"高性能低成本共烧陶瓷(LTCC)设计自动化与优化技术"

需积分: 10 192 浏览量

更新于2024-04-02

收藏 2.16MB PDF 举报

Automating and Optimizing High Performance Low Temperature Co-Fired Ceramic (LTCC) Design is a crucial process in the world of electronics manufacturing. LTCC technology allows engineers to create passive components in a substrate, enabling them to minimize size and increase functionality in electronic devices. However, designing LTCC components comes with its challenges, such as high cost and manual labor involved in the process.

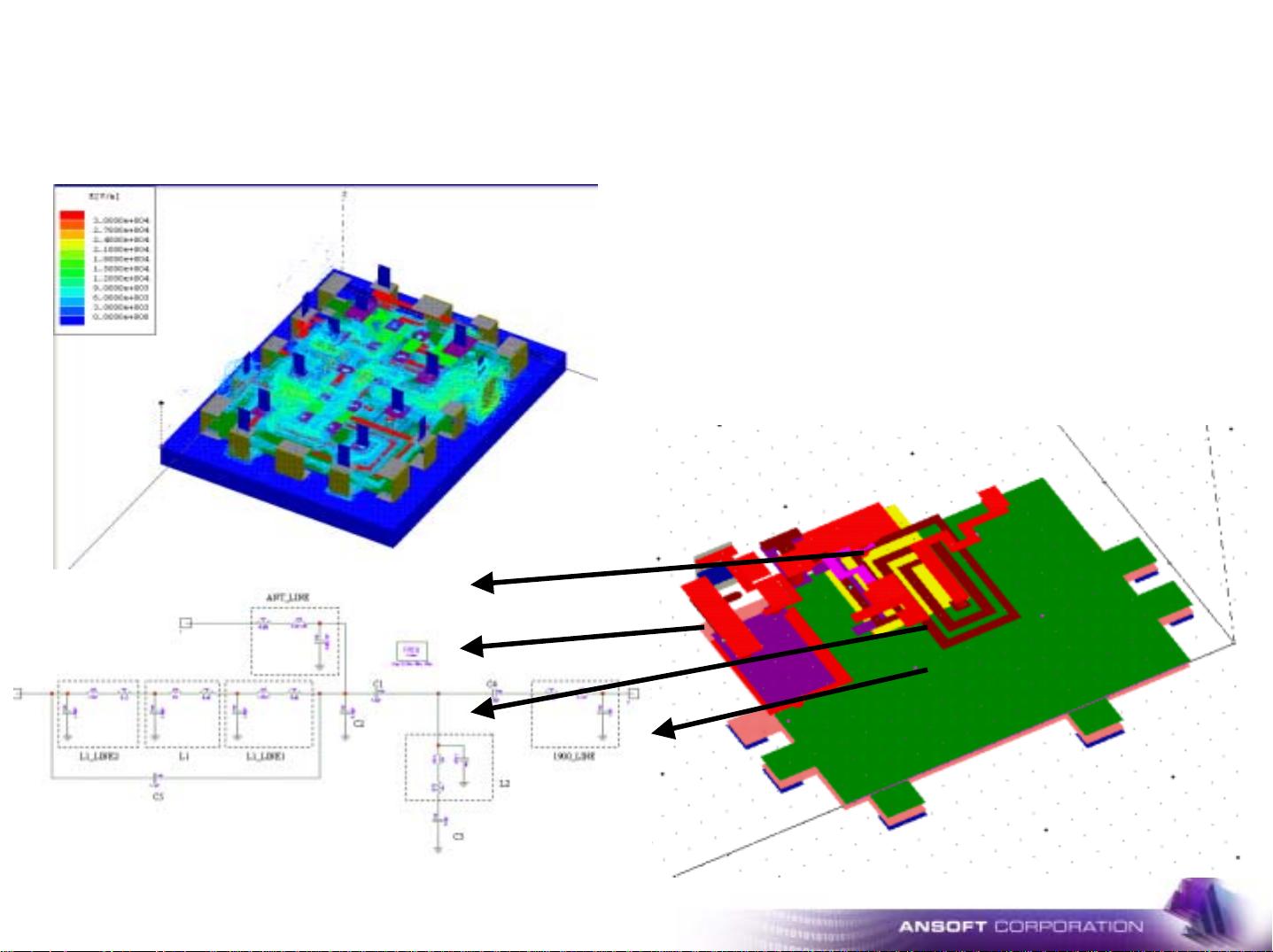

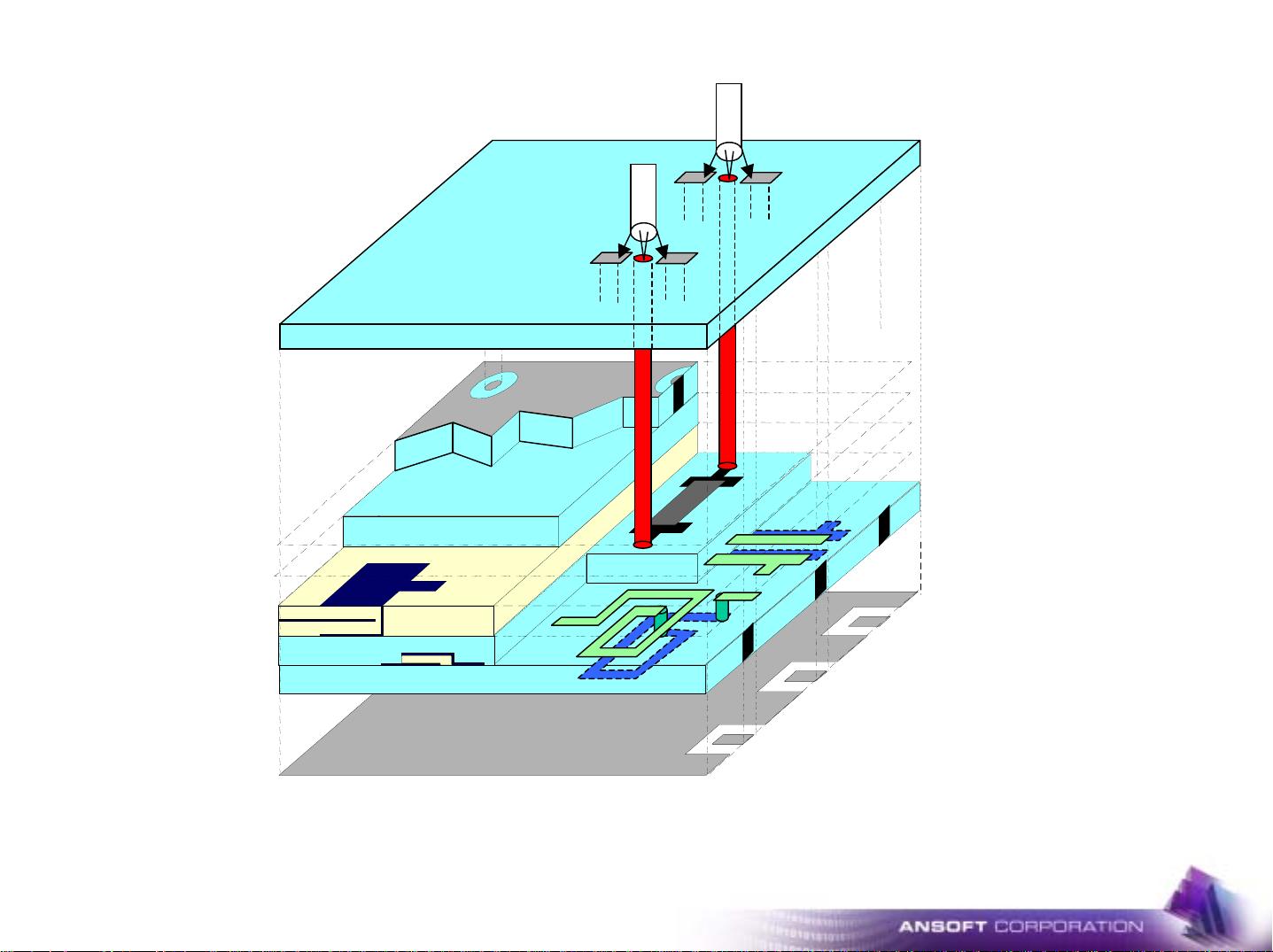

To overcome these challenges, Ansoft Corporation has developed a new LTCC design flow that focuses on automation and optimization. This new approach streamlines the design process, making it more efficient and cost-effective. By using advanced software tools, engineers can now design LTCC components with high performance and low cost in mind.

In this paper, we will explore the new LTCC design flow using a diplexer example. We will also compare measured vs. simulated results, courtesy of Soshin Electric, to highlight the effectiveness of this new approach. By automating and optimizing the design process, engineers can achieve faster time-to-market and lower manufacturing costs.

In conclusion, automating and optimizing LTCC design is crucial for achieving high performance and low cost in electronic devices. By using advanced software tools and streamlined processes, engineers can now design LTCC components with greater efficiency and accuracy. This new approach will revolutionize the way LTCC components are designed and manufactured, leading to innovation and cost savings in the electronics industry.

2023-02-04 上传

2021-01-19 上传

2014-07-14 上传

2023-12-30 上传

2023-06-10 上传

2024-02-28 上传

芯片SIPI设计

- 粉丝: 791

- 资源: 21

最新资源

- 新型智能电加热器:触摸感应与自动温控技术

- 社区物流信息管理系统的毕业设计实现

- VB门诊管理系统设计与实现(附论文与源代码)

- 剪叉式高空作业平台稳定性研究与创新设计

- DAMA CDGA考试必备:真题模拟及章节重点解析

- TaskExplorer:全新升级的系统监控与任务管理工具

- 新型碎纸机进纸间隙调整技术解析

- 有腿移动机器人动作教学与技术存储介质的研究

- 基于遗传算法优化的RBF神经网络分析工具

- Visual Basic入门教程完整版PDF下载

- 海洋岸滩保洁与垃圾清运服务招标文件公示

- 触摸屏测量仪器与粘度测定方法

- PSO多目标优化问题求解代码详解

- 有机硅组合物及差异剥离纸或膜技术分析

- Win10快速关机技巧:去除关机阻止功能

- 创新打印机设计:速释打印头与压纸辊安装拆卸便捷性