没有合适的资源?快使用搜索试试~ 我知道了~

首页台达DVP04AD - S 模拟量输入模块.pdf

台达DVP04AD - S 模拟量输入模块.pdf

需积分: 39 16 下载量 144 浏览量

更新于2023-03-16

评论

收藏 1.21MB PDF 举报

台达DVP04AD - S 模拟量输入模块pdf,台达DVP系列产品。DVP04AD-S类比信号输入模组可接受外部4点类比信号输入(电压或电流皆可),将之转换成14位元之数位信号。透过DVP-PLC SS/SA/SX/SC/SV主机程式以指令FROM/TO来读写模组內之资料,模组內具有49个CR (Control Register) 暂存器,每個暂存器有16 bits。DVP04AD-S类比信号输入模组可经由RS-485通讯来更新韧体版本。电源单元与模组分离,体积小,安装容易。使用者可经由配线选择电压输入或电流输入。电源输入范围 ±10VDC (解析度为1.25mV)。电流输入范围±20mA (解析度为5μA)。

资源详情

资源评论

资源推荐

DVP-1960130-01

Warning

Please carefully read this instruction sheet before use.

The DC input power must be OFF before any maintenance.

This is an OPEN-TYPE built-in DVP04AD-S, and the DVP04AD-S is certified to meet the safety requirements of

IEC 61131-2 (UL 508) when installed in the enclosure to prevent high temperature, high humidity, exceessive

vibration, corrosive gases, liquids, airbome dust or metallic particles. Also, it is equipped with protective methods

such as some special tool or key to open the enclosure, so as to avoid the hazard to users or any damage to the

DVP04AD-S.

DO NOT connect the AC power to any of the input/output terminals, or it may damage to the DVP04AD-S. Make

sure that all the wiring is well conducted prior to power on.

DO NOT touch the internal circuit for at least 1 minute after the power supply is OFF.

Make sure that the DVP04AD-S is properly grounded , to prevent any electromagnetic noise.

Introduction

Model Explanation & Peripherals

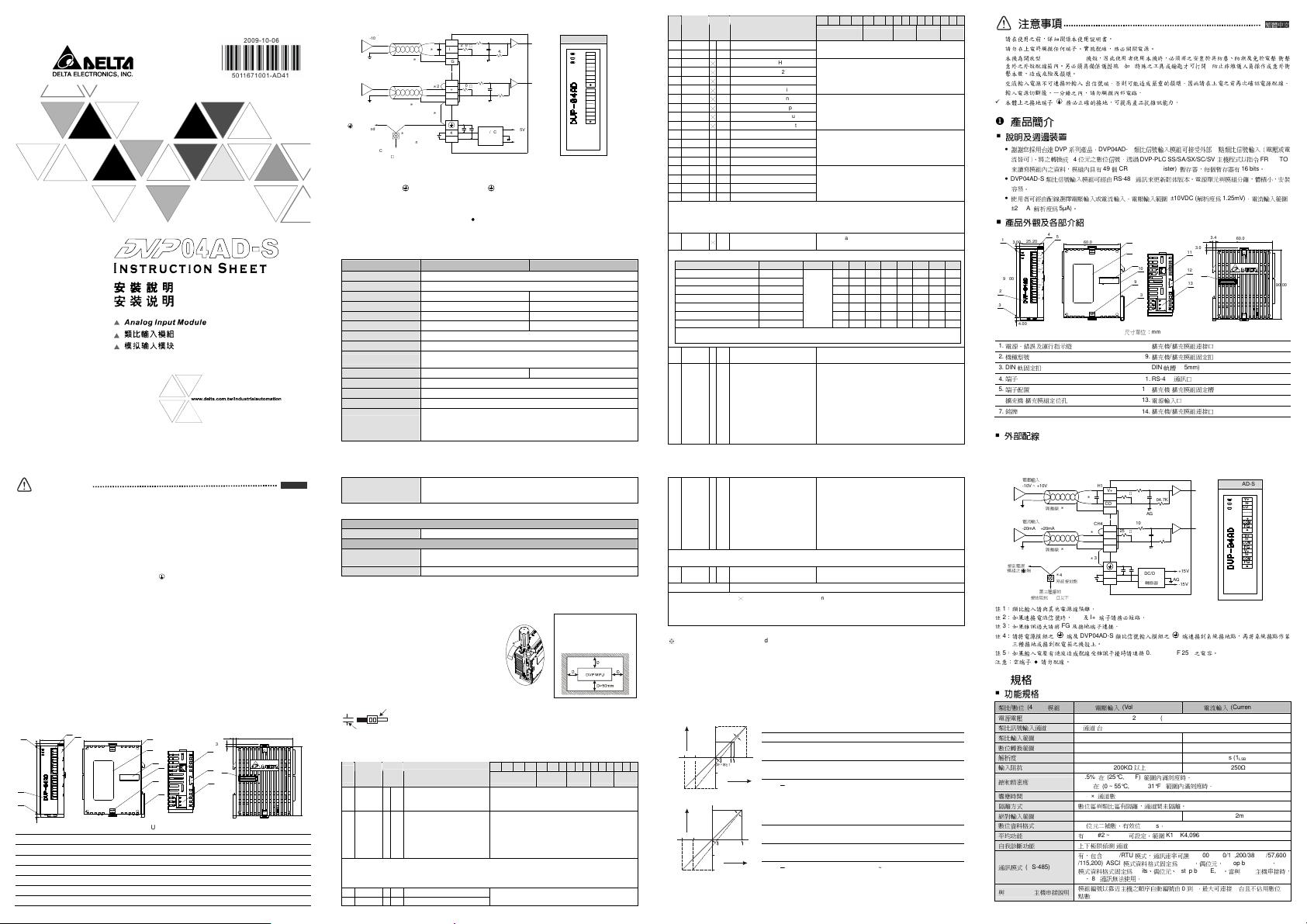

Thank you for choosing DELTA PLC DVP Series. The analog input module receives external 4-point

analog signal input (voltage or current) and converts it into 14 bits digital signal. The analog input module

of DVP04AD-S series can read/write the data of analog input module by using instructions FROM/TO via

DVP-PLC SS/SA/SX/SC/SV Series MPU program. There are 49 CR (Control Register, each register has

16-bit) in each module.

The software version of DVP04AD-S analog input module can be updated via RS-485 communication.

Power unit and module are separate. Size is small and easy to install.

Users can select input from voltage or current via wiring. Voltage input range is ±10VDC (resolution is

1.25mV). Current input range is ±20mA (resolution is 5µA).

Product Profile & Outline

90.00

4.00

3.00

25.20

1

2

3

4

60.0

0

5

6

7

8

9

3

10

●

FG

V+

I+

COM

C

H

1

FG

V+

I+

COM

C

H

2

FG

V+

I+

COM

C

H

3

FG

V+

I+

COM

C

H

4

11

12

13

3.4

90.00

60.0

0

3.00

14

●

Unit: mm

1. Status indicator (POWER, RUN and ERROR) 8. Expansion port

2. Model name 9. Expansion unit clip

3. DIN rail clip 10. DIN rail (35mm)

4. I/O terminals 11. RS-485 communication port

5. I/O point indicator 12. Mounting rail of the expansion unit

6. Mounting hole of the expansion unit 13. DC power input

7. Nameplate 14. Expansion port

ENGLISH

External Wiring

Voltage

Input

-10V ~ +10V

Current Input

-20mA ~ +20mA

V+

COM

Isolation Wire

1

*

*

5

FG

I+

250

Ω

~

~

V+

FG

I+

*

2

CH1

CH4

250

Ω

24+

24-

*

3

AG

+15V

-15V

DC/DC

Converter

*

4

System

Grounding

Class 3 Grounding

(100 or less)

Ω

COM

CH1

CH4

104.7K

104.7K

AG

104.7K

104.7K

AG

Isolation Wire

1

*

terminal of

power module

DVP04AD-S

V+

I+

COM

FG

V+

I+

COM

FG

I+

COM

FG

V+

I+

COM

FG

V+

Note 1: Please isolate analog input and other power wiring.

Note 2: If current signal is connected, please short out V+ and I+ terminals.

Note 3: If noise is significant, please connect FG to grounding.

Note 4: Please connect terminal of power module and terminal of analog input module to system earth point

and make system earth point be grounding or connects to machine cover.

Note 5: If noise interferes from loaded input wiring terminal is significant, please connect a capacitor with 0.1 ~ 0.47µF

25V for noise filtering.

Warning: DO NOT wire to the No function terminal .

Specifications

Functions

Analog/Digital (4A/D) module

Voltage input Current input

Power supply voltage 24VDC (20.4VDC ~ 28.8VDC) (-15% ~ +20%)

Analog input channel 4 channel/each module

Analog input range ±10V ±20mA

Digital conversion range ±8,000 ±4,000

Resolution 14 bits (1

LSB

=1.25mV) 13 bits (1

LSB

=5µA)

Input impedance > 200KΩ 250Ω

Overall accuracy ±0.5% of full scale of 25°C (77°F). ±1% of full scale during 0 ~ 55°C (32 ~ 131°F)

Response time 3ms × channels

Isolation method

It has isolation between digital area and analog area. There is no isolation among

channels.

Absolute input range ±15V ±32mA

Digital data format 2’s complementary of 16-bit, 13 significant bits

Average function Yes (CR#2 ~ CR#5 can be set and setting range is K1 ~ K4,096)

Self diagnose function Upper and lower bound detection/channels

Communication mode

(RS-485)

Modbus ASCII/RTU Mode. Communication baud rate of 4,800/9,600/19,200/

38,400/57,600/115,200. For ASCII mode, date format is 7 bits, even, 1 stop bit (7,

E, 1), while RTU mode, date format is 8 bits, even, 1 stop bit (8, E, 1). The RS-485

is disabled when the DVP04AD-S is connected in series with MPU.

Connect to DVP-PLC MPU

in series

If DVP04AD-S modules are connected to MPU, the modules are numbered from

0 – 7. 0 is the closest and 7 is the furthest to the MPU. 8 modules is the max and

they do not occupy any digital I/O points of the MPU.

Others

Power specification

Max. rated consuming power 24VDC (20.4VDC ~ 28.8VDC) (-15% ~ +20%), 2W, supply from external power.

Environment condition

Operation/storage

1. Operation: 0°C ~ 55°C (temperature), 50 ~ 95% (humidity), pollution degree 2

2. Storage: -25°C ~ 70°C (temperature), 5 ~ 95% (humidity)

Vibration/shock immunity Standard: IEC61131-2, IEC68-2-6 (TEST Fc)/IEC61131-2 & IEC68-2-27 (TEST Ea)

Installation and Wiring

Mounting Arrangements and Wiring Notes

DIN Rail Installation

The DVP-PLC can be secured to a cabinet by using the

DIN rail that is 35mm high with a depth of 7.5mm. When

mounting the PLC on the DIN rail, be sure to use the end

bracket to stop any side-to-side motion of the PLC, thus

to reduce the chance of the wires being pulled loose. On

the bottom of the PLC is a small retaining clip. To secure

the PLC to the DIN rail, place it onto the rail and gently

push up on the clip. To remove it, pull down on the

retaining clip and gently pull the PLC away from the DIN

rail. Please see the figure on the right:

For heat dissipation. Make

sure to provide a minimum

clearance of 50mm between

the unit and all sides of the

cabinet. (shown as below)

CR (Control Register)

b15

b14

b13

b12

b11

b10

b9

b8

b7

b6

b5

b4

b3

b2

b1

b0

CR

#

RS-485

parameter

address

Latched

Register name

Reserved CH4 CH3 CH2 CH1

#0

H’4000

○

R

Model type

System used, data length is 8 bits (b7 ~ b0). DVP04AD-S

model code= H’88. User can read the data from program to

check if there is expansion module.

#1

H’4001

○

R/W

Input mode setting

Input mode setting: factory setting is H’0000.

Mode 0: input voltage mode (-10V ~ +10V).

Mode 1: input voltage mode (-

6V ~ +10V).

Mode 2: input current mode (-12mA ~ +20mA).

Mode 3: input current mode (-

20mA ~ +20mA).

Mode 4: none use.

CR#1: CR#1 is used to set 4 internal channels working mode of analog input module. Every channel has four modes to

set that can be set individually. For example: if set CH1 to mode 0 (b2 ~ b0 = 000), CH2 to mode 1 (b5 ~ b3 = 001), CH3:

mode 2 (b8 ~ b6 = 010), CH4: mode 3 (b11 ~ b9 = 011). Then CR#1 is set to H’0688 and the upper bit (b12 ~ b15) will

reserved. The factory setting of CR#1 is H’0000.

#2

H’4002

○

R/W

CH1 average times

#3

H’4003

○

R/W

CH2 average times

Average times setting of channel CH1 ~ CH2.

Setting range is K1 ~ K4,096 and factory setting is K10.

Wiring

22 -16 AWG

< 1.5mm

1. Use 22-16AWG (1.5mm) single or multiple core wire on I/O wiring terminals. The

specification of the terminal is shown in the figure on the left hand side. The PLC

terminal screws shall be tightened to 1.95kg-cm (1.7 in-lbs).

2. DO NOT place the I/O signal wires and power supply wire in the same wiring duct.

3. Use 60/75°C copper wires only.

b15

b14

b13

b12

b11

b10

b9

b8

b7

b6

b5

b4

b3

b2

b1

b0

CR

#

RS-485

parameter

address

Latched

Register name

Reserved CH4 CH3 CH2 CH1

#4

H’4004

○

R/W

CH3 average times

#5

H’4005

○

R/W

CH4 average times

Average times setting of channel CH3 ~ CH4.

Setting range is K1 ~ K4,096 and factory setting is K10.

#6

H’4006

╳

R

Average value

of CH1 input signal

#7

H’4007

╳

R

Average value of CH2 input signal

#8

H’4008

╳

R

Average value of CH3 input signal

#9

H’4009

╳

R

Average value of CH4 input signal

Display average value of CH1 ~ CH4 input signal.

For example, if CR#2 (the average times of CH1) is 10, the

average of CH1 input signal is calculated every 10 times.

#12

H’400C

╳

R

present value of CH1 input signal

#13

H’400D

╳

R

present value of CH2 input signal

#14

H’400E

╳

R

present value of CH3 input signal

#15

H’400F

╳

R

present value of CH4 input signal

Display present value of CH1 ~ CH4 input signal.

#18

H’4012

○

R/W

To adjust OFFSET value of CH1

#19

H’4013

○

R/W

To adjust OFFSET value of CH2

#20

H’4014

○

R/W

To adjust OFFSET value of CH3

#21

H’ 4015

○

R/W

To adjust OFFSET value of CH4

Offset setting of CH1 ~ CH4.

Factory setting is K0 and unit is LSB.

Voltage input: setting range is K-

4,000 ~ K4,000.

Current input: setting range is K-4,000 ~ K4,000.

#24

H’4018

○

R/W

To adjust GAIN value of CH1

#25

H’4019

○

R/W

To adjust GAIN value of CH2

#26

H’401A

○

R/W

To adjust GAIN value of CH3

#27

H’401B

○

R/W

To adjust GAIN value of CH4

GAIN setting of CH1 ~ CH4. Factory setting is K4,000 and

unit is LSB.

Voltage input: setting range is K-3,200 ~ K16,000.

Current input: setting range is K-3,200 ~ K10,400.

CR#18~CR#27: Please be noticed that GAIN value – OFFSET value=+800

LSB

~ +12,000

LSB

(voltage) or +800

LSB

~

+6,400

LSB

(current). If the value difference comes up small (within range), the output signal resolution is then slim and the

variation is definitely larger. On the contrast, if the value difference exceeds the range, the output signal resolution

becomes larger and the variation is definitely smaller.

#30

H’401E

╳

R

Error status

It is the data register to save all error status.

Please refer to error code chart for detail.

CR#30: Error status value (see the table below)

Error description Content b15 ~ b8

b7

b6

b5

b4

b3

b2

b1

b0

Power source abnormal K1 (H’1) 0 0 0 0 0 0 0 1

Setting mode error K4 (H’4) 0 0 0 0 0 1 0 0

Offset/gain error K8 (H’8) 0 0 0 0 1 0 0 0

Hardware malfunction K16 (H’10) 0 0 0 1 0 0 0 0

Digital range error K32 (H’20) 0 0 1 0 0 0 0 0

Average times setting error K64 (H’40) 0 1 0 0 0 0 0 0

Instruction error K128 (H’80)

Reserved

1 0 0 0 0 0 0 0

Note: Each error code will have corresponding bit (b0 ~ b7). Two or more errors may happen at the same time. 0 means

normal and 1 means having error.

#31

H’401F

○

R/W

Communication address setting

Setting RS-485 communication address.

Setting range is 01 ~ 254 and factory setting is K1.

#32

H’4020

○

R/W

Communication baud rate setting

It is used to set communication baud rate (4,800, 9,600,

19,200, 38,400, 57,600, 115,200 bps). Communication

format: ASCII mode is 7 bits, even bit, 1 stop bit (7, E, 1),

while RTU mode is 8 bits, even bit, 1 stop bit (8, E, 1).

b0: 4,800 bps (bit/sec). b1: 9,600 bps (factory setting).

b2: 19,200 bps (bit/sec). b3: 38,

400 bps (bit/sec).

b4: 57,600 bps (bit/sec). b5: 115,200 bps (bit/sec).

b6 ~ b13: reserved.

b14: exchange low and high byte of CRC check code (only

for RTU mode). b15: ASCII/RTU mode selection.

#33

H’4021

○

R/W

Reset to factory setting and set

characteristics adjustable priority

Factory setting is H’0000.

Give CH1 setting for example:

1. When b0=0, user can set OFFSET and GAIN value of

CH1 (CR#18, CR#24). When b0=1, inhibit user to adjust

OFFSET and GAIN value of CH1 (CR#18, CR#24).

2. b1 means if characteristic register is latched. b1=0

(factory setting, latched), b1=1 (not latched).

3. When b2 is set to 1, all settings will be reset to factory

setting.

CR#33 is used to set the internal function priority. For example: characteristic register. Output latched function will save

output setting in the internal memory before power loss.

#34

H’4022

○

R

Firmware version

In hexadecimal to display software version.

For example: H’010A means 1.0A.

#35 ~ #48

System used

Symbols:

○

means latched.

╳

means not latched. R means can read data by using FROM instruction or RS-485.

W means can write data by using TO instruction or RS-485.

LSB (Least Significant Bit): 1. Voltage input: 1

LSB

=10V/8,000=2.5mV.

2. Current input: 1

LSB

=20mA/4,000=5µA.

Explanation:

※

The corresponding parameters address H

’

4000 ~ H

’

4022 of CR#0 ~ CR#34 are provided for user to read/

write data via RS-485.

A. Communication baud rate: 4,800, 9,600, 19,200, 38,400, 57,600, 115,200 bps.

B. Communication format: ASCII mode is 7 bits, even bit, 1 stop bit (7, E, 1), while RTU mode is 8 bits,

even bit, 1 stop bit (8, E, 1).

C. Function code: 03’H - read data from register. 06’H - write one word into register. 10’H - write multiple

words into register.

Adjust A/D Conversion Characteristic Curve

Voltage input mode:

Mode 0 of CR#1:

GAIN=5V (4,000

LSB

), OFFSET=0V (0

LSB

).

Mode 1 of CR#1:

GAIN=6V (4,800

LSB

), OFFSET=2V (1,600

LSB

).

GAIN:

Voltage input value when digital output is 4,000.

Setting range is -3,200

LSB

~ +16,000

LSB

.

OFFSET:

Voltage input value when digital output is 0.

Setting range: -4,000

LSB

~ +4,000

LSB

.

+8,000

+4,000

-4,000

10V

-8, 000

-6V-10 V

6V

5V

2V

0

GAIN

Dig ital

output

Mode 0

Mode 1

Voltage input

GAIN

-

OFFSET:

Setting range is +800

LSB

~ +12,000

LSB

.

Current input mode:

Mode 2 of CR#1:

GAIN=20mA (4,000

LSB

), OFFSET=4mA (800

LSB

).

Mode 3 of CR#1:

GAIN=20mA (4,000

LSB

), OFFSET=0mA (0

LSB

).

GAIN:

Current input value when digital output is +4,000.

Setting range is -3,200

LSB

~ +10,400

LSB

.

OFFSET:

Current input value when digital output value is 0.

Setting range is -4,000

LSB

~ +4,000

LSB

.

+4,000

-4,000

-12mA-20mA

4mA

0

OFFSET

20mA

GAIN

Digit al

output

Mode 3

Mode 2

Current input

GAIN

-

OFFSET:

Setting range is +800

LSB

~ +6,400

LSB

.

The chart above is to adjust

A/D conversion characteristic curve of voltage input mode and current input mode.

Users can adjust conversion characteristic curve by changing OFFSET values (CR#18 ~ CR#21) and GAIN

values (CR#24 ~ CR#27) depend on application.

注意事項

請在使用之前,詳細閱讀本使用說明書。

請勿在上電時觸摸任何端子。實施配線,務必關閉電源。

本機為開放型

(OPEN TYPE)

機殼,因此使用者使用本機時,必須將之安裝於具防塵、防潮及免於電擊

/

衝擊

意外之外殼配線箱內。另必須具備保護措施

(

如

:

特殊之工具或鑰匙才可打開

)

防止非維護人員操作或意外衝

擊本體,造成危險及損壞。

交流輸入電源不可連接於輸入

/

出信號端,否則可能造成嚴重的損壞,因此請在上電之前再次確認電源配線。

輸入電源切斷後,一分鐘之內,請勿觸摸內部電路。

本體上之接地端子

務必正確的接地,可提高產品抗雜訊能力。

產品簡介

說明及週邊裝置

謝謝您採用台達

DVP

系列產品。

DVP04AD-S

類比信號輸入模組可接受外部

4

點類比信號輸入(電壓或電

流皆可),將之轉換成

14

位元之數位信號。透過

DVP-PLC SS/SA/SX/SC/SV

主機程式以指令

FROM/TO

來讀寫模組內之資料,模組內具有

49

個

CR (Control Register)

暫存器,每個暫存器有

16 bits

。

DVP04AD-S

類比信號輸入模組可經由

RS-485

通訊來更新韌体版本。電源單元與模組分離,體積小,安裝

容易。

使用者可經由配線選擇電壓輸入或電流輸入。電壓輸入範圍

±10VDC (

解析度為

1.25mV)

。電流輸入範圍

±20mA (

解析度為

5µA)

。

產品外觀及各部介紹

90.00

4.00

3.00

25.20

1

2

3

4

60.0

0

5

6

7

8

9

3

10

●

FG

V+

I+

COM

C

H

1

FG

V+

I+

COM

C

H

2

FG

V+

I+

COM

C

H

3

FG

V+

I+

COM

C

H

4

11

12

13

3.4

90.00

60.0

0

3.00

14

●

尺寸單位:

mm

1.

電源、錯誤及運行指示燈

8.

擴充機

/

擴充模組連接口

2.

機種型號

9.

擴充機

/

擴充模組固定扣

3.

DIN

軌固定扣

10.

DIN

軌糟

(35mm)

4.

端子

11.

RS-485

通訊口

5.

端子配置

12.

擴充機

/

擴充模組固定槽

6.

擴充機

/

擴充模組定位孔

13.

電源輸入口

7.

銘牌

14.

擴充機

/

擴充模組連接口

外部配線

繁體中文

接至電源

模組之

端

電壓輸入

-10V ~ +10V

電流輸入

-20mA ~ +20mA

V+

COM

隔離線

1

*

*

5

FG

I+

250

Ω

~

~

V+

FG

I+

*

2

CH1

CH4

250

Ω

24+

24-

*

3

AG

+15V

-15V

DC/DC

轉換器

*

4

系統接地點

第三種接地

(

接地阻抗

100

以下

)

Ω

COM

CH1

CH4

104.7K

104.7K

AG

104.7K

104.7K

AG

隔離線

1

*

DVP04AD-S

V+

I+

COM

FG

V+

I+

COM

FG

I+

COM

FG

V+

I+

COM

FG

V+

註

1

:類比輸入請與其他電源線隔離。

註

2

:如果連接電流信號時,

V+

及

I+

端子請務必短路。

註

3

:如果雜訊過大請將

FG

及接地端子連接。

註

4

:請將電源模組之

端及

DVP04AD-S

類比信號輸入模組之

端連接到系統接地點,再將系統接點作第

三種接地或接到配電箱之機殼上。

註

5

:如果輸入電壓有漣波造成配線受雜訊干擾時請連接

0.1 ~ 0.47µF 25V

之電容。

注意:空端子

請勿配線。

規格

功能規格

類比

/

數位

(4A/D)

模組

電壓輸入

(Voltage input)

電流輸入

(Current input)

電源電壓

24VDC (20.4VDC ~ 28.8VDC) (-15% ~ +20%)

類比訊號輸入通道

4

通道

/

台

類比輸入範圍

±10V ±20mA

數位轉換範圍

±8,000 ±4,000

解析度

14 bits (1

LSB

=1.25mV) 13 bits (1

LSB

=5µA)

輸入阻抗

200KΩ

以上

250Ω

總和精密度

±0.5%

在

(25°C, 77°F)

範圍內滿刻度時。

±1%

在

(0 ~ 55°C, 32 ~ 131°F)

範圍內滿刻度時。

響應時間

3ms ×

通道數

隔離方式

數位區與類比區有隔離,通道間未隔離。

絕對輸入範圍

±15V ±32mA

數位資料格式

16

位元二補數,有效位

11 bits

。

平均功能

有

(CR#2 ~ CR#5

可設定,範圍

K1 ~ K4,096)

自我診斷功能

上下極限偵測

/

通道

通訊模式

(RS-485)

有,包含

ASCII/RTU

模式,通訊速率可選

(4,800/9,600/19,200/38,400/57,600

/115,200), ASCII

模式資料格式固定為

7 bits

、偶位元、

1 stop bit (7, E, 1)

,

RTU

模式資料格式固定為

8 bits

、偶位元、

1 stop bit (8, E, 1)

。當與

PLC

主機串接時,

RS-485

通訊無法使用。

與

DVP-PLC

主機串接說明

模組編號以靠近主機之順序自動編號由

0

到

7

,最大可連接

8

台且不佔用數位

I/O

點數

weixin_38744435

- 粉丝: 370

- 资源: 2万+

上传资源 快速赚钱

我的内容管理

收起

我的内容管理

收起

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

会员权益专享

最新资源

- 2023年中国辣条食品行业创新及消费需求洞察报告.pptx

- 2023年半导体行业20强品牌.pptx

- 2023年全球电力行业评论.pptx

- 2023年全球网络安全现状-劳动力资源和网络运营的全球发展新态势.pptx

- 毕业设计-基于单片机的液体密度检测系统设计.doc

- 家用清扫机器人设计.doc

- 基于VB+数据库SQL的教师信息管理系统设计与实现 计算机专业设计范文模板参考资料.pdf

- 官塘驿林场林防火(资源监管)“空天地人”四位一体监测系统方案.doc

- 基于专利语义表征的技术预见方法及其应用.docx

- 浅谈电子商务的现状及发展趋势学习总结.doc

- 基于单片机的智能仓库温湿度控制系统 (2).pdf

- 基于SSM框架知识产权管理系统 (2).pdf

- 9年终工作总结新年计划PPT模板.pptx

- Hytera海能达CH04L01 说明书.pdf

- 数据中心运维操作标准及流程.pdf

- 报告模板 -成本分析与报告培训之三.pptx

资源上传下载、课程学习等过程中有任何疑问或建议,欢迎提出宝贵意见哦~我们会及时处理!

点击此处反馈

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功

评论0