COL 9(9), 093102(2011) CHINESE OPTICS LETTERS Septemb er 10, 2011

Effect of native defects and laser-induced defects on

multi-shot laser-induced damage in multilayer mirrors

Ying Wang (王王王 营营营)

1,2∗

, Yuanan Zhao (赵赵赵元元元安安安)

1

, Jianda Shao (邵邵邵建建建达达达)

1

, and Zhengxiu Fan (范范范正正正修修修)

1

1

Key Laboratory of Materials for High Power Lasers, Shanghai Institute of Optics and Fine Mechanics,

Chinese Academy of Science, Shanghai 201800, China

2

Graduate University of Chinese Academy of Sciences, Beijing 100049, China

∗

Corresp onding author: wangying@siom.ac.cn

Received February 17, 2011; accepted April 14, 2011; posted online July 11, 2011

The roles of laser-induced defects and native defects in multilayer mirrors under multi-shot irradiation

condition are investigated. The HfO

2

/SiO

2

dielectric mirrors are deposited by electron beam evaporation

(EBE). Laser damage testing is carried out on both the 1-on-1 and S-on-1 regimes using 355-nm pulsed

laser at a duration of 8 ns. It is found that the single-shot laser-induced damage threshold (LIDT) is

much higher than the multi-shot LIDT. In the multi-shot mode, the main factor influencing LIDT is the

accumulation of irreversible laser-induced defects and native defects. The surface morphologies of the

samples are observed by optical microscopy. Moreover, the number of laser-induced defects affects the

damage probability of the samples. A correlative model based on critical conduction band (CB) electron

density (ED) is presented to simulate the multi-shot damage behavior.

OCIS codes: 310.0310, 140.3330.

doi: 10.3788/COL201109.093102.

It is widely regarded that multi-shot laser-induced dam-

age threshold (LIDT) in most optical materials decreases

with increasing pulse number because of the accumula-

tion effects

[1−3]

. Recently, many laboratories have inves-

tigated the multi-shot laser-induced damage (LID) of op-

tical materials, such as fused silica

[3]

and KTP crystal

[4]

.

Optical coatings are used very often in high-power laser

systems

[5]

. As a result, the investigation of multi-shot

LID of optical coatings is of high practical importance

for high-power laser applications in recent years

[6]

. In

a previous study, a model was developed to explain the

correlations between the observed multi-shot LIDT and

its dependence on the number of shots at 1 064 nm

[7]

. It

is easier to generate the color center at an intensity be-

low the damage threshold ultraviolet laser light

[8]

. The

damage behavior of 355 nm is much complicated than

that of 1 064 nm. The aim of this letter is to analyze the

accumulation effect on laser damage resistance at 355

nm. The effect of native defects and laser induce defects

on multi-shot LIDT is discussed.

The 355 high reflectivity (HR) coatings were prepared

by electron beam evaporation (EBE). The coating design

of the sample was (HL)

14

H, where H and L stand for the

high-index material (HfO

2

) and the low-index material

(SiO

2

), respectively, with one-quarter wavelength optical

thickness (QWOT).

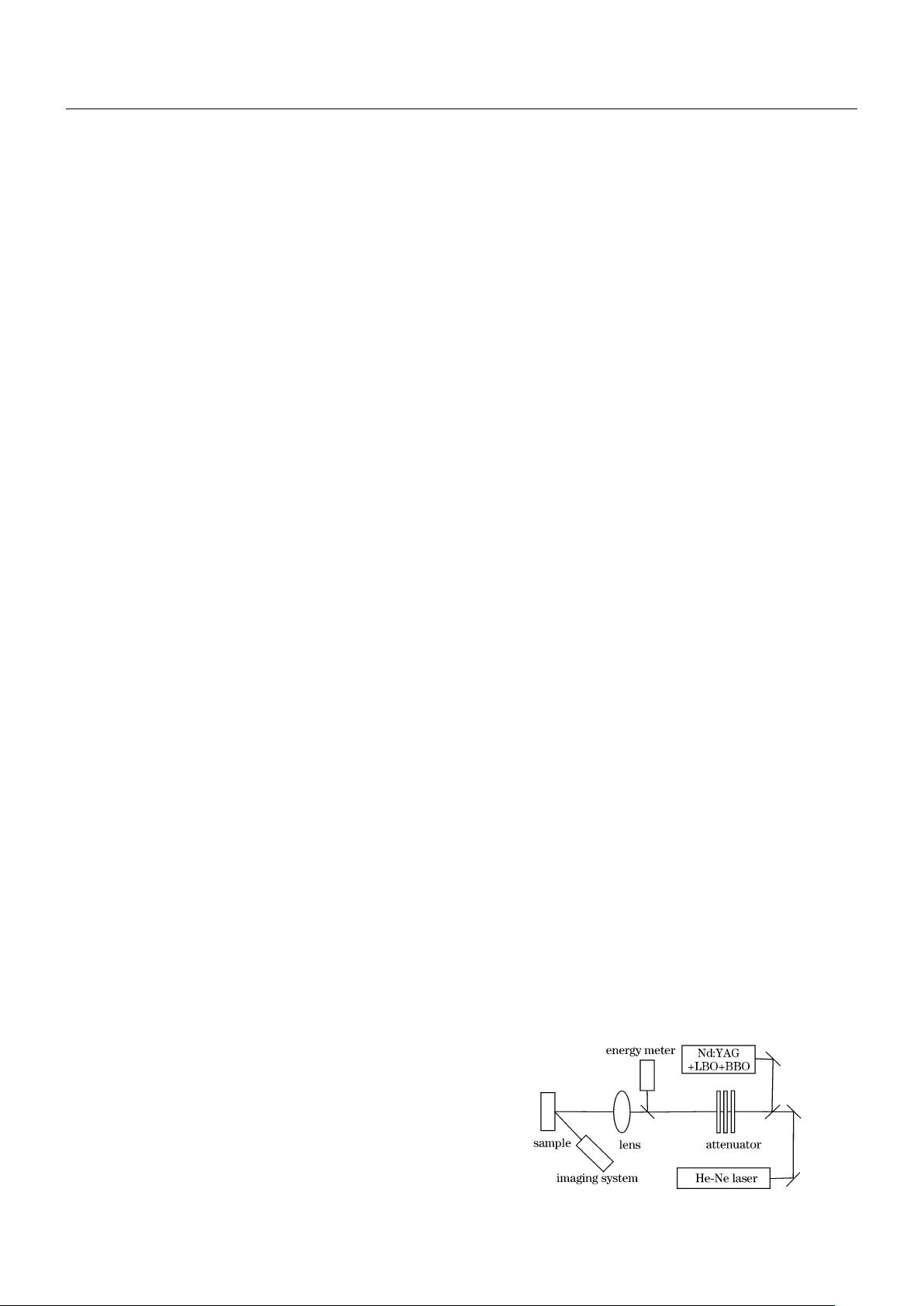

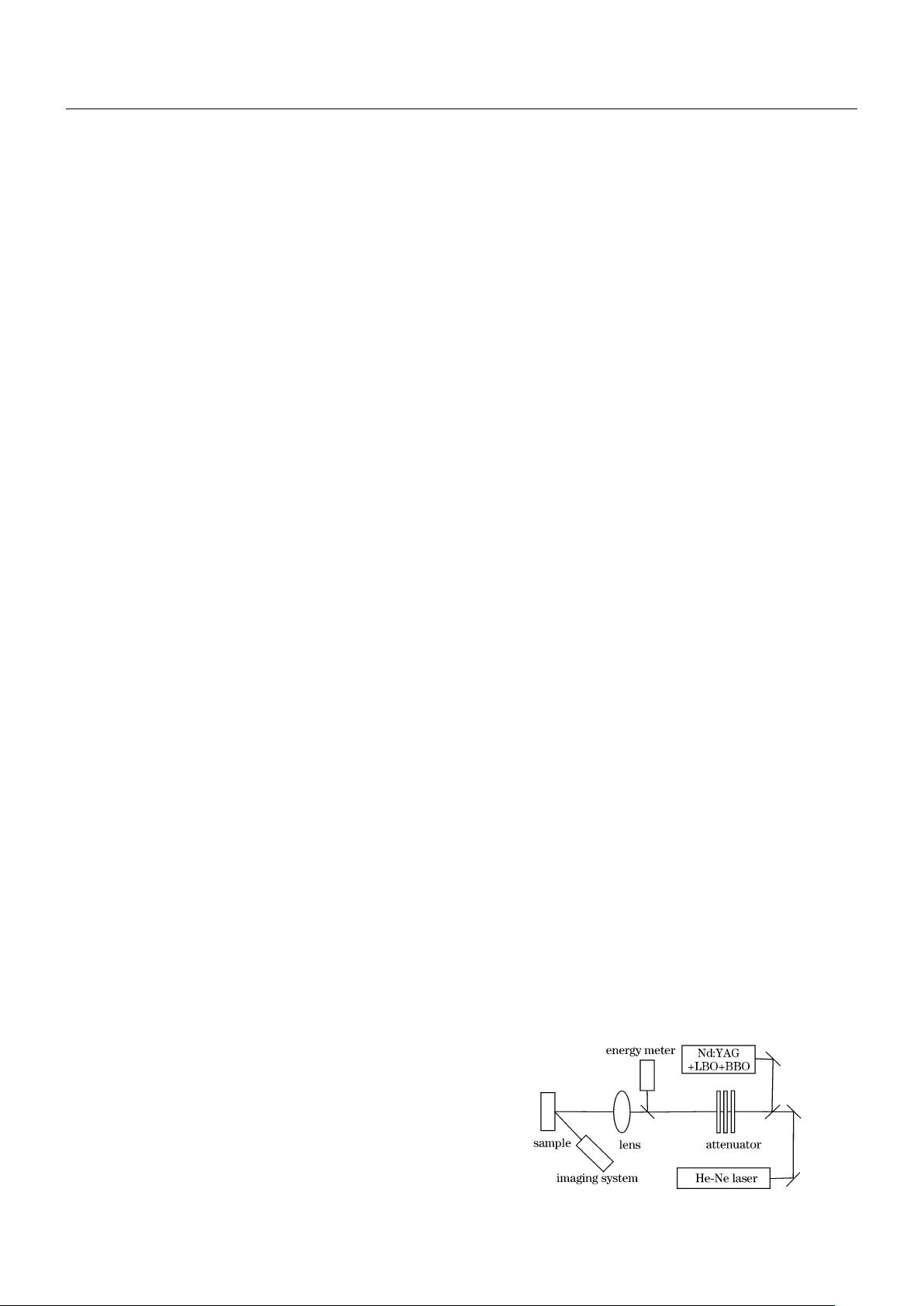

The experimental setup for laser damage is shown

schematically in Fig. 1, in which the Nd:YAG laser sys-

tem is operated at the TEM

00

mode and the pulse width

is 8 ns at 355 nm. The beams were focused to a 1/e

2

height of 380 µm and width of 350 µm. In the S-on-1

test, the sample was tested at the frequency of 5 Hz.

The laser energy that was used to damage the sample

was obtained by the adjustment of the attenuator, and

the pulse energy was measured by an energy meter from

a split-off portion of the beam. The sample was set upon

a two-dimensional precision stage driven by a stepper

motor. The He-Ne laser was used to monitor the test.

Damage onset was detected online by a video microscopy

system.

The S-on-1 test was carried out according to ISO

11254-2

[9]

. In this letter, 1-on-1, 5-on-1, 10-on-1, 20-

on-1, and 100-on-1 LIDTs were tested to understand the

influence of the shot number on the accumulation effects.

Two representations of the damage data can be found

in Fig. 2. The S-on-1 damage probability curves with

S ranging from 1 to 100 are shown in Fig. 2(a). The

0% damage probability is summarized in Fig. 2(b). The

accumulation effects become clear in the two representa-

tions.

The data in Fig. 2(a) show the increase in damage

probability with the number of pulses and a clear de-

crease in the damage threshold with the increase in laser

pulse number. From Fig. 2(b), it can be seen that the

0% damage probability drops monotonically to a mini-

mum value.

The damage morphology of the HR coatings was ac-

cessed by optical microscope. The typical damage mor-

phology information after 1-on-1 and S-on-1 tests are

shown in Fig. 3. All the morphologies clearly permit

that the damages originated from small defects. The

delamination characteristic of optical films can be seen

in the S-on-1 test.

Due to interference effects in film, local intensity en-

hancements exist in the sample coatings. The theoretical

Fig. 1. Experimental setup of laser damage testing.

1671-7694/2011/093102(4) 093102-1

c

° 2011 Chinese Optics Letters