ISA 95.00.01 CDV3 2008 ISA – 19 –

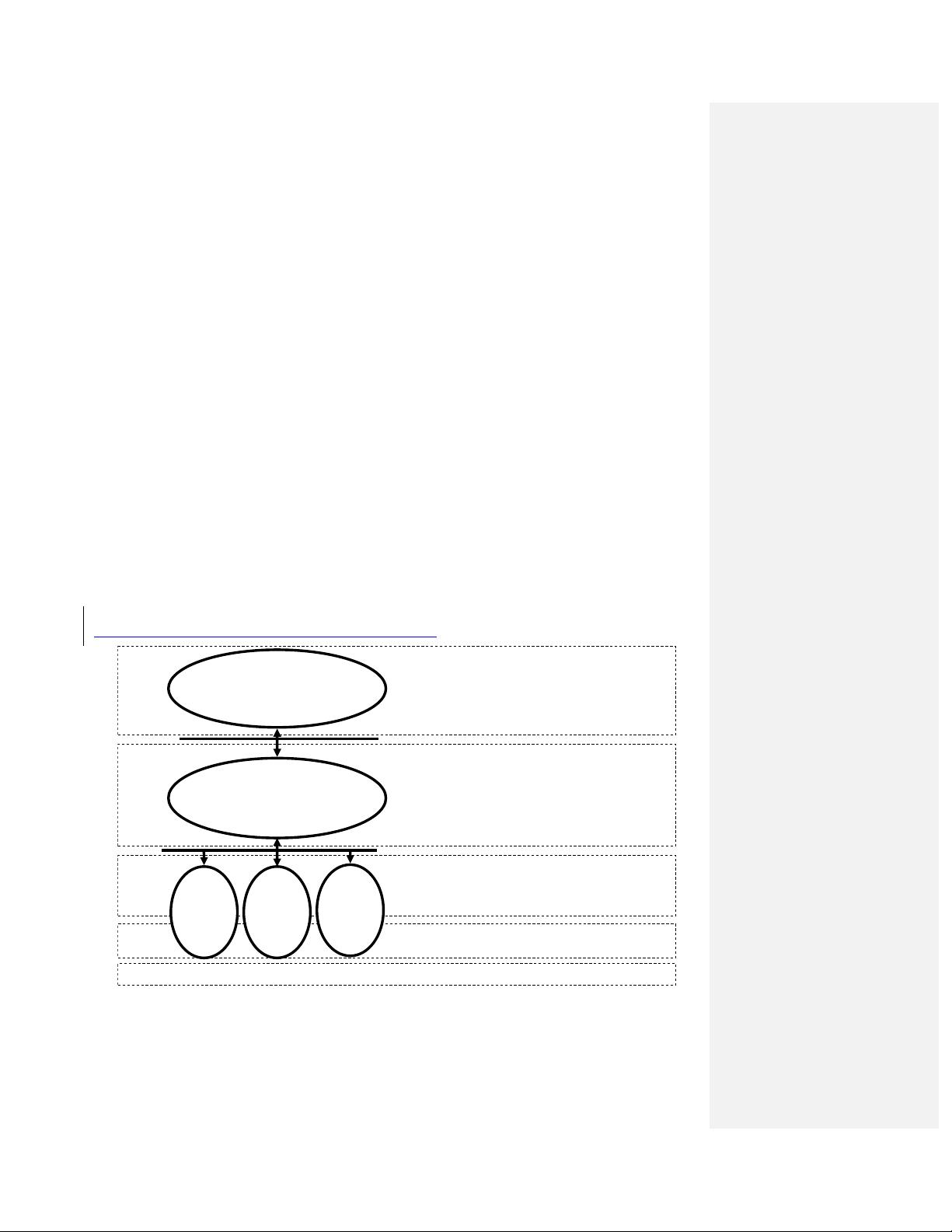

Levels 2, 1, and 0 present the cell or line supervision functions, operations functions, and

process control functions and are not addressed in this standard. The discussion and labeling of

levels is based on a historical description, further described in Annex G. Level 0 indicates the

process, usually the manufacturing or production process. Level 1 indicates manual sensing,

sensors, and actuators used to monitor and manipulate the process. Level 2 indicates the control

activities, either manual or automated, that keeps the process stable or under control. There are

several different models for the functions at these levels based on the actual production strategy

used.

For purposes of this standard the terminology Manufacturing Operations Management (MOM)

defines the Level 3 activities, and Manufacturing Operations and Control (MO&C) define Level 1,

2, and 3 activities. The standard assumes all activities not explicitly presented as part of the

MO&C domain to be part of the enterprise domain.

5.2.2 Criteria for inclusion in manufacturing operations and control domain

The criterion for defining the activities to be included as a Level 3, 2, or 1 activity shall be that

the activity is directly involved in manufacturing and includes information about personnel,

equipment, or material and meets any of the following conditions.

a) The activity is critical to plant safety.

b) The activity is critical to plant reliability.

c) The activity is critical to plant efficiency.

NOTE 1 Absolute plant efficiencies may be dependent upon factors that are outside the control of a facility

(MRP schedules, product mixes, etc.). These activities are not part of Level 3, 2, or 1.

d) The activity is critical to product quality.

e) The activity is critical to maintaining regulatory compliance.

EXAMPLE Maintaining regional, government and other agency compliance related to products and production.

NOTE 2 This includes such factors as safety, environmental and cGMP (current good manufacturing

practices) compliance.

NOTE 3 There are other criteria such as company policy and organizational structure, or the nature of the

operations that could expand the scope of manufacturing operations management. See Annex A.

NOTE 4 Such activities as personnel management of salaries and job titles may be important for running a

manufacturing business, but they are not considered part of manufacturing operations management.

5.2.3 Level 4

Level 4 activities typically include

a) collecting and maintaining raw material and spare parts usage and available inventory, and

providing data for purchase of raw material and spare parts;

b) collecting and maintaining overall energy use and available inventory and providing data for

purchase of energy source;

c) collecting and maintaining overall goods in process and production inventory files;

d) collecting and maintaining quality control files as they relate to customer requirements;

e) collecting and maintaining machinery and equipment use and life history files necessary for

preventive and predictive maintenance planning;

f) collecting and maintaining manpower use data for transmittal to personnel and accounting;

g) establishing the basic plant production schedule;