"单片机控制管式电阻炉温度:设计与实现"

56 浏览量

更新于2024-03-14

收藏 1.34MB DOC 举报

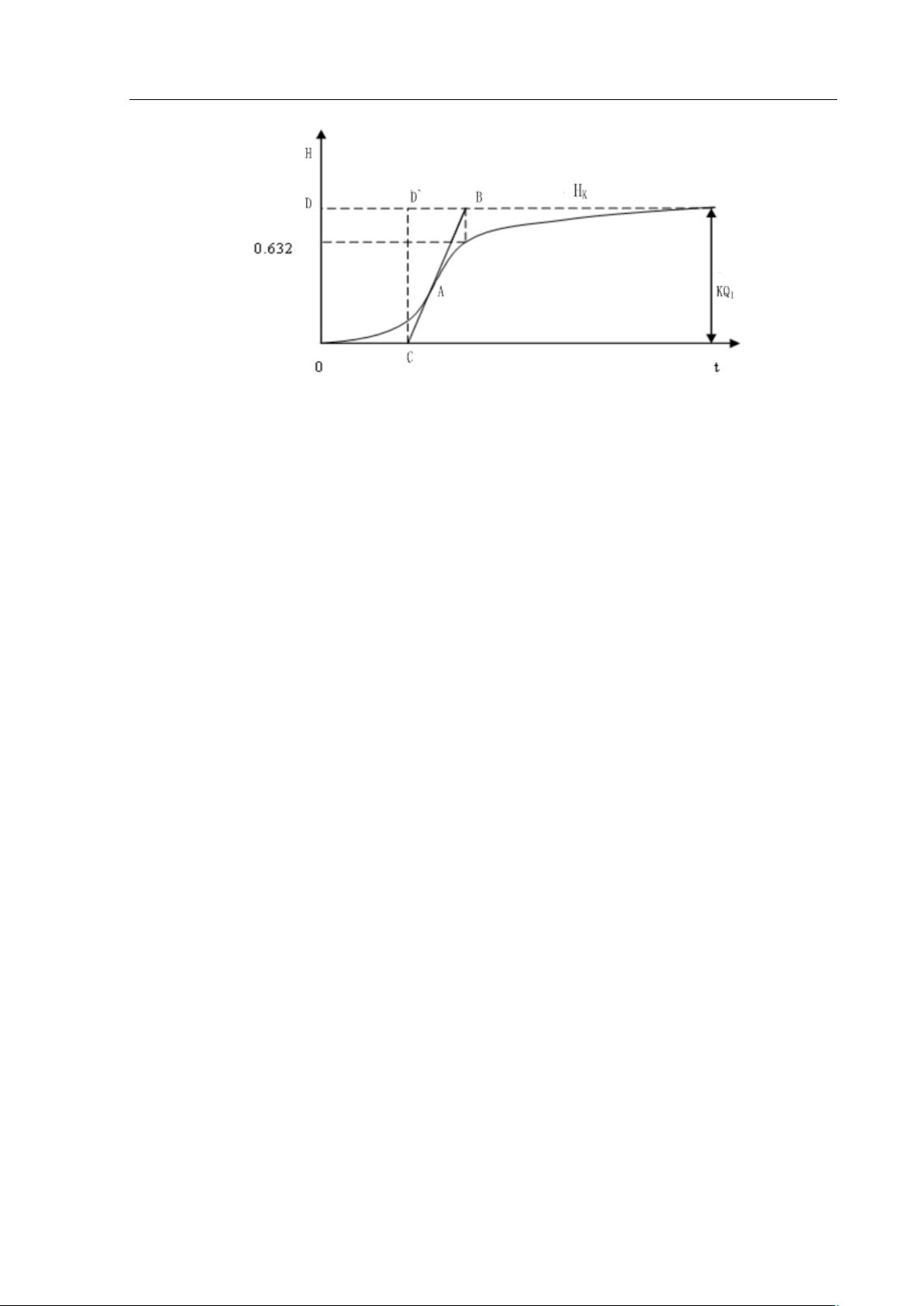

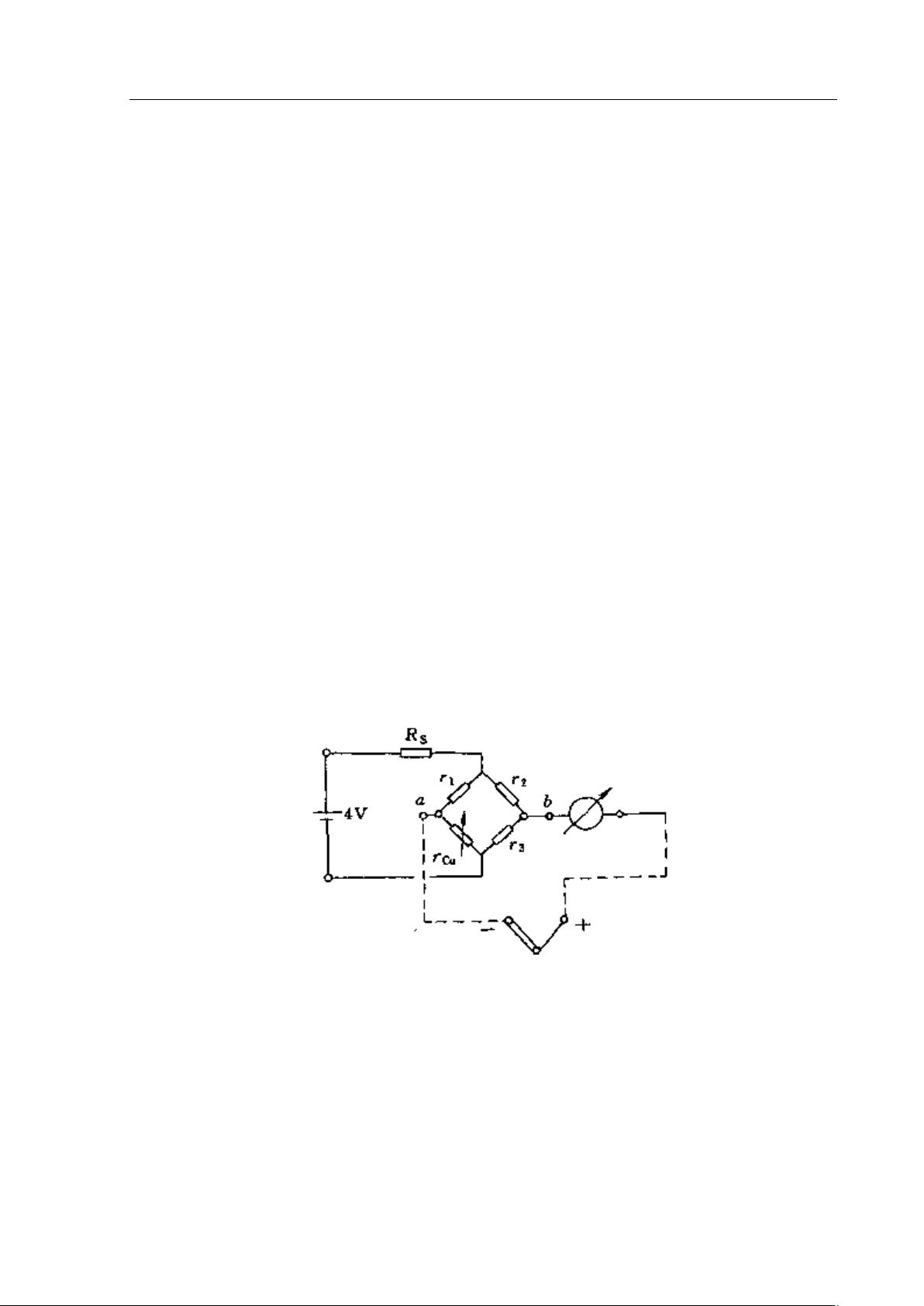

This paper focuses on the temperature control of the commonly used tubular resistance furnace in laboratories. In order to achieve temperature control of the resistance furnace, it is necessary to understand the characteristics of the controlled object. Therefore, the entire process, test plan, and treatment method of the temperature characteristic test of the resistance furnace are introduced. Then, based on the characteristics of the resistance furnace and utilizing the existing equipment in the laboratory, a single closed-loop negative feedback control system is proposed using the DDZ-III instrument combination. The temperature of the resistance furnace is controlled by adjusting the proportional coefficient PK, integral coefficient IK, and derivative coefficient DK of the PID controller. The main steps of designing the temperature control system for the tubular resistance furnace are: firstly, studying the temperature characteristics of the tubular resistance furnace. Secondly, applying a certain chip to assemble the hardware circuit. Thirdly, programming in C51 language. The program is able to simulate the furnace temperature, display intermediate variables, and so on.

Overall, this design provides a practical solution for controlling the temperature of a tubular resistance furnace using a microcontroller unit. It involves conducting tests to understand the characteristics of the furnace, designing hardware circuits, and programming the microcontroller to achieve the desired temperature control. The PID parameters are tuned accordingly to ensure accurate and stable temperature regulation. This design is a valuable contribution to the field of temperature control systems and can be implemented in various laboratory settings for efficient and precise control of the resistance furnace temperature.

2021-10-11 上传

2023-07-08 上传

2023-06-28 上传

2021-09-18 上传

黑色的迷迭香

- 粉丝: 786

- 资源: 4万+

最新资源

- C语言数组操作:高度检查器编程实践

- 基于Swift开发的嘉定单车LBS iOS应用项目解析

- 钗头凤声乐表演的二度创作分析报告

- 分布式数据库特训营全套教程资料

- JavaScript开发者Robert Bindar的博客平台

- MATLAB投影寻踪代码教程及文件解压缩指南

- HTML5拖放实现的RPSLS游戏教程

- HT://Dig引擎接口,Ampoliros开源模块应用

- 全面探测服务器性能与PHP环境的iprober PHP探针v0.024

- 新版提醒应用v2:基于MongoDB的数据存储

- 《我的世界》东方大陆1.12.2材质包深度体验

- Hypercore Promisifier: JavaScript中的回调转换为Promise包装器

- 探索开源项目Artifice:Slyme脚本与技巧游戏

- Matlab机器人学习代码解析与笔记分享

- 查尔默斯大学计算物理作业HP2解析

- GitHub问题管理新工具:GIRA-crx插件介绍