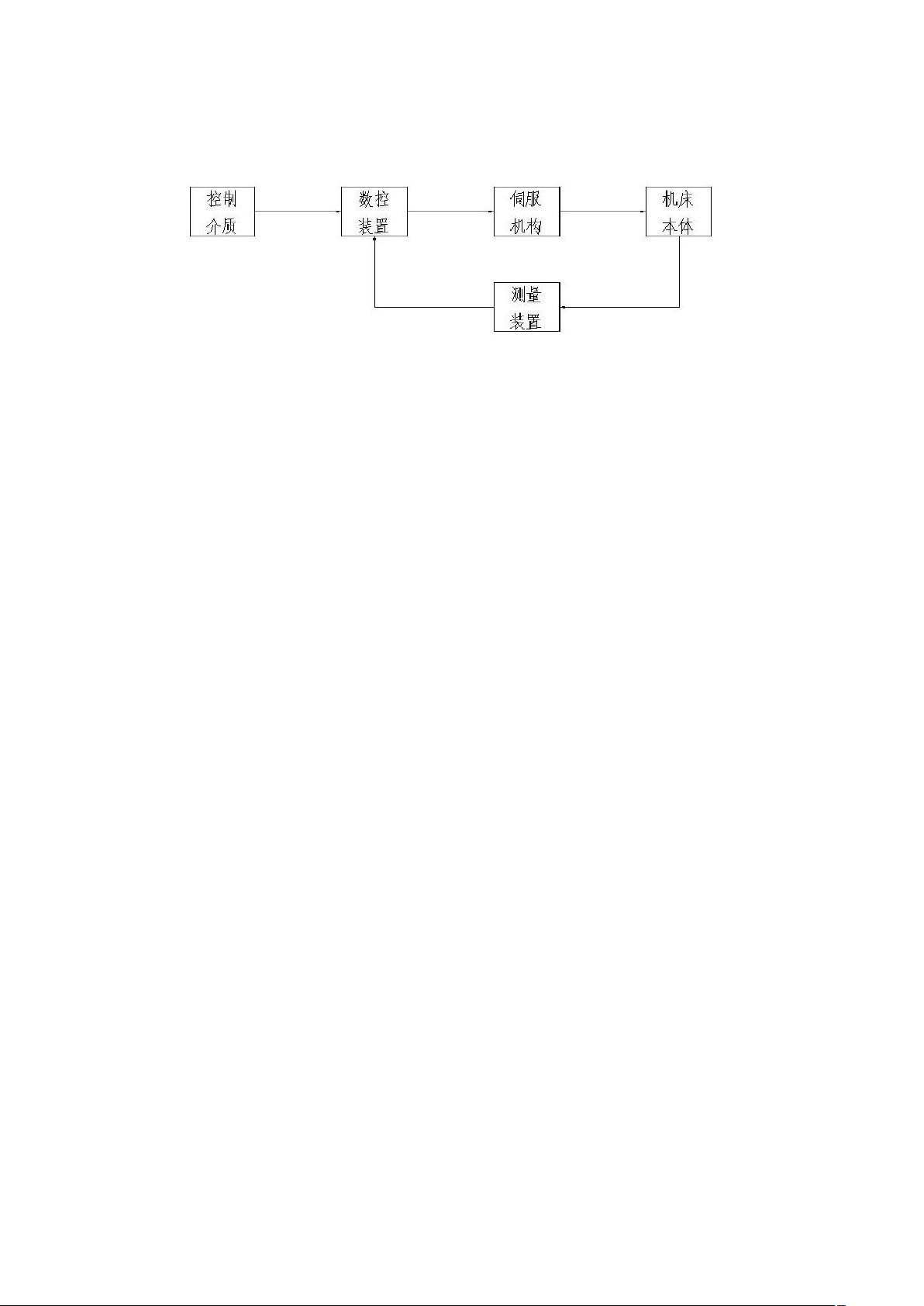

With the continuous progress of science and technology and the development of social productivity, excellent manufacturing technology based on numerical control technology is gradually replacing traditional mechanical manufacturing technology at a faster pace, which has become the current trend of mechanical manufacturing technology development. Numerical control machine tools are widely used in the manufacturing industry, leading to an increasing demand for talents who are proficient in operating, programming, and maintaining numerical control machine tools. Over the years, various universities have opened numerical control majors, reflecting the demand for such talents in society from an educational perspective. However, this also raises the issue of how to cultivate talents who can adapt to engineering applications in numerical control teaching.

This project is based on the Siemens SINUMERIK 802C numerical control lathe control system design. After understanding and mastering the structure, working principle, and control methods of the Siemens 802C numerical control system, the project configured the servo system, spindle control system, and auxiliary motion control system based on it. By consulting relevant materials, the hardware of the numerical control lathe was selected, the working principles of each module were understood, and external hardware circuits were designed. The project ultimately designed a system that can achieve functions such as spindle control, feed motion control, and auxiliary device control.

Through research, the project gained an understanding of the characteristics of the Siemens 802C numerical control system's built-in PLC and designed an automatic turret PLC control program. In addition, critical parameters of the numerical control system were set. The project keywords include Siemens 802C, servo system, spindle control system, and electrical schematics.

101 浏览量

145 浏览量

133 浏览量

2022-04-03 上传

2023-09-13 上传

2023-09-02 上传

2023-09-13 上传

2021-12-13 上传

2022-11-27 上传

智慧安全方案

- 粉丝: 3842

- 资源: 59万+

最新资源

- wp-fakerify:伪造wordpress个人用户数据

- CS-216-Project

- 天池大数据竞赛《广东省政务数据创新大赛——智能算法赛》 数据切分.zip

- bmt_python

- Client-Side-Boot-Camp:客户端新手训练营

- baumwachstum-simulation:Baumwachstum Simulation in Rahmen meiner Bachelorarbeit

- 小程序支付.zip

- “云听”与倒映有声达成战略合作,深耕人工智能语音领域.zip

- person

- andres3119.github.io:个人投资组合

- GitHub Windows Edition:将GitHub转换为Windows 95

- practise-template-method-pattern:初学者的Java基本实践:继承

- 缓存击穿概念讲解.zip

- rust_gui:Rust中基于CrossPlatform Native Widget的组件系统

- 流通企业核心竞争力的铸造与提升

- reflectDHCP:反射 https 的助手