unripe, mid-ripe and ripe strawberries. Wendel et al. (2018)

applied a hyperspectral camera and navigation system

mounted to a ground vehicle to estimate and map mango

maturity in an orchard, and promising results were determi-

nation coefficient of cross-validation (R

2

cv

) of 0.64 and root

mean square error of cross-validation (RMSECV) of 1.08 %w/w

for dry matter content prediction in fruit on tree. However, to

the best of our knowledge, few researches have been reported

respect to in-field and non-destructive determination of in-

ternal quality and ripeness stages of peaches using hyper-

spectral imaging.

Therefore, the objective of this work was to investigate the

feasibility of portable hyperspectral imager for in-field deter-

mining the internal quality and ripeness stages of Feicheng

peach combined with chemometrics. To this end, hyper-

spectral images were in-field captured from mid-ripe and ripe

Feicheng peaches, and regression models were established

and compared with respect to their monitoring performance

for quality attributes.

2. Materials and methods

2.1. Sample preparation

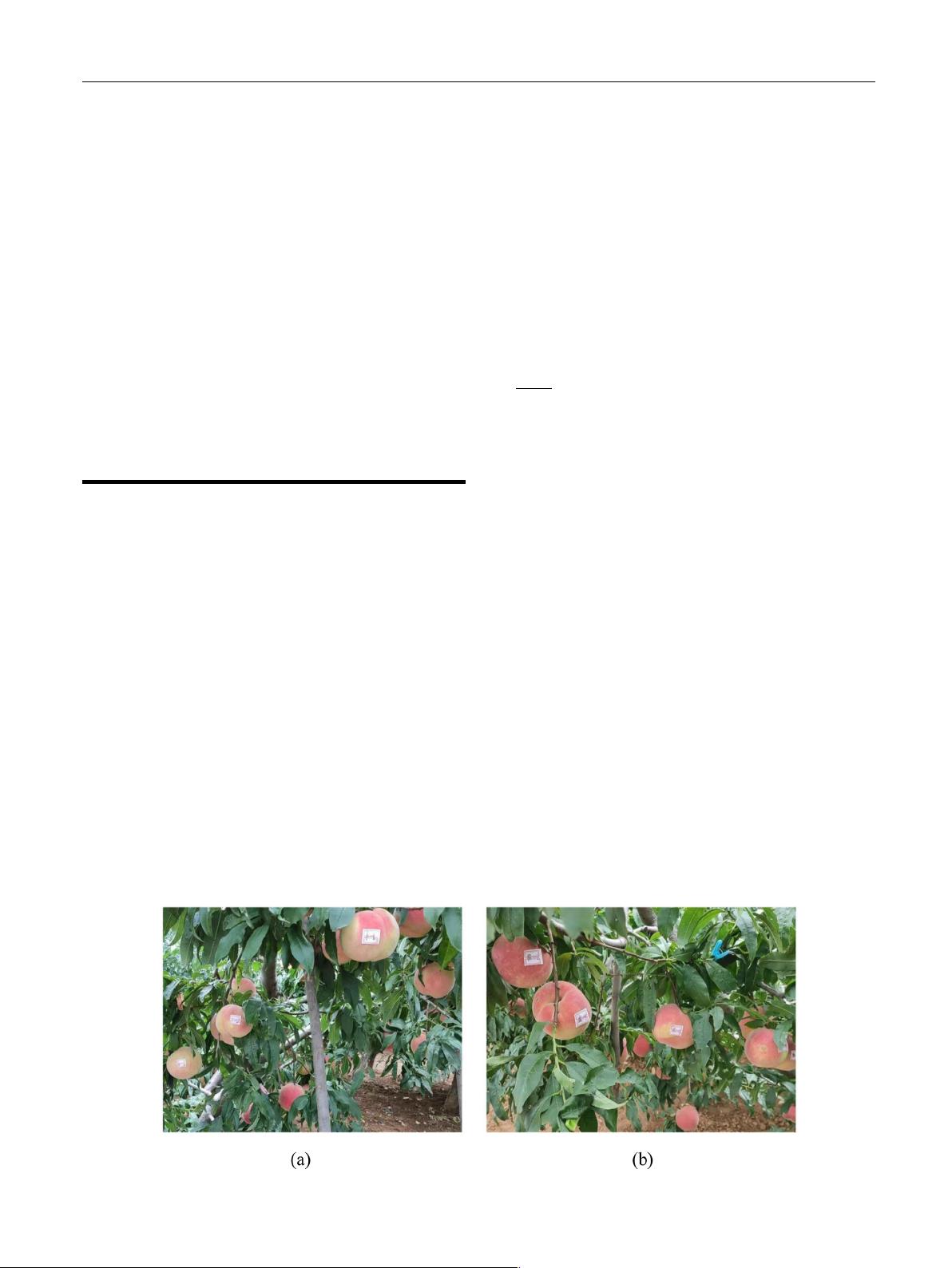

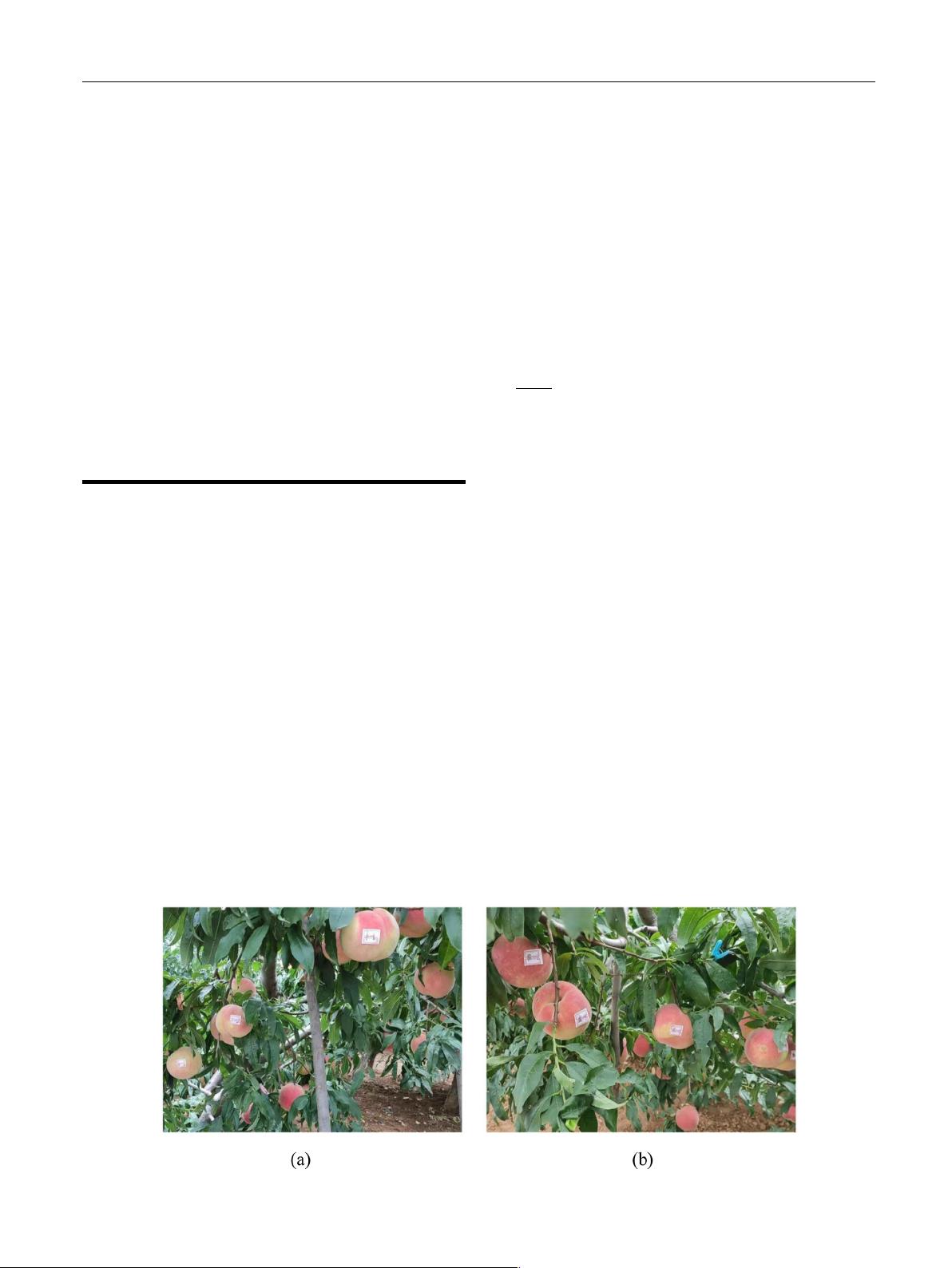

Field sampling was conducted at a commercial orchard in

Feicheng City, Shandong, China (36.2003

N, 117.0876

E) on

September 14th, 2019. Mid-ripe and ripe Feicheng peach on 25

trees were randomly selected for spectral acquisition by the

experienced growers, and tagged afterwards to ensured that a

specific internal quality measurement was related to a specific

fruit in the image (Fig. 1). Then Feicheng peaches were picked,

wrapped and placed in a cooler and transported to the labo-

ratory on the same day. In this study, 80 mid-ripe and 80 ripe

fruits without leaves barrier and skin defects were collected

for quality monitoring of Feicheng peach.

2.2. Hyperspectral image acquisition

Figure 2 showed in-field image acquisition and processing. A

portable hyperspectral imager (GaiaField-V10E, Jiangsu Dualix

Spectral Imaging Technology Co., Ltd, Wuxi, Jiangsu, China),

mounted on a tripod, was employed to capture the Feicheng

peach images with a size of 1394 1040 pixels. It had a

spectral range of 400e1000 nm, a spectral resolution of 2.8 nm

and a field of view of 22

. To obtain a clear and undistorted

image, exposure time was set to 15.2 ms by scanning the

whole rectangular Teflon plate (Jiangsu Dualix Spectral Im-

aging Technology Co., Ltd, Wuxi, Jiangsu, China) placed on the

tripod. Hyperspectral images were acquired in natural illu-

mination under cloudy conditions from 11:00 am and 2:00 pm,

and the distance was 1.5 m between the lens and the pe-

riphery of tree scenes.

The raw hyperspectral image I

r

was calibrated to reduce

the effects of the uneven illumination and dark current noise

on the image using the following equation:

I

c

¼

I

r

I

d

I

w

I

d

(1)

where, I

c

was the calibrated image; I

d

was the dark reference

image, obtained by covering the lens with an opaque cap; I

w

was the white reference image, acquired from scanning the

rectangular Teflon plate used above. It was mounted to the

tripod and placed in the same scenes with fruits. To correctly

acquire hyperspectral images, for some obscured peaches, the

leaves were push aside and fixed with clips to expose the fruit.

A64 64 pixel region of interest (ROI) was extracted manually

from each fruit using software ENVI5.1 (Environment for

Visualizing Images, Research Systems Inc., Boulder, CO, USA),

covering major part of scanned fruit surface. The raw average

reflectance was calculated from all the pixels in ROI.

2.3. Measurement of internal quality attributes

Following in-field image acquisition, SSC and firmness of

Feicheng peach were measured in the postharvest engineer-

ing laboratory at Shandong Agricultural University, Tai'an,

Shandong, China. Measurements were performed at upper,

middle and lower fruit parts after peeling 1 cm

2

of a skin.

Firmness was first measured by a firmness metre (GY-1,

Thorpe Ltd, Zhejiang, China). A 3.5 mm probe punctured into

the peach about 10 mm at the speed of 0.5 mm/s, and firmness

was averaged at the three measured sections. Then, a digital

refractometer (PAL-1, Atago Co, Tokyo, Japan) was used to

Fig. 1 e Mid-ripe (a) and ripe (b) Feicheng peach on trees.

biosystems engineering 212 (2021) 115e125 117