1077-2626 (c) 2015 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission. See

http://www.ieee.org/publications_standards/publications/rights/index.html for more information.

This article has been accepted for publication in a future issue of this journal, but has not been fully edited. Content may change prior to final publication. Citation information: DOI

10.1109/TVCG.2015.2476788, IEEE Transactions on Visualization and Computer Graphics

JOURNAL OF IEEE TRANSACTIONS ON VISUALIZATION AND COMPUTER GRAPHICS, VOL. 13, NO. 9, SEPTEMBER 2015 3

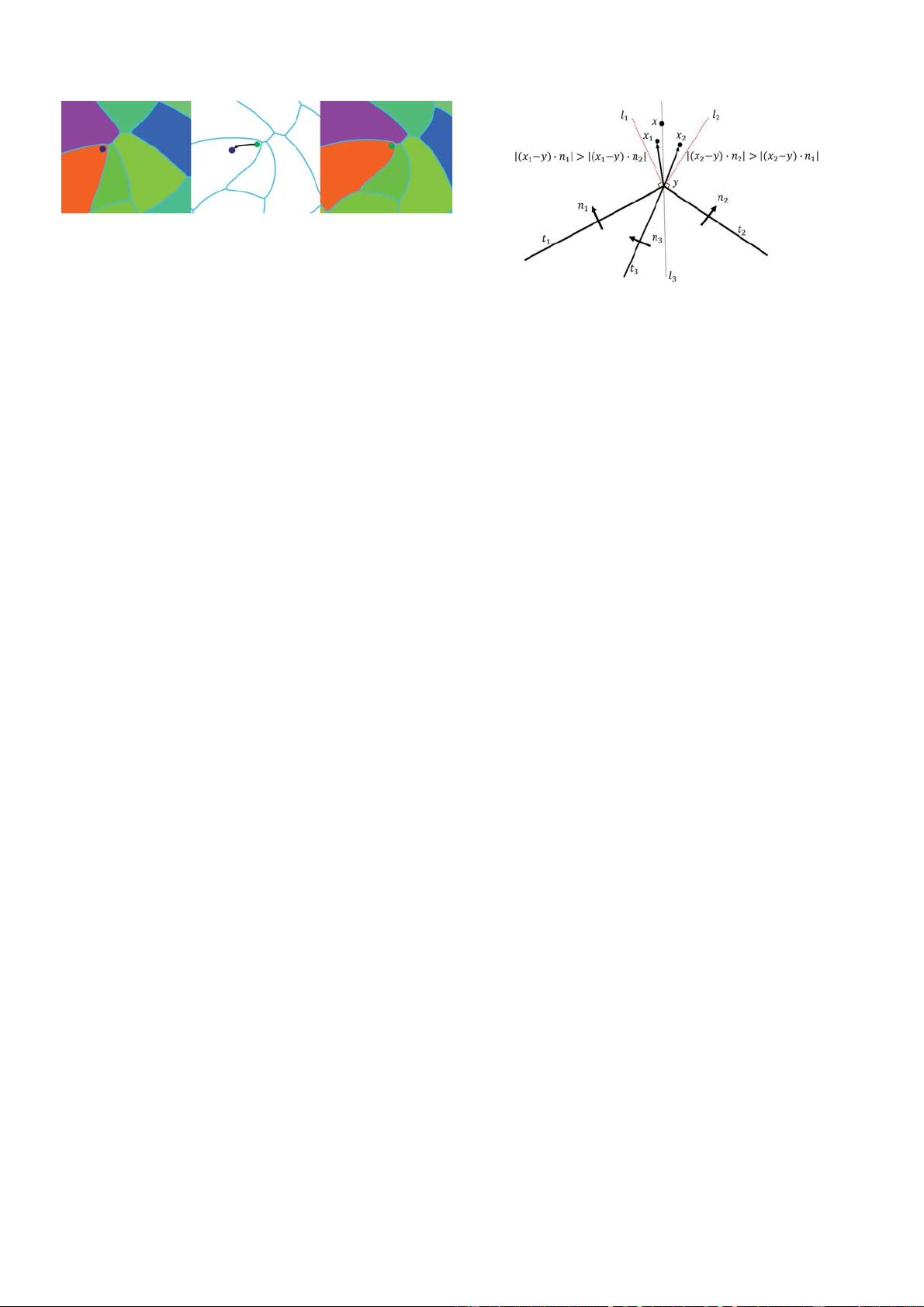

Fig. 1. Update of the distance and indicator functions. Middle: For a point

(green) in space, we trace back a step to find its previous position (blue).

Left: Distance and indicator functions are then updated by exact com-

putation from the interface meshes in previous position. Right: Once the

distance and indicator functions are updated, we process to construct a

new interface mesh with the contouring algorithm.

Now we outline our method, formally. Given an N-

phase problem (see Figure 1) equipped with an unsigned

distance function

φ(x), which denotes the distance mea-

sured from

x to the nearest point on the interface, an

indicator function

χ(x), which indicates the phase material,

and an explicit surface mesh, we formulate the tracking

of multiphase interfaces as a contouring problem which

consists of three steps as follows:

1) Update

φ and χ using semi-Lagrangian method. φ

and χ are computed exactly to improve the accura-

cy.

2) Contour

φ and χ to get the new interface meshes.

This is performed with precomputed stencils com-

bined with bisection to get accurate estimations of

intersections and junctions.

3) Redistance

φ and χ.Asφ is most accurate near the

interface, we propagate the values near the interface

to the whole domain to stay in good accuracy.

To advect

φ(x) and χ(x) forward, we use the semi-

Lagrangian method [33] to backtrace the point

x through the

streamline of the velocity field

v over a time Δt and assign

the new value with the value at its previous location, i.e.,

φ(x)=φ(x − Δtv), χ(x)=χ(x − Δtv). Here, φ(x − Δtv)

is computed from the explicit surface mesh at the previous

time step, according to [7], and the calculation of

χ(x−Δtv)

requires a special treatment to the representation of the

surface meshes (Section 4). Then, we will reconstruct the

surface meshes from

φ and χ instead of advancing the

meshes forward to avoid the complex remeshing during the

topological changes. The key point of this part is to guar-

antee that the reconstructed surface meshes are watertight

and smooth (Section 5). Finally, since it is expensive to track

multiphase interfaces on a uniform grid, we use an octree

(quadtree in 2D) to store

φ and χ. We only maintain the

finest cells near the interfaces. As long as the interfaces

are moved, we will adjust the tree’s structure to keep it

balanced. Section 6 gives the details how to build the octree

to well resolve

φ and χ and how to compute φ and χ for the

tree structure efficiently.

4DISTANCE AND INDICATOR COMPUTATION

Our multiphase system consists of two parts: an implicit

part, which contains an unsigned distance function

φ as

well as an indicator function

χ, and an explicit part, which

corresponds to the surface meshes. Since the implicit part is

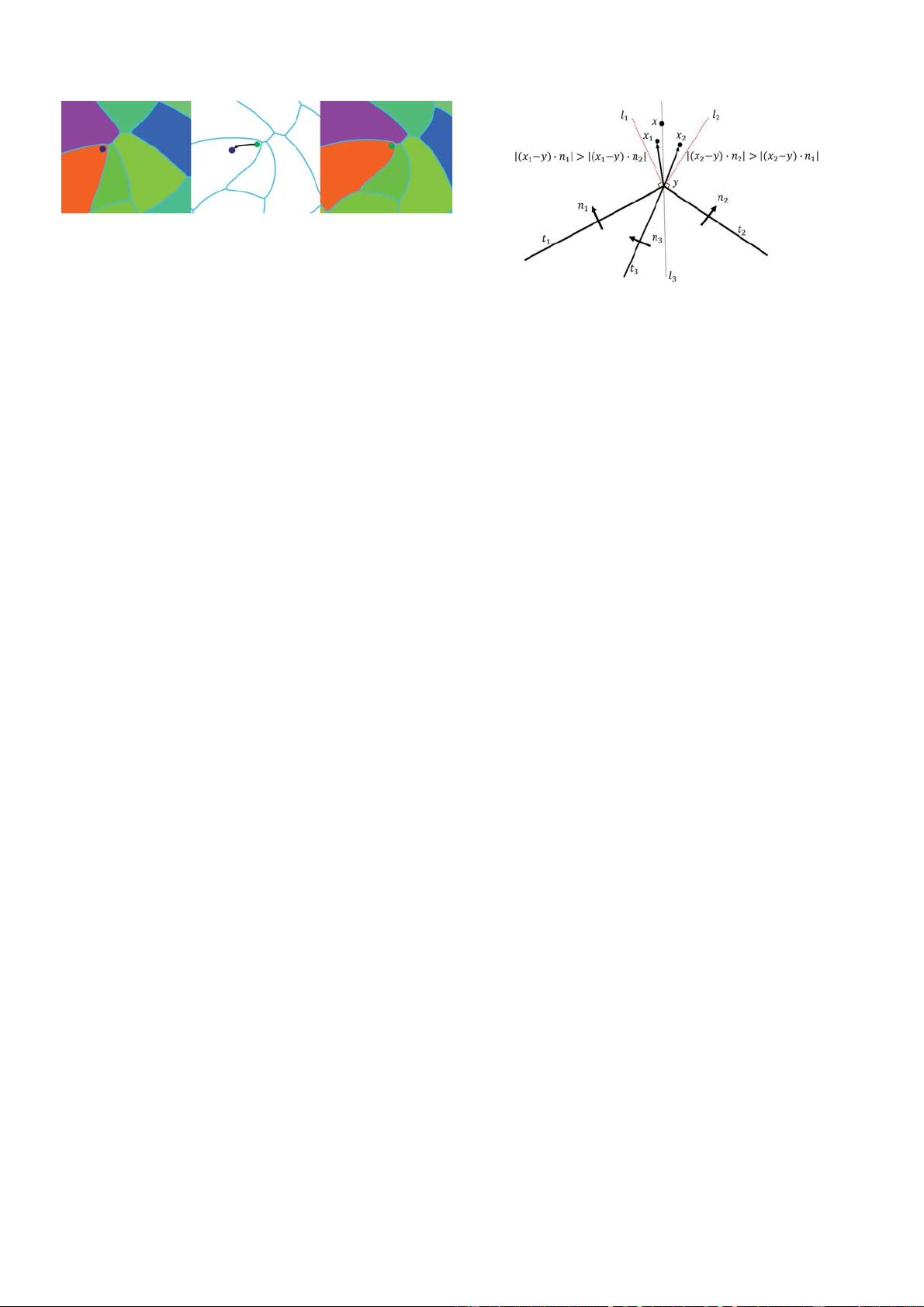

Fig. 2. Indicator computation near a vertex. Only when two neighboring

segments form an angle no less than 180 degrees, the closest point y

can lie on the vertex. In such case, x must lie in the region form by l

1

and l

2

. l

1

and l

2

are perpendicular to t

1

and t

2

respectively. For x

1

, n

1

is used to compute the indicator value while n

2

is used for x

2

according

to our method. In a non-manifold setting, there can be a third segment

incident on a vertex, say t

3

. Imagine rotating t

1

and t

2

about vertex y to

t

3

, we can easily see that |E| = |(x − y ) · n

3

| is always smaller than that

of t

1

or t

2

as |E| keep decreasing to zero when rotating t

1

and t

2

to l

3

until one of them gets over t

3

. Thus, t

1

or t

2

is always used to compute

the indicator value accurately.

similar to the one in VIIM, we only discuss the explicit part

here.

To avoid complicated remeshing operations, we will

always reconstruct the surface meshes from the isocontour

φ(x)=0, from which both the distance function and the

indicator function can be updated accurately. The explicit

representation of the surface mesh is similar to [7], except

that the triangle mesh in our method may be non-manifold

(one edge is shared by more than two triangles) and contains

complex structures such as the T-junctions. Then, it raises

a question: how can we identify a material at any point

x without using a binary inside/outside classification of

space? In our implementation, we follow Da and the col-

leagues’ work [34] to assign a unique integer label to each

material and apply different labels to the front and back

of each triangle. Besides, we store an extra normal on each

face of the triangle mesh to facilitate the calculation of the

indicator function. The normal will be always pointing from

a higher material label to a lower one. Now, we will show

how such information is used to divide the entire problem

domain into separate regions of materials.

4.1 Material Identification

Since the distance function can be computed according

to [7], we only discuss how to get the indicator function

here. We first consider a 2D case. For an arbitrary point

x, we denote its closest point on the curve as y and the

corresponding normal as

n(y), which is assumed to point

from material

A to B. To identify the material label for x,

we first calculate the following quantity:

E =(x − y) · n(y) (1)

If

y lies inside the edge, the material label can easily be

determined from the sign of

E. More specifically, E > 0

means the point x belongs to material B while E < 0

means it belongs to material A. However, if the point y

lies on the vertex, different values of E can be obtained if we

use the normal defined on different edges. We remove this

ambiguity by choosing the one with the maximum value of