Experimental research of laser-induced periodic surface

structures in a typical liquid by a femtosecond laser

Youwang Hu (胡友旺), Haoming Yue (岳浩铭), Ji’an Duan (段吉安), Cong Wang (王 聪),

Jianying Zhou (周剑英), Yunpeng Lu (鲁云鹏), Kai Yin (银 恺), Xinran Dong (董欣然),

Wenyi Su (苏文毅), and Xiaoyan Sun (孙小燕)*

State Key Laboratory of High Performance and Complex Manufacturing, College of Mechanical and Electrical

Engineering, Central South University, Changsha 410083, China

*Corresponding author: sunxy@csu.edu.cn.

Received August 25, 2016; accepted December 15, 2016; posted online January 12, 2017

A constant elastic alloy is a widely used material with a high elastic modulus and an excellent wave velocity

consistency. Different morphologies on the constant elastic alloy surface are observed through femtosecond laser

irradiation. When the laser average fluence is set to 0.58 J∕cm

2

and 200 laser pulses, with the increasing depth of

distilled water, the period of the laser-induced periodic surface structures (LIPSS) becomes shorter accordingly.

The higher the ethanol concentration is, the more spot-shaped structures will be formed among the surface struc-

tures when the depth of the coverage of ethanol is 2 mm. The period of the LIPSS reaches its maximum when the

concentration of ethanol is 80%.

OCIS codes: 320.2250, 220.4241, 100.0118.

doi: 10.3788/COL201715.021404.

Laser-induced periodic surface structures (LIPSS) are

formed when a femtosecond laser radiates materials

[1]

.It

is generally accepted that these LIPSS are generated by

interaction of the incident laser beam with the surface

electromagnetic wave (SEW). They are usually generated

on surfaces by the excitation of surface plasmon polaritons

(SPPs)

[2]

. The growth of LIPSS remains a point of discus-

sion of many researchers

[2–8]

. Various research reported in

the literature are using ultra-short pulse lasers to generate

periodic structures on a variety of materials such as semi-

conductors

[9,10]

, metals

[11,12]

, and dielectrics

[13]

. The process-

ing parameters of a femtosecond laser include wavelength,

number of pulses, fluences, pulse duration, incident angles,

and polarization. The effects of these para meters have

been investigated on the spatial wavelength and depth

of periodic surface structure of LIPSS

[14]

. Most of the pre-

vious studies on the LIPSS focus on those structures gen-

erated with the assistance of gaseous conditions. In recent

years, some researchers have been studying LIPSS that

are generated with the assistance of various liquids

[15,16]

.

Interactions between the laser and the material in the

liquid are considerably complicated, involving a highly

confined plasma pressure, efficient cooling, enhanced

chemical reactivity, and the generation of elevated tem-

peratures, etc.

[17–19]

. Compared with LIPSS formed in gas-

eous environments, LIPSS fabricated in liquid conditions

is more significant as it has an important application such

as controlling generations of nanostruc ture and synthesis

of nanoparticles.

According to previous research, the spatial wavelength

of LIPSS in an atmospheric environment is generally

longer than that in a liquid

[14]

. Different parameters, such

as pulse width, wave length, fluence, numbers of pulses,

the kind and depth of the liquids, the surfactant, and

the nature of the target material have a great influence

on liquid assisted laser ablation. These parameters can

be taken as controlling during the processes of melting,

evaporation, plasma generation, and generate nanostruc-

tures on the ablated surface

[3]

. However, few researchers

have paid attention to the effect of different depths of

distilled water and different concentrations of ethanol

on LIPSS

[3,14]

.

In this study, a constant elastic alloy was used to study

the effect of the different femtosecond laser average fluen-

ces on the periodic surface structure. Experimental results

show how the depths of distilled water, the laser average

fluence, and the concentration of ethanol influence the

periodical surface structures. It can provide some ways

on how to employ better femtosecond laser parameters

and an ablation medium to control the periodical surface

structures.

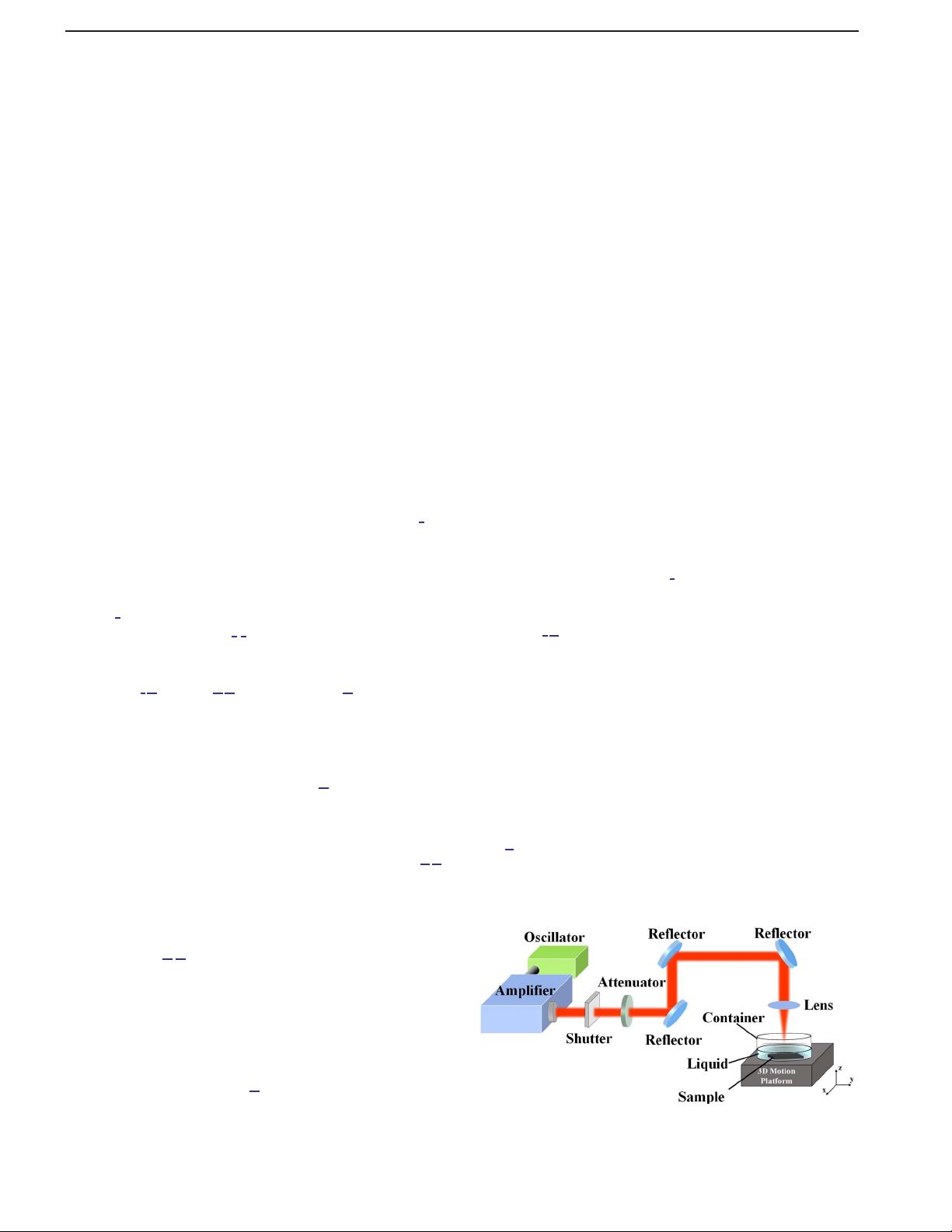

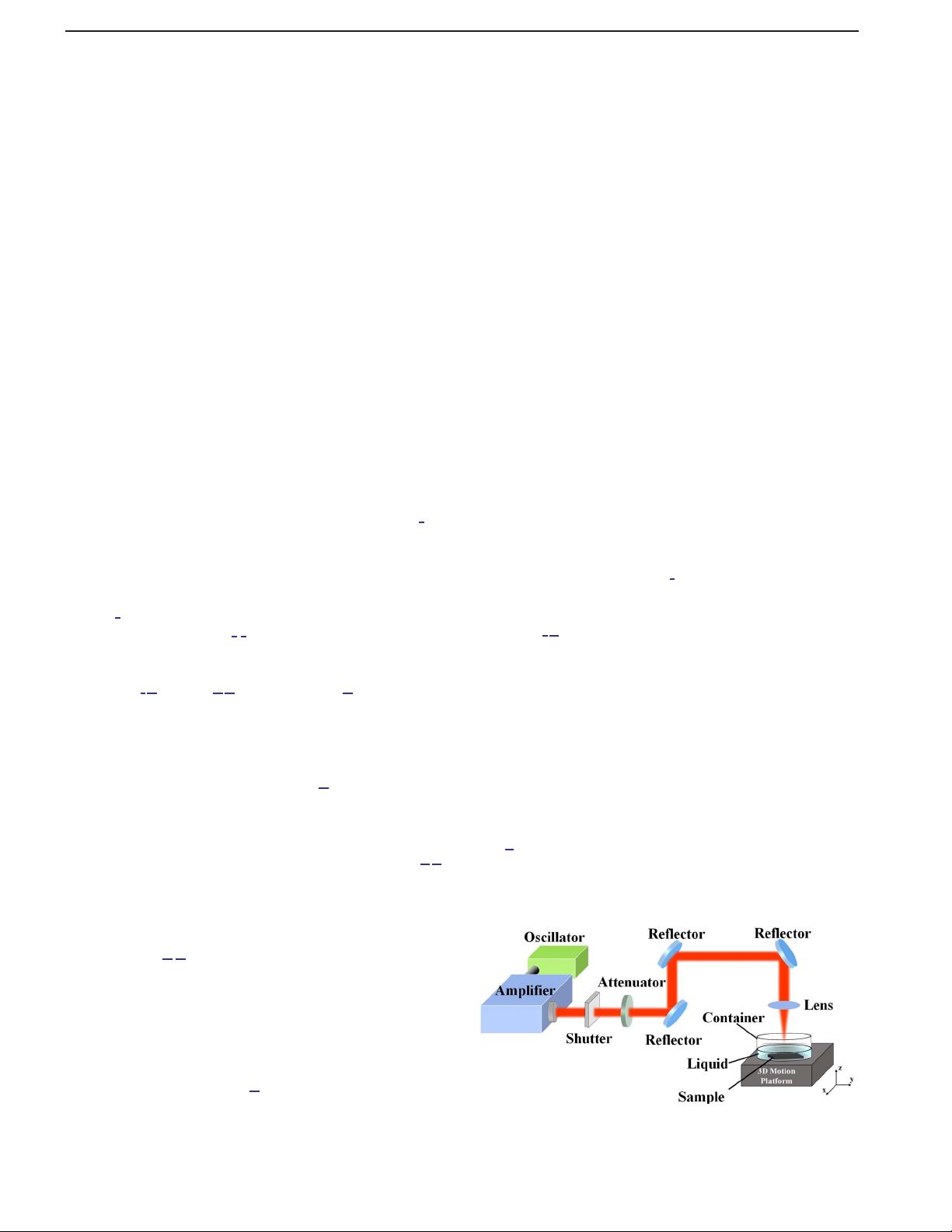

The schematic of the experimental setup is shown in

Fig.

1. A Ti:sapphire solid femtosecond laser from Spectra

Physics Company is employed in these experiments. The

maximum single pulse energy of the laser output by the

Fig. 1. Schematic diagram of the experimental setup.

COL 15(2), 021404(2017) CHINESE OPTICS LETTERS February 10, 2017

1671-7694/2017/021404(5) 021404-1 © 2017 Chinese Optics Letters