December 10, 2010 / Vol. 8, No. 12 / CHINESE OPTICS LETTERS 1199

Modeling of silicon-nanocrystal formation in amorphous

silicon/silicon dioxide multilayer structure

Keyong Chen (]]]), Xue Feng (¾¾¾ ÈÈÈ)

∗

, and Yidong Huang (ÀÀÀ)

State Key Laboratory of Integrated Optoelectronics, Department of Electronic Engineering,

Tsinghua University, Beijing 100084, China

∗

E-mail: x-feng@tsinghua.edu.cn

Received August 5, 2010

The formation process of silicon-nanocrystals (Si-NCs) in the amorphous silicon/silicon dioxide (a-Si/SiO

2

)

multilayer structure during thermal annealing is theoretically studied with a modified model based on the

Gibbs free energy variation. In this model, the concept of average effective interfacial free energy variation

is introdu ced and the whole formation process consisting of nucleation and subsequent growth is considered.

The calculating results indicate that there is a lower limit of the silicon layer thickness for forming Si-NCs

in a-Si/SiO

2

multilayer, and the oxide interfaces cannot constrain their lateral growth. Furthermore, by

comparing the results for a-Si/SiO

2

and a-Si/SiN

x

multilayers, it is found that the constraint on the crystal

growth from the d ielectric interfaces depends on the difference between interfacial free energies.

OCIS codes: 310.0310, 310.6805.

doi: 10.3788/COL20100812.1199.

Efficient silicon-based lig ht s ource is one of the most pop-

ular topics in the studies on silicon (Si) photonics that

has attracted many attentions due to its compatibility

with existing semiconductor fabrication techniques. For

this topic, various approaches have b een explored, such

as porous Si

[1,2]

and Si nanocrystals (Si-NCs) in bulk Si-

rich compounds

[3−5]

and multilayers

[6,7]

. Among them,

Si-NCs are holding the a ttention for their strong quan-

tum confinement effects with stable optical properties,

especially when multilayer structure is consider e d as a

method to independently regulate the size and density

of Si-NCs, and improve light emission with substantially

lower driving voltage

[6]

. Nevertheless, compared with

that in bulk Si-rich compounds

[8]

, the formation of Si-

NCs in ultrathin amorphous Si (a-Si) layers covered with

thin dielectric layers, such as SiO

2

and Si

3

N

4

, i.e., a-Si

multilayers, has not been widely studied. The existing

theories

[9,10]

cannot well clarify the whole formation pr o-

cess of Si-NCs in multilayers by modeling nucleation and

subsequent growth separately. In this letter, for bet-

ter understanding and control of the Si-NC formation,

a modified mo del is developed to unify the formation

process based on the Gibbs free energy variatio n. Ac-

cording to the calculations using the proposed model, a

lower limit for the a-Si layer thickness and incapability

of constraint on the lateral growth of Si-NCs from the

oxide interfaces are discovered in a-Si/SiO

2

multilayers.

Furthermore, the model could be readily applied to es-

timate the differences between interfacial free energies,

which correspond to different dielectric materials. By

comparing the results of a-Si/SiO

2

and a-Si/SiN

x

multi-

layers, we find that the constraint on the Si-NC growth

from the dielectric interfaces depends on the difference

between interfacial free energies.

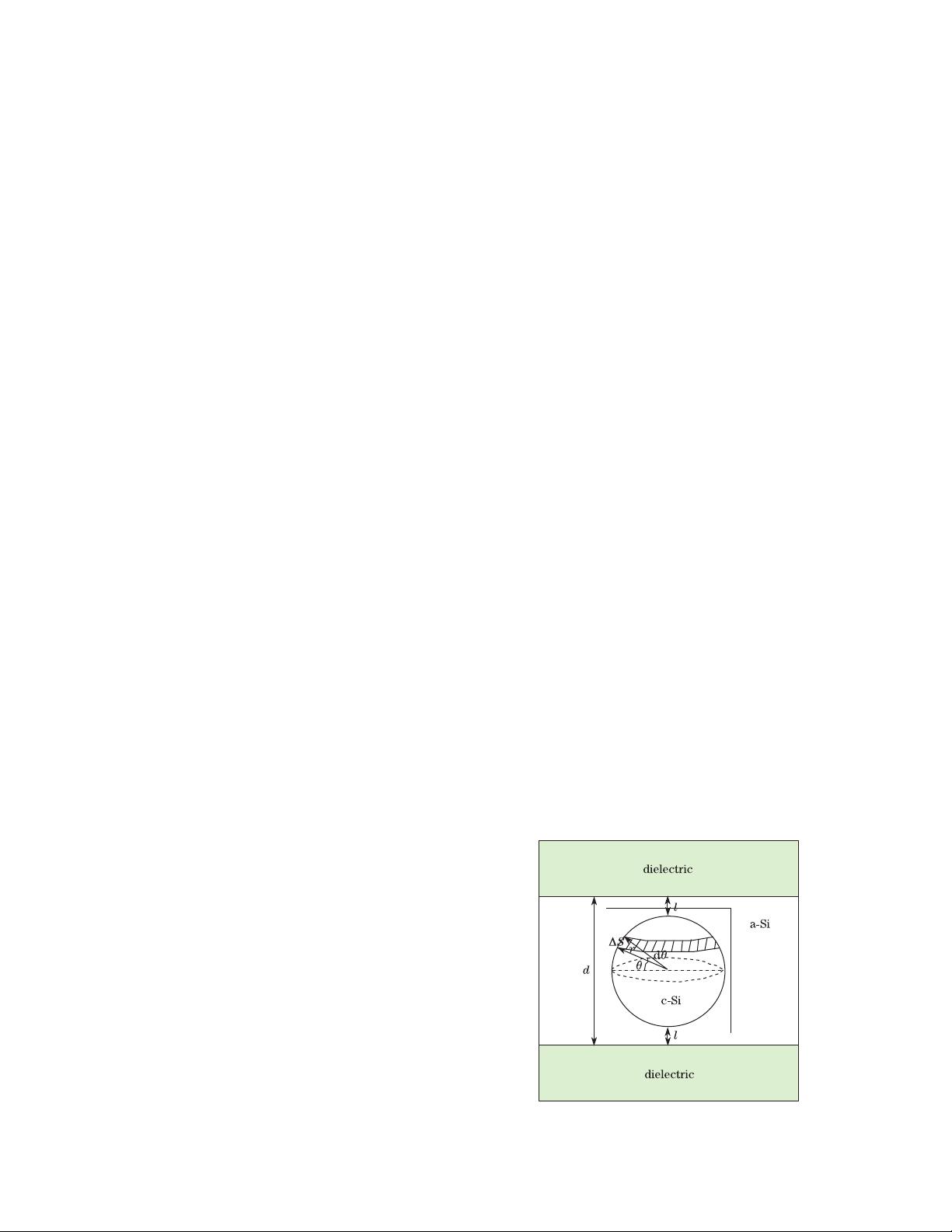

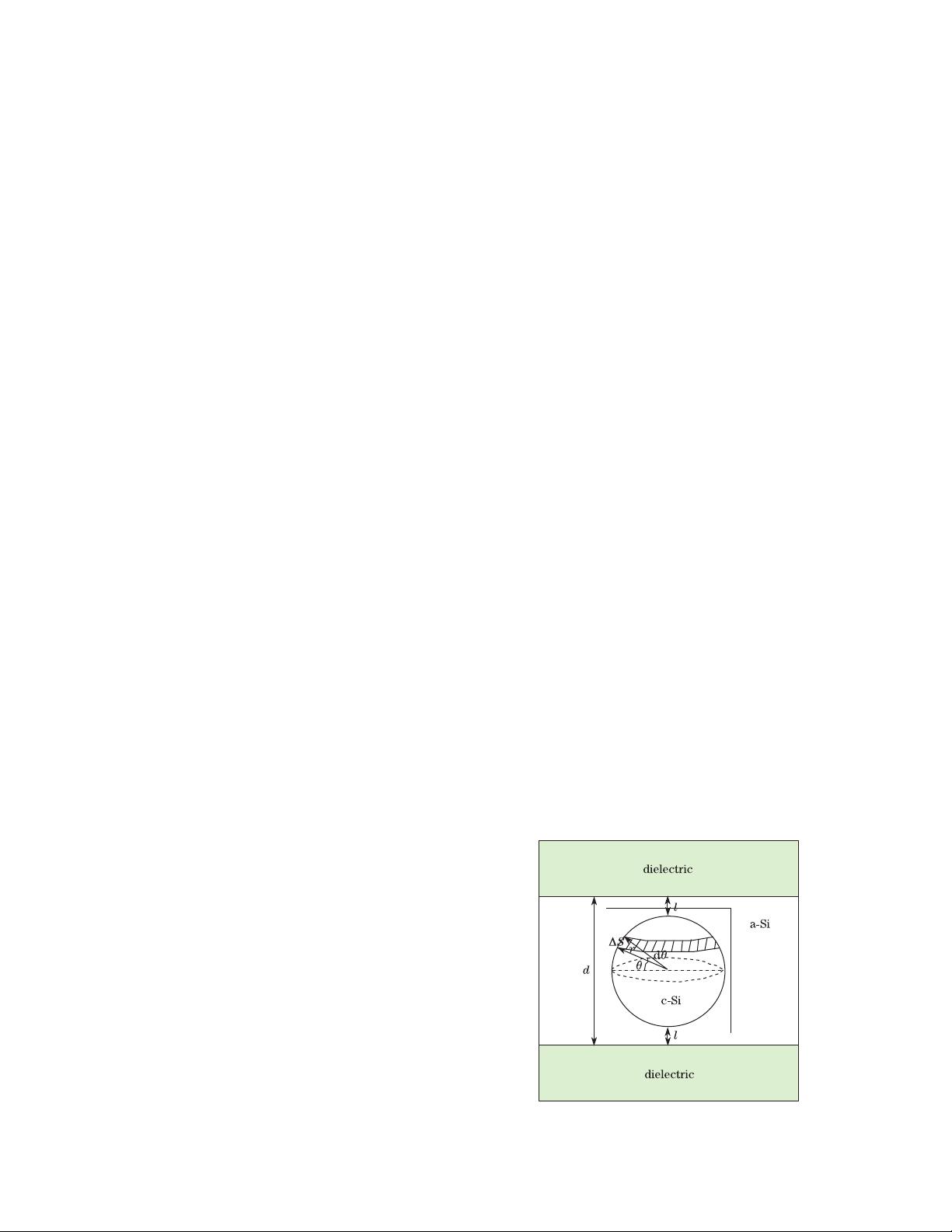

In genera l, the formation of Si-NCs includes nucleation

and the following growth, induced either by furna ce

annealing or pulsed laser

[11]

. Nucleation occurs homoge-

neously in the interior of the uniform amorphous phase

or heterogeneously at preferential sites such as impuri-

ties, interfaces, and defects. After nucleation, Si-NCs

would grow up with sufficient external thermal energy.

Here, we divide the whole formation process into two

successive stages, i.e., pre-touch and post-touch of the

dielectric interfaces. The multilayer is simplified as an

a-Si/dielectric sandwich structure as shown in Figs. 1

and 2. In the pre-touch stage, a Si-NC is assumed to

nucleate symmetrically in the middle of the a-Si layer

with spherical shape with radius r. As in Ref. [9],

spacing l is introduced to s e parate the cr ystal nucleus

from the dielectric interfaces. When the Si-NC keeps

growing up and intersects the top and bottom inter-

faces, the p ost-touch stage will begin. However, it will

be shap e d like a drum with lateral diameter beyond the

layer thickness d. Moreover, we define γ

ac

as the inter-

facial free energy per unit area between the a-Si phase

and the crystalline Si (c-Si) phase, γ

dc

as that between

the dielectric material and the c-Si phas e , and γ

da

as

that between the dielectric material and the a- Si phase.

According to the deductions in Ref. [9], we can then

achieve the effective interfacial free energies γ

eff

dc

and γ

eff

da

:

Fig. 1. Schematic diagram of the Si-NC in the pre-touch

stage.

1671-7694/2010/121199-04

c

2010 Chinese Optics Letters