"弯管机电气控制系统设计及PLC编程技术应用"

需积分: 6 102 浏览量

更新于2023-12-26

收藏 788KB DOC 举报

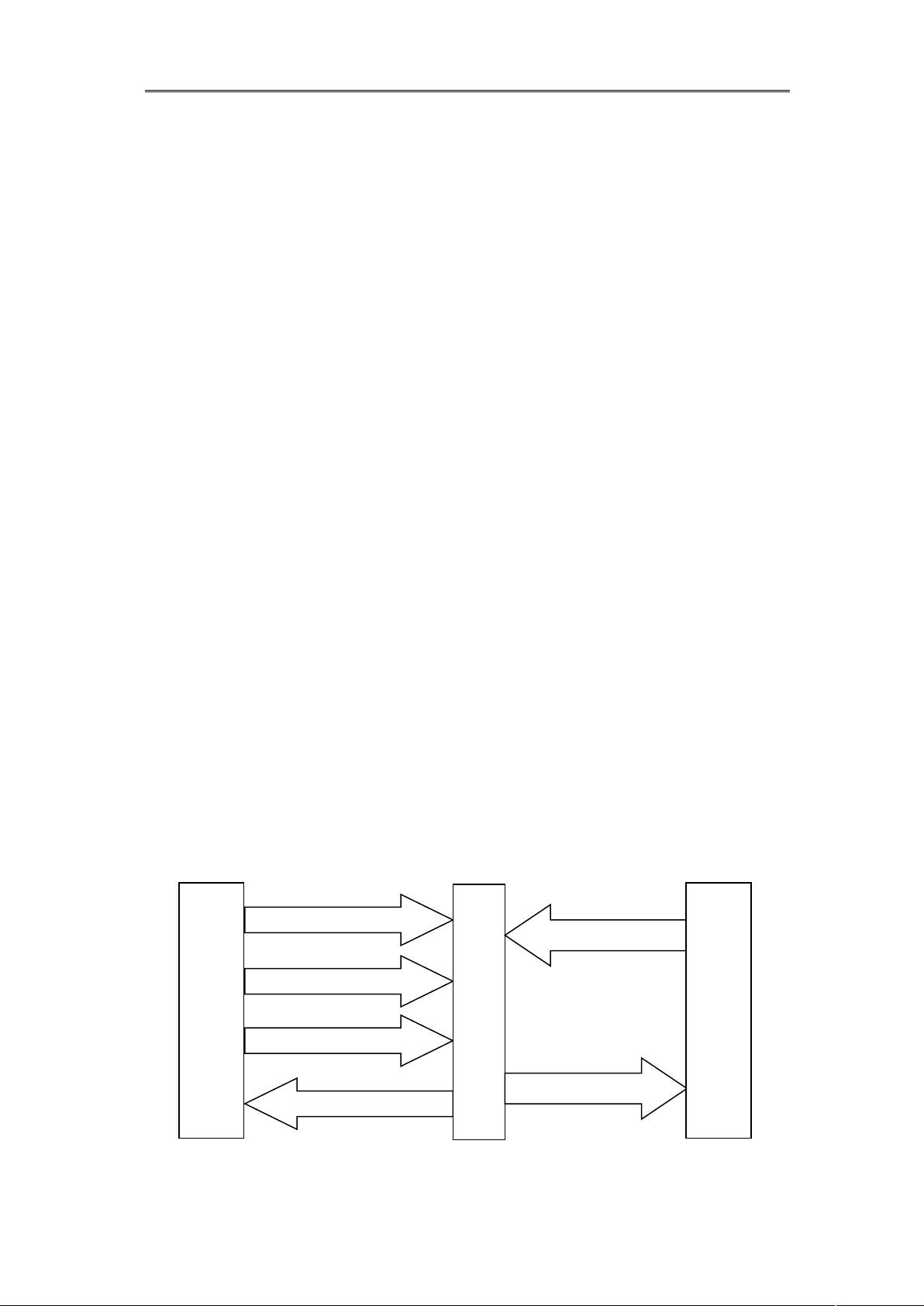

r, the pipe bending machine system provided by the power pipe fittings in Yanshan County, Cangzhou, Hebei, is used as the background for design and writing. The working principle, process flow, and software programming control of the pipe bending machine are introduced in detail. The characteristics and applications of the electrical control system are elaborated. The pipe bending machine is widely used in the petroleum industry and has also been applied in the West-East Gas Pipeline project developed by the country. It can be seen that the pipe bending machine occupies an important position in the machinery industry of my country, and its development also reflects the development of our industry. The modern pipe bending machine is characterized by large diameter and thick arm tube, and we use medium frequency hydraulic heating pipe bending machine to bend it accordingly. By using PLC to control the pipe bending machine and displaying temperature, speed, etc. on the upper computer, the quality and efficiency of the pipe bending can be better controlled. This paper introduces the working principle and simple process flow of the pipe bending machine, PLC structure, internal principle, and performance, as well as the internal structure of S7-200 and the use of it to write the control program for the pipe bending machine. The use of the S7-200 programmable controller is safer, more reliable, durable, intuitive, and flexible in application than relays and contactors in harsh environments. Finally, the STEP-7 programming software is used to write the ladder diagram control program for the pipe bending machine to control the temperature and speed required for bending. Keywords: Pipe bending machine; PLC; Control system; Software programming.

点击了解资源详情

点击了解资源详情

点击了解资源详情

2022-12-06 上传

2021-10-07 上传

2020-07-02 上传

2021-09-21 上传

2023-06-29 上传

zhangao_fengg

- 粉丝: 30

- 资源: 5万+

最新资源

- Raspberry Pi OpenCL驱动程序安装与QEMU仿真指南

- Apache RocketMQ Go客户端:全面支持与消息处理功能

- WStage平台:无线传感器网络阶段数据交互技术

- 基于Java SpringBoot和微信小程序的ssm智能仓储系统开发

- CorrectMe项目:自动更正与建议API的开发与应用

- IdeaBiz请求处理程序JAVA:自动化API调用与令牌管理

- 墨西哥面包店研讨会:介绍关键业绩指标(KPI)与评估标准

- 2014年Android音乐播放器源码学习分享

- CleverRecyclerView扩展库:滑动效果与特性增强

- 利用Python和SURF特征识别斑点猫图像

- Wurpr开源PHP MySQL包装器:安全易用且高效

- Scratch少儿编程:Kanon妹系闹钟音效素材包

- 食品分享社交应用的开发教程与功能介绍

- Cookies by lfj.io: 浏览数据智能管理与同步工具

- 掌握SSH框架与SpringMVC Hibernate集成教程

- C语言实现FFT算法及互相关性能优化指南