没有合适的资源?快使用搜索试试~ 我知道了~

首页ASHRAE IJHVAC 11-4: 美国采暖与制冷工程研究

ASHRAE IJHVAC 11-4: 美国采暖与制冷工程研究

1.该资源内容由用户上传,如若侵权请联系客服进行举报

2.虚拟产品一经售出概不退款(资源遇到问题,请及时私信上传者)

2.虚拟产品一经售出概不退款(资源遇到问题,请及时私信上传者)

版权申诉

PDF格式 | 12.21MB |

更新于2024-07-20

| 83 浏览量 | 0 下载量 举报

"ASHRAE IJHVAC 11-4.pdf" 是一份由ASHRAE(美国采暖与制冷工程协会)出版的国际期刊《Heating, Ventilating, Air-conditioning and Refrigerating Research》(HVAC&R研究)的文章。该期刊主要关注供暖、通风、空调及制冷领域的科学研究和技术发展。

ASHRAE是美国的一个专业组织,致力于推进暖通空调(HVAC)和制冷技术的科学、工程和教育领域。这个协会通过制定标准、出版物和研讨会,对全球的建筑环境和能源效率产生了深远影响。ASHRAE的标准和指南被广泛用于设计、建设和运营建筑物的暖通空调系统,以确保舒适性、能效和环保性能。

该期刊的编辑团队由行业内知名专家组成,包括主编Reinhard Radermacher教授,他同时是美国马里兰大学机械工程系的环境能源工程中心主任。副编辑包括James E. Braun教授、Alberto Cavallini教授、Qingyan (Yan) Chen教授和Srinivas Garimella博士,他们分别在Purdue大学、意大利帕多瓦大学以及艾奥瓦州立大学担任教学和研究工作。这些专家在全球暖通空调和制冷领域的研究中有着显著的贡献。

期刊中的文章通常涵盖了广泛的议题,可能包括热力学、流体力学、传热学、热舒适性、能源效率、室内空气质量、制冷剂替代、建筑能源模拟、系统设计优化、智能控制系统等方面的研究。通过这些研究,ASHRAE期刊推动了行业内的技术创新和知识更新,为工程师、研究人员、学生和政策制定者提供了宝贵的资源,以应对不断变化的环境和能源挑战。

由于文档中并未提供具体的文章内容,所以无法详细阐述特定的研究成果或讨论点。然而,可以肯定的是,ASHRAE IJHVAC 11-4.pdf中包含的论文将深入探讨HVAC&R领域的最新进展和挑战,读者可以通过这份资料了解到行业的前沿技术和理论研究。对于从事相关行业工作的专业人士来说,这是一个不可或缺的学习和参考来源。

516

HVAC&R

RESEARCH

oil concentration. The authors attributed this to the increase of the mixture viscosity. By assum-

ing annular flow, the authors proposed an empirical correlation. The correlation had the same

form for both the pure refrigerant and refrigerantíoil mixtures. In the case of the refìigerant/oil

mixture, the refrigeranuoil mixture viscosity and density were used in the correlation. As a

result, the predicted heat transfer coefficient of the refrigeranuoil mixtures had the same accu-

racy as that

of

the pure refngerant. It has to be noted that the reviewed literature studies did not

veri@ the hypothesis that the condensation heat transfer coefficient consistently increases as

the viscosity of the oil decreases. It seems that other factors, such as mass flux, the resulting

flow regime, and the dew point, have impacts on the condensing heat transfer coefficient as

well and can compensate the impact of the viscosity. For example, Eckcls

et

al. (1994b)

reported that the mixture of R-134a-169

SUS

oil has a higher heat transfer coefficient at low

mass flux and a lower heat transfer coefficient at high mass flux compared to the mixture of

R-134a-369

SUS

oil, although the 369

SUS

oil has a higher viscosity than the 169

SUS

oil. It

indicates that the increased mixture viscosity may not be the only factor to imp&t the conden-

sation heat transfer coefficient.

Effect

of

Vapor

Quality.

Cho and Tae

(2001)

found that the heat transfer coefficient of

R-22/oil and R-407C/oil decreased with an increase in inlet quality. The author attributed this to

an increase in average liquid phase viscosity. Cawte (1992) indicated that the presence of oil at

low concentrations has an insignificant effect on the heat transfer coefficient at low qualities but

becomes more pronounced at higher qualities. However, at high oil concentrations of 10% or

more, the oil presence affects the heat transfer coefficient uniformly over the entire quality range

due to the pronounced increase in liquid viscosity. Fukushima and Kudou (1990) studied the

condensation heat transfer of refrigerandoil mixtures at varying qualities. The authors reported

on a specific heat transfer characteristic of refrigerant/oil mixtures during condensation. In gen-

eral, the pure refngerant condensation coefficient decreases toward lower vapor qualities

because the liquid film is getting thicker. In case of refrigerant/oil mixtures, the authors

observed a maximum in heat transfer coefficient since there are

two

opposing factors in the liq-

uid film that affect the heat transfer coefficient. At high vapor qualities, the liquid film is thin

but oil-rich, which results in a higher mass transfer resistance effect and higher viscosity in the

film. As the vapor quality decreases, the liquid film becomes thicker, but more dissolved refrig-

erant decreases the effects

of

the lubricant in the film. Hence, there was a peak of the condensing

heat transfer coefficient when quality decreased, which was apparent at high oil concentration.

In general, there is little agreement about the lubricant influences at high vapor quality regions.

At high qualities, the viscosity and mass transfer resistance effect in the liquid film are more

pronounced, which may reduce the heat transfer. However, high oil concentrations at high vapor

qualities result in a significant increase in the dew temperature, which increases the heat transfer

driving potential. Thus, there is a trade-off in heat transfer at high qualities.

Research Methods and Correlations for Refrigerant/Oil Convective Condensation

The lubricant influence on convective condensation heat transfer

is

rather consistent in that it

always seems

to

degrade the heat transfer. Thome (1998) concluded that the increase in mixture

viscosity due to the oil is the most important factor influencing the heat transfer. Thome recom-

mended using the refrigerant/oil mixture liquid viscosity directly in a pure refrigerant correla-

tion. He indicated that this method would predict accurate tendencies due to the increase of the

oil

concentration with quality. Schlager et al. (1990) indicated that the refrigerant/oil mixture

properties can be substituted into pure refrigerant correlation to predict the mixture’s heat trans-

fer coefficient only if the lubricant (the second component) does not cause an unexpected phe-

nomenon in the mixture. Thus, it seems feasible to use a correlation for the pure refrigerant heat

transfer coefficient to predict the heat transfer coefficient of the refrigeradoi1 mixture by

Copyright ASHRAE

Provided by IHS under license with ASHRAE

Licensee=Naval Aviation Depot/5918326100

Not for Resale, 01/19/2008 02:31:08 MST

No reproduction or networking permitted without license from IHS

--`,`,`,``,,`,`,,,`,``,,,`,`,,``-`-`,,`,,`,`,,`---

VOLUME

1

1,

NUMBER

4,

OCTOBER

2005

517

replacing the pure refrigerant properties with the mixture's properties. Sur and Azer (199 1) used

the Kaushik and Azer (1988) correlation and the mixture properties from Baustian et al. (1986a)

to predict the condensation heat transfer coefficient inside an internally finned tube. Schlager et

al. (1990) substituted the mixture properties into condensation correlations of Shah (1979), Cav-

allini and Zecchin (1974), and Traviss et al. (1972) to predict the mixture behavior in a plain

tube, Shao and Granryd (1995) used the correlations of Shah (1979) and Tandon et al. (1995)

with mixture properties to predict the condensation heat transfer coefficient

of

refrigerantloil

mixtures. All these investigators obtained results that were reasonably good.

Dobson and Chato (1 998) recommended their flow-pattern-dependent correlation, which was

revised with the correction factor of Schlager et al. (1990) for the application of refrigeradoi1

condensing in smooth tubes, as shown in Equation 1.

The collected semi-empirical refrigeradoi1 condensation correlations are: Tichy et al. (1 985)

for R-12-300-SUS; Schlager et al. (1990) for R-22-150-SUS and R-22-300-SUS; Sur and Azer

(1991) for R-113-150-SUS; Cawte (1992) for R22-Shell Clavus 32 oil; Eckels et al. (1994b,

1998a) for R-134a-169-SUS, R-134a-369-SUS, and R-134a-150-SUS; Shao and Granryd

(1995) for R-134a-ester oil with viscosity of 32 CSt; and Usmani and Ravigururajan (1999) for

R-22-oi1, R-134a-oi1, and R-12-oil.

LUBRICANT INFLUENCE ON REFRIGERANT PRESSURE DROP

General Phenomena

Most of the reviewed studies reported that the oil presence increases the pressure drop during

the evaporation and condensation. The presence of oil has a larger influence on convective evap-

oration than on convective condensation. In most cases, the increased mixture viscosity was

used to explain this phenomenon. Schlager et al. (1987) cited two other possible explanations

for the increase in pressure drop: the first explanation is that the relatively thick oil film reduces

the flow area. The second explanation is that the use of

a

miscible oil resulted in an earlier for-

mation of annular flow, which increases the pressure drop, compared to the stratified flow.

Shao and Granryd (1994, 1995) reported on the pressure drop performance

of

R-134doil mix-

tures in a horizontal condensing tube and compared it with pure refrigerant. The authors found a

20% pressure drop increase when oil was present. Tichy et al. (1986) reported that for the same

mixture the pressure drop increase during evaporation was larger than during condensation.

During condensation, Tichy et al. observed 2% and 6% increases in pressure drop at 2% and 5%

oil mass concentrations, respectively. However, the corresponding increases in pressure drop

were 63% and 86% for evaporation. They attributed this difference to different flow patterns.

The dominant flow pattern during convective condensation is stratified flow, while the one in

convective evaporation is mostly annular flow. Stratified flow has a lower increase in shear

stress due to the increased viscosity with oil concentration, whereas the increased mixture vis-

cosity increases the shear stress pronouncedly in annular flow.

Schlager et al. (1988) reported on the evaporation and condensation of R-22 with 150-SUS oil

and 300-SUS oil in a smooth tube, a low-fin tube, and a micro-fin tube. During evaporation,

both refrigerandoil mixtures increased the pressure drop in all three tubes. There was no

apparent difference between the two lubricants studied.

The

pressure drop penalty ratio

increased with oil fraction. An increase in mass flux had a trend to reduce the adverse effect due

to the oil presence. It seemed that the oil presence had less effect on the enhanced tubes than on

the smooth tubes; e.g., the evaporation pressure drop penalty ratio due

to

oil presence was the

Copyright ASHRAE

Provided by IHS under license with ASHRAE

Licensee=Naval Aviation Depot/5918326100

Not for Resale, 01/19/2008 02:31:08 MST

No reproduction or networking permitted without license from IHS

--`,`,`,``,,`,`,,,`,``,,,`,`,,``-`-`,,`,,`,`,,`---

518

HVAC&R

RESEARCH

smallest in the low-fin tubes. In comparison, the oil presence during condensation had less

negative effects than during evaporation.

Eckels et al. (1994a, 1994b) studied the evaporation and condensation of R-134a with

169-SUS oil and 369-SUS oil in a smooth tube and a micro-fin tube. During evaporation, both

the 169-SUS oil and the 369-SUS oil increased the pressure drop in smooth and micro-fin tubes,

as compared to pure

R-

134a, and the pressure drop increased with oil concentration. There was

no apparent difference between these

two

lubricants. The oil presence tended to increase the

pressure drop penalty ratio more in smooth tubes than that in micro-fin tubes. Such effect

became apparent at high oil concentration. In addition, the authors found that the pressure drop

penalty ratio was inclined to decrease with mass flux. During condensation, Eckels et al. pointed

out that the 169-SUS oil drastically increased the condensation pressure drop, which is inconsis-

tent with the generally negligible effect of oil presence on the condensation pressure drop. Eck-

els et al. (1 998a) also studied the evaporation and condensation of R- 134a with 150-SUS oil in a

smooth tube and a micro-fin tube; they reported basically the same results as Eckels et al.

(1994a, 1994b). The authors (Eckels et al. 1998b) also investigated the pressure drop perfor-

mance of R-134d169-SUS oil in different diameter smooth tubes and micro-fin tubes. During

evaporation, the lubricant had a less adverse effect on the pressure drop in the tubes with larger

diameters than those with smaller diameters. During condensation, the lubricant impacted the

different diameter micro-fin tubes similarly. However, the lubricant had a larger adverse effect

on the smaller diameter smooth tube than on the larger diameter smooth tube.

The flow boiling of R-407C and R-407C/oil mixture in a micro-fin tube and a smooth tube

was reported by Zurcher et al. (1999a, 1999b). The authors observed that the oil presence in

R-407C always increased the pressure drop during evaporation. The pressure drop increase

increased with oil addition and local vapor quality. The lubricant influenced the two-phase pres-

sure drop drastically at high vapor quality, where the local oil mass concentrations were the larg-

est. The authors indicated that the increased pressure drop was mainly due to the increased

mixture viscosity and that the foaming behavior of the R-407C-oil mixture might have an influ-

ence on the pressure drop. These results were consistent with the results the authors obtained

during their experiments of R-134a-oil mixtures (Zurcher et al. 1997).

Unusual Phenomena

It

should be noted that there is a unique phenomenon with respect to the lubricant influence

on refrigerant pressure drop. Some lubricants were found to reduce the pressure drop of the

refrigerantíoil mixture. During the tests

of

R-22/oil mixtures, Schlager et al. (1988) observed

that the addition of 150-SUS and 300-SUS lubricants decreased the condensation pressure drop

in smooth tubes. However, this effect was not found in micro-fin tubes and low-fin tubes. Eckels

et al. (1994b) found that the addition of 369-SUS lubricant reduced the condensation pressure

drop of R-134a in smooth tubes. The addition of 369-SUS lubricant also reduced the pressure

drop in micro-fin tubes to a lesser degree. However, the authors observed that the addition of

169-SUS lubricant did not reduce the condensation pressure drop in all of the tubes, although it

got a smaller lubricant viscosity. Zurcher et al. (1999b) reported an anomalous pressure drop

decrease in the quality range

from

5%

to 70% at mass flux of

200

kg/(m2

.

s)

for R-134doil mix-

tures, but no such phenomenon was observed in the tests of other mass fluxes and with

R-407C/oil mixtures.

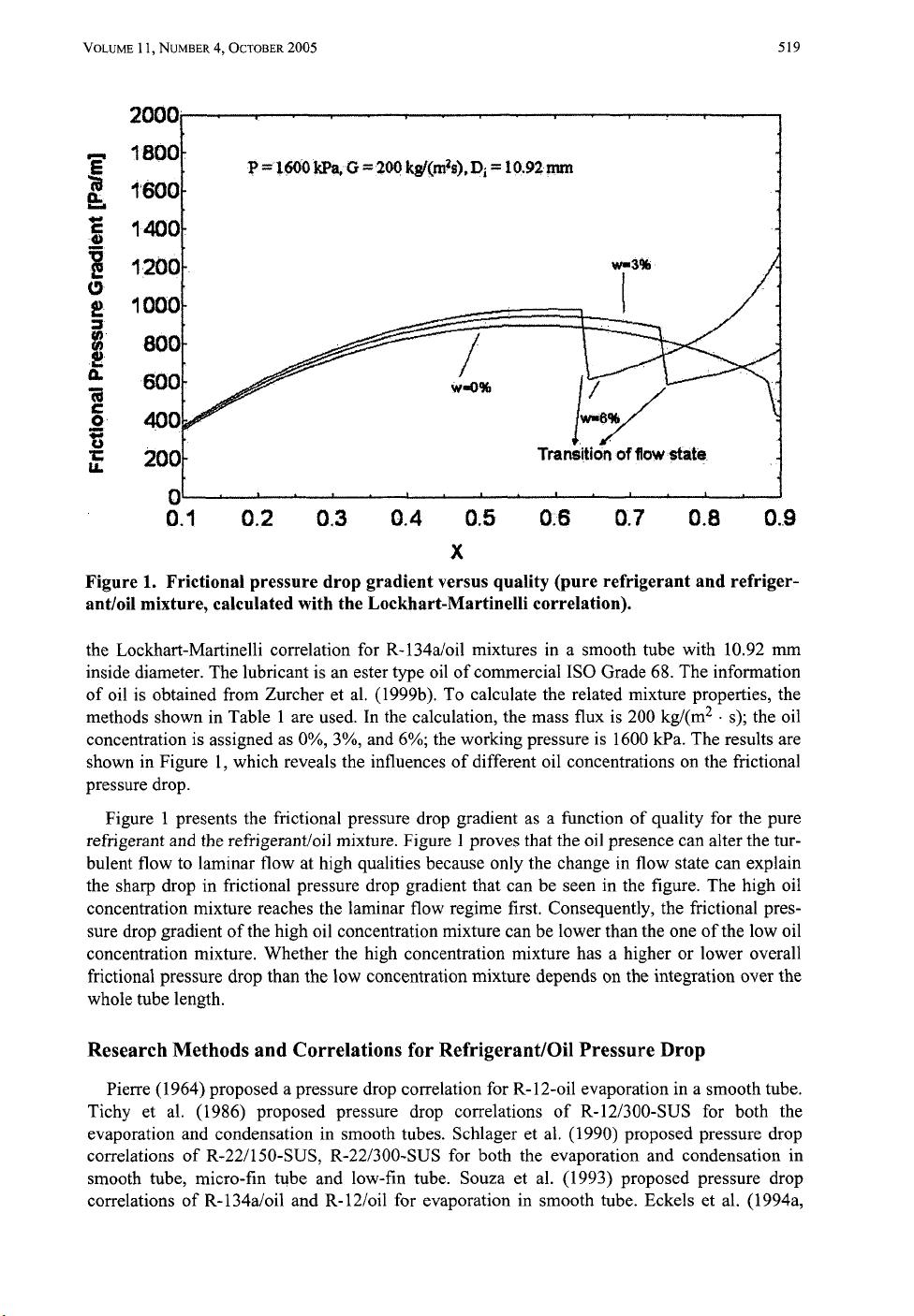

Most of the pure refrigerant pressure drop correlations are based on the assumption of turbu-

lent flow. However, the oil presence can increase the mixture viscosity of the liquid film at high

quality

so

significantly that the flow state is likely to be changed to laminar flow. The Lock-

hart-Martinelli pressure drop correlation supports this hypothesis, for the correlation can study

the flow state in detail using the local mixture properties. Here, an analysis was conducted using

Copyright ASHRAE

Provided by IHS under license with ASHRAE

Licensee=Naval Aviation Depot/5918326100

Not for Resale, 01/19/2008 02:31:08 MST

No reproduction or networking permitted without license from IHS

--`,`,`,``,,`,`,,,`,``,,,`,`,,``-`-`,,`,,`,`,,`---

VOLUME

1

1,

NUMBER

4,

OCTOBER

2005

519

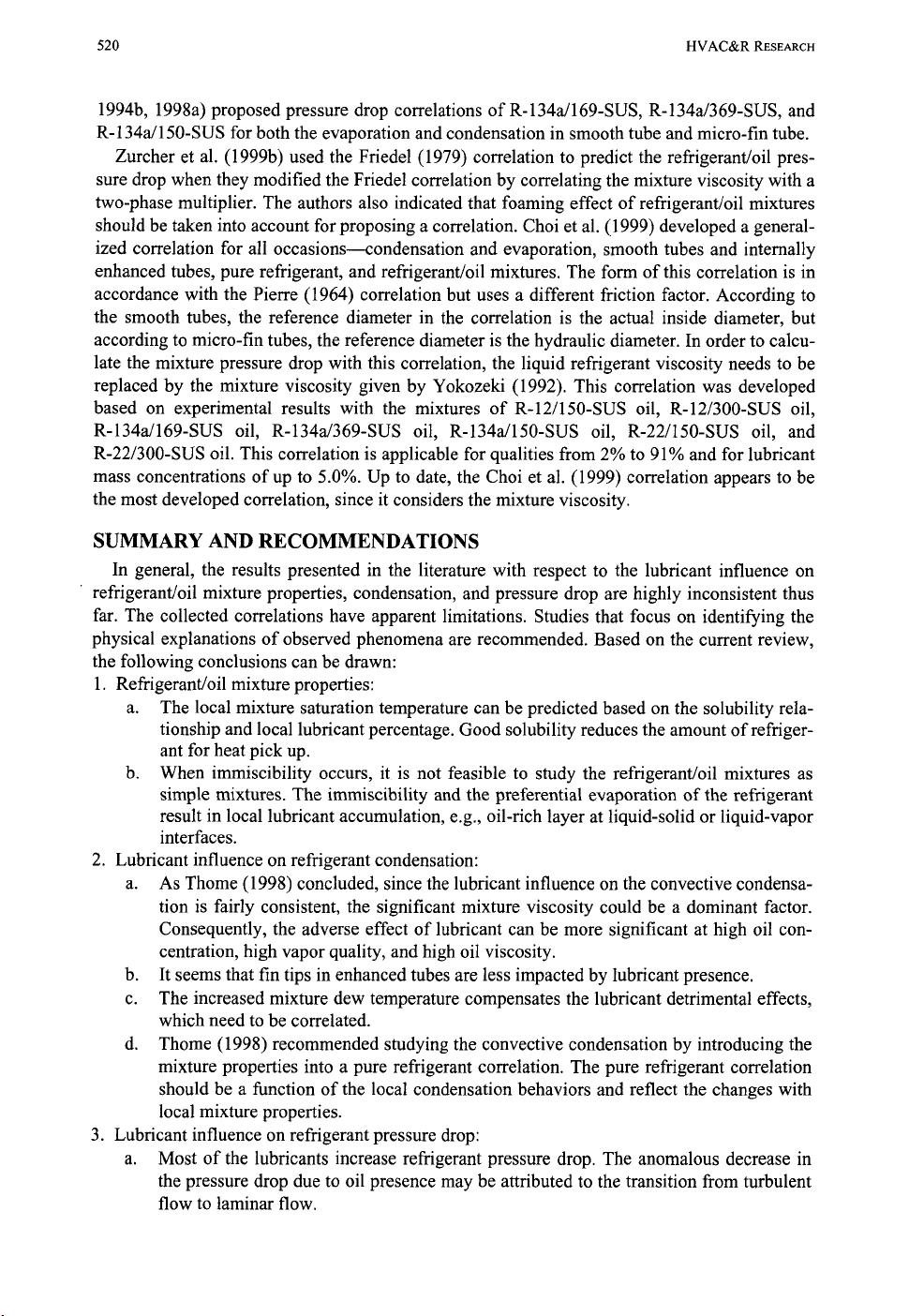

P

=

1600

kPa,

G

=

200

kg/(rnzs).

Di

=

10.92

mm

1600

Y

e!

a

f

3

o

3

1=

U

12001

100ot

r3%

I

A

2001

.I../

Transition

of

flow

state

OL

e

I

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

X

Figure

1.

Frictional pressure drop gradient versus quality (pure refrigerant and refriger-

antloil mixture, calculated with the Lockhart-Martinelli correlation).

the Lockhart-Martinelli correlation for R-134aJoil mixtures in a smooth tube with 10.92 mm

inside diameter. The lubricant is an ester type oil of commercial

IS0

Grade 68. The information

of oil

is

obtained from Zurcher et al. (1999b). To calculate the related mixture properties, the

methods shown in Table 1 are used. In the calculation, the mass flux is 200 kg/(m2

.

s);

the oil

concentration is assigned as

O%,

3%, and

6%;

the working pressure is 1600 kPa. The results are

shown in Figure

1,

which reveals the influences of different oil concentrations on the frictional

pressure drop.

Figure 1 presents the frictional pressure drop gradient as a function of quality for the pure

refrigerant and the refrigeranuoil mixture. Figure

1

proves that the oil presence can alter the tur-

bulent flow to laminar flow at high qualities because only the change in flow state can explain

the sharp drop in frictional pressure drop gradient that can be seen in the figure. The high oil

concentration mixture reaches the laminar

flow

regime first. Consequently, the frictional pres-

sure drop gradient of the high

oil

concentration mixture can be lower than the one of the low oil

concentration mixture. Whether the high concentration mixture has a higher or lower overall

frictional pressure drop than the low concentration mixture depends on the integration over the

whole tube length.

Research Methods and Correlations for Refrigerant/Oil Pressure Drop

Pierre (1964) proposed a pressure drop correlation for R-12-oil evaporation in a smooth tube.

Tichy et al. (1986) proposed pressure drop correlations of R-12/300-SUS for both the

evaporation and condensation in smooth tubes. Schlager et al. (1990) proposed pressure drop

correlations of R-22/150-SUS, R-22/300-SUS for both the evaporation and condensation in

smooth tube, micro-fin tube and low-fin tube. Souza et al. (1993) proposed pressure drop

correlations of R-134doil and R-l2/oil for evaporation in smooth tube. Eckels et al. (1994a,

Copyright ASHRAE

Provided by IHS under license with ASHRAE

Licensee=Naval Aviation Depot/5918326100

Not for Resale, 01/19/2008 02:31:08 MST

No reproduction or networking permitted without license from IHS

--`,`,`,``,,`,`,,,`,``,,,`,`,,``-`-`,,`,,`,`,,`---

520

HVAC&R

RESEARCH

1994b, 1998a) proposed pressure drop correlations of R-134a/169-SUS, R-134a/369-SUS, and

R-134aí150-SUS for both the evaporation and condensation in smooth tube and micro-fin tube.

Zurcher et al. (1999b) used the Friedel (1979) correlation to predict the refrigerantíoil pres-

sure drop when they modified the Friedel correlation by correlating the mixture viscosity with a

two-phase multiplier. The authors also indicated that foaming effect of refrigerant/oil mixtures

should be taken into account for proposing a correlation. Choi et al. (1999) developed a general-

ized correlation for all occasions-condensation and evaporation, smooth tubes and internally

enhanced tubes, pure refrigerant, and refrigerant/oil mixtures. The form of this correlation is in

accordance with the Pierre (1964) correlation but uses a different friction factor. According to

the smooth tubes, the reference diameter in the correlation is the actual inside diameter, but

according to micro-fin tubes, the reference diameter is the hydraulic diameter. In order to calcu-

late the mixture pressure drop with this correlation, the liquid refrigerant viscosity needs to be

replaced by the mixture viscosity given by Yokozeki (1992). This correlation was developed

based on experimental results with the mixtures of R-12/150-SUS

oil,

R-l2/300-SUS oil,

R-134a/169-SUS oil, R-134d369-SUS oil, R-134aí150-SUS oil, R-22/150-SUS oil, and

R-22/300-SUS oil. This correlation is applicable for qualities from 2% to 91% and for lubricant

mass concentrations of up to 5.0%. Up to date, the Choi et al. (1999) correlation appears to be

the most developed correlation, since it considers the mixture viscosity.

SUMMARY AND RECOMMENDATIONS

In general, the results presented in the literature with respect to the lubricant influence on

refrigerantíoil mixture properties, condensation, and pressure drop are highly inconsistent thus

far. The collected correlations have apparent limitations. Studies that focus on identieing the

physical explanations of observed phenomena are recommended. Based on the current review,

the following conclusions can be drawn:

1. Refiigerantíoil mixture properties:

a.

The local mixture saturation temperature can be predicted based on the solubility rela-

tionship and local lubricant percentage. Good solubility reduces the amount of refriger-

ant for heat pick up.

When immiscibility occurs, it is not feasible to study the refrigerant/oil mixtures as

simple mixtures. The immiscibility and the preferential evaporation of the refrigerant

result in local lubricant accumulation, e.g., oil-rich layer at liquid-solid or liquid-vapor

interfaces.

As

Thome (1 998) concluded, since the lubricant influence on the convective condensa-

tion is fairly consistent, the significant mixture viscosity could be a dominant factor.

Consequently, the adverse effect of lubricant can be more significant at high oil con-

centration, high vapor quality, and high oil viscosity.

It seems that fin tips in enhanced tubes are less impacted by lubricant presence.

The increased mixture dew temperature compensates the lubricant detrimental effects,

which need to be correlated.

Thome (1 998) recommended studying the convective condensation by introducing the

mixture properties into a pure refrigerant correlation. The pure refiigerant correlation

should be a function of the local condensation behaviors and reflect the changes with

local mixture properties.

Most of the lubricants increase refrigerant pressure drop. The anomalous decrease in

the pressure drop due to oil presence may be attributed to the transition from turbulent

flow to laminar flow.

b.

2. Lubricant influence on refrigerant condensation:

a.

b.

c.

d.

3. Lubricant influence on refrigerant pressure drop:

a.

Copyright ASHRAE

Provided by IHS under license with ASHRAE

Licensee=Naval Aviation Depot/5918326100

Not for Resale, 01/19/2008 02:31:08 MST

No reproduction or networking permitted without license from IHS

--`,`,`,``,,`,`,,,`,``,,,`,`,,``-`-`,,`,,`,`,,`---

剩余201页未读,继续阅读

相关推荐

制冷技术咨询与服务

- 粉丝: 4070

- 资源: 2万+

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

最新资源

- 两个环信聊天demo.7z

- Pytorch_tutorial

- 二进制时钟:以二进制表示显示时钟时间-matlab开发

- poketcg:神奇宝贝TCG的拆卸

- ShipMMGmodel.zip

- typora-setup-x64.rar

- Hackernews-Node

- U12_Windows_Driver.zip

- 职业危害防治管理规章制度汇编

- 语境

- 安卓QQ聊天界面源代码

- Gardeningly - Latest News Update-crx插件

- calculator:使用 javascript 构建基本计算器

- JavaCalculatorApplication

- bnf:解析BNF语法定义

- COSC-350

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功