没有合适的资源?快使用搜索试试~ 我知道了~

首页一维弹塑性本构编程入门

1

Nonlinear Static - 1D Plasticity - Various Forms of Isotropic Hardening

by Louie L. Yaw

Walla Walla University

Draft Date January 25, 2012

key words: plasticity, algorithms, nonlinear analysis, isotropic hardening, algorithmic tan-

gent modulus, elasto-plastic tangent modulus, Kuhn-Tucker conditions, consistency param-

eter, internal hardening variable, equivalent plastic strain, flow rule, consistency condition,

yield condition

1 Introduction

Metals loaded beyond the elastic limit deform plastically. It is often the goal in structural

mechanics to model plastic deformations of such metals in a computational setting. Creating

algorithms to model the combined effect of elastic and plastic deformations is not trivial.

However, plasticity for the one dimensional case is a good introduction to the concepts

necessary to construct such algorithms. Hence, this article presents plasticity from a one

dimensional point of view and derives algorithms for a variety of different ha r d en i n g models.

It is the g oal of this article to introduce students to algorithmic plasticity (nonlinear material)

models and also pave the way for future learning in the area of three dimensional plasticity.

One dimensional plasticity is hel p fu l as an introduction and as an intermediate step to-

ward more difficult topics, but it is also practical for bar elem ents often modeled in structural

analysis software. It is therefore worth noting that the information learn ed herein i s useful

for the implementation of plasticity by modifying a standar d linear truss analysis program.

Only small strains are considered.

2 Elastic and plastic behavior

Material testing is often accomplished by tensile tests. Plots of stress versus strain are often

created from tension tests. For many materials the plot of stress versus strain is linear for

stresses below a certain threshold called the yield stress. If the material is loaded beyond this

point the material yields and begins to deform plastically. How the material deforms after

passing t h e yield point varies from material to material. For instance many materials exhibit

hardening after reaching the yield limit. This hardening is exhibited by increasing resistance

to load after yielding, but th i s increase in resistance is much less than the resistance provided

by the material before yi el d i n g .

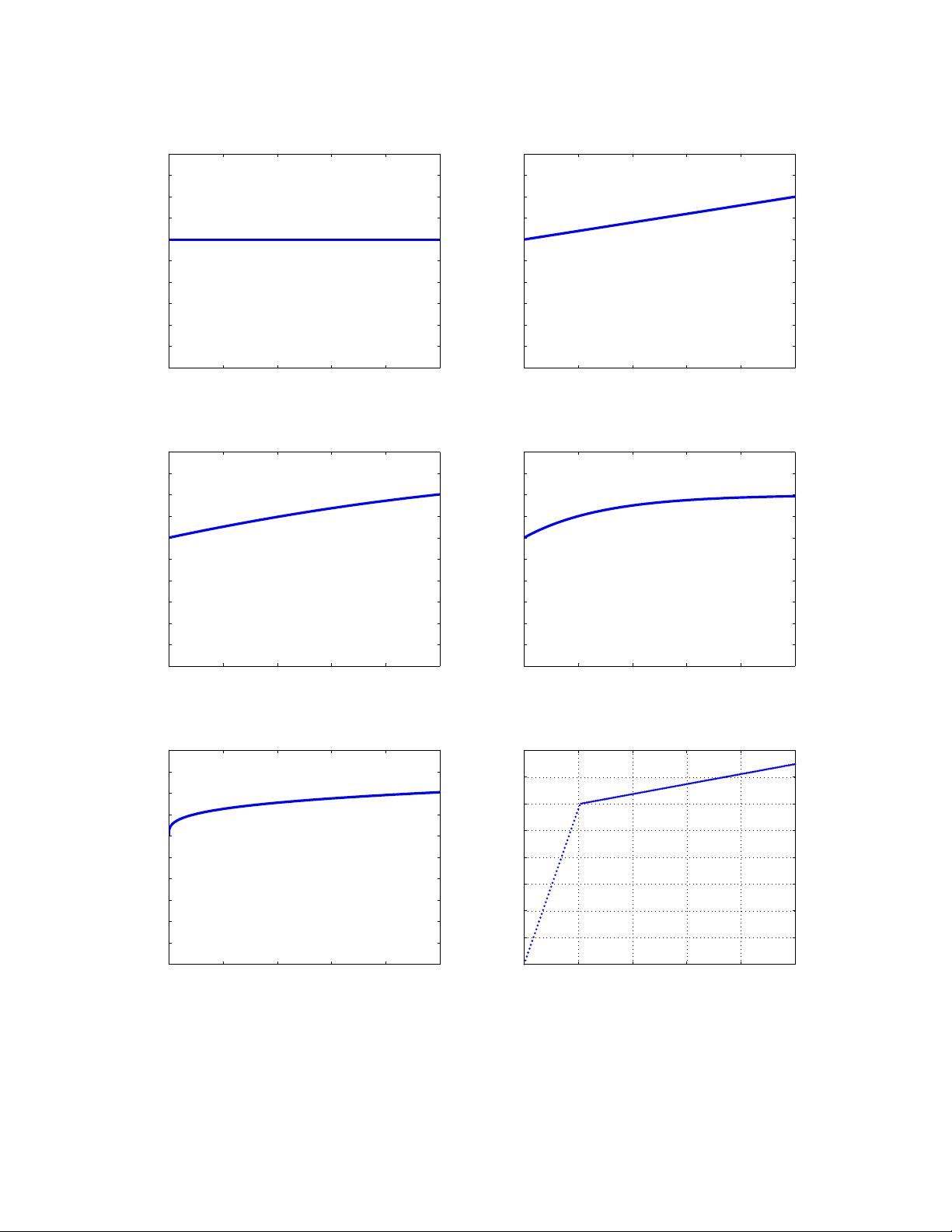

If hardening is present the post yield behavior exhibits both increasing elastic strain and

increasing plastic strain. A variety of models are availab l e to try and s imulate how the

plastic strain increases with increasing stress. The post yield behavior is often modeled

by specifying how the yield stress evolves with increasing plastic strain. A variety of such

models are shown in Figure 1. In the plots the yield point is shown, σ

y

= 30 ksi, a n d the

hardening behavior is plotted based on the formulas sh own. It is important to note that the

plots are of stress versus plastic strain. When plots of stress versus total strain a re created

2

0 1 2 3 4 5

x 10

−3

0

5

10

15

20

25

30

35

40

45

50

No Hardening − Perfect Plasticity

Plastic Strain, ε

p

Stress, σ

G(ε

p

)=σ

y

(a)

0 1 2 3 4 5

x 10

−3

0

5

10

15

20

25

30

35

40

45

50

Linear Hardening

Plastic Strain, ε

p

Stress, σ

G(ε

p

)=σ

y

+Kε

p

(b)

0 1 2 3 4 5

x 10

−3

0

5

10

15

20

25

30

35

40

45

50

Quadratic Hardening Formula

Plastic Strain, ε

p

Stress, σ

G(ε

p

)=σ

y

+E(ε

p

−Qε

p

2

)

(c)

0 1 2 3 4 5

x 10

−3

0

5

10

15

20

25

30

35

40

45

50

Voce Hardening Formula

Plastic Strain, ε

p

Stress, σ

G(ε

p

)=σ

y

+(σ

u

−σ

y

)(1−e

−δ ε

p)

(d)

0 1 2 3 4 5

x 10

−3

0

5

10

15

20

25

30

35

40

45

50

Ramberg Osgood Formula

Plastic Strain, ε

p

Stress, σ

G(ε

p

)=σ

y

+Cε

p

m

(e)

0 1 2 3 4 5

x 10

−3

0

5

10

15

20

25

30

35

40

Total Strain, ε

Stress σ(ksi)

Stress versus Strain − Linear Hardening

(f)

Figure 1: Plastic Strain Hardening Models (σ

y

= 30 ksi): (a) No Hardening - Perfect

Plasticity, (b) Lin ea r Hardening, (c) Quadratic Hardening, (d) Voce Hardening, (e) Ramb er g

Osgoo d Hardenin g , (f) Stress versus total strain with linear hardening.

3

based on these models, the post yi el d behavior will look si m i la r but will be different since

the post yield behavior also accounts for increasing elastic strains. Hence, for example, in

the case of Figure 1(b) the post yield slope is called the plastic modulus. Wher eas a plot of

stress versus total strain using linear hardening, Figure 1(f), has a post yield slope that is

called the elasto-pl as ti c modulus and it is not the same as the plastic modulus. Because of

hardening the yield p oi nt has increased and as a result more elastic strain exi st s due to the

higher yi eld point. Hence, for hardening materials, in cr eas e in pl as ti c strain is accompanied

with increase in elastic strain. In later sections the derivat i on of the elasto-plastic modulus

is illustrated for the models given.

3 Definitions

Basic termino lo gy helpful for understanding the concepts involved in modeling plasticity is

presented in this section. The definitions given are not exhau st i ve, but provide at least the

basic ideas. S o m e of the terms are easy to defin e clearly. Other terms can be defined but are

better understood after working with the material in following secti on s . The notation used

closely follows that given by Simo and Hughes [6].

Brief definitions of the m ost important terminolo gy are as follows. Elastic strain, ε

e

, is

any strain that takes place before exceeding the yield stress. However, it is important t o

note that, for harden i ng materials, elastic strain is increasing during post yield also. Hence,

strain that is rem oved during unloading is a better definition of elastic strain. Plasti c strain,

ε

p

, is permanent strain that remains after unloading. Total strain is the sum of elastic strain

and plastic strain, ε = ε

e

+ ε

p

. Any time plastic strains are taking place it follows that

plastic flow is taking place. When hardening occurs the value of the yield stress changes.

For this reason, plasticity models u se internal h ar dening variables as a means for keeping

track of accumulated hardening. For isotropic har dening, hardening accumulates if p l as ti c

strain is p osi t i ve or negative, hence the internal hardening variable keeps track of the total

change in plastic strain. Therefore, the isotropic internal hardening variable α is called the

equivalent plastic strain. A yield cond i t io n (a funct i on ) is used to mathemat i cal l y id entify

when yielding happens. Often in the literature the yield condi t i on i s denoted by f. It

typically includes the current level of stress minus the init i al yield stress added to a function

of α which describes the typ e of hardening. Examples of yield conditions are p r ovided later

in this paper. As plastic st ra i n takes place, α is updated and changes, the yield condition f

is calculated and is either a negative value or a positive value. If it is negative the current

level of stress is below y ie ld and only elastic strains are increasing. If it is positive th e

current level of stress is a bove the yield stress and (with the presence of hardening) elastic

and plastic strains are increasing. However, in a ct u al i ty f > 0 is not allowed and requires

calculation o f the amount of plastic flow and how the hardening level evolves such that f = 0

is achieved. This is accomplished by solving for a consistency parameter γ, which allows a

means for determining the level of plastic flow and hardening such that t h e condition f = 0

is satisfied. The variable γ is called th e consistency parameter because it is deteremined so

that all relevant variables are consistent with the requirement that f = 0 when plastic flow is

taking place. This is a rather involved process and is difficult to describe in words. The whole

process of elastic loading and unloading or elasto-plastic loading and unloading requires a

4

careful mathematical description. This has led researchers to u se Kuhn - Tucker cond i t i on s.

The Kuhn- Tucker conditions are γ ≥ 0, f(σ) ≤ 0, and γf(σ) = 0. These conditions or rules

are used to construct the mathematical algor i thms which model the process of plastic flow

(for a more in depth discussion th e reader i s referred to Simo and Hughes [6]). A consi st ency

condition is also used and is written as γ

˙

f = 0, if f = 0. The sign function i s often used in

the mathematics of plasticity algorith m s . The function takes any var ia b l e and returns − 1 if

the variable is negative and +1 if the variab l e is positive. Plasticity algorithms are often used

in finite element analysis programs to model nonli n ear material behavior. In such cases the

finite element analysis program is incremental in nature. Each new load increment increases

stress levels, strain levels and displacements. Hence, d u r i n g each of these increments the

plasticity algori t h m is used at the elem ent l evel in the analysis program. At the beginning of

each increment (or load step) it is not known wh et h er the new level of stress cau se s yielding

(in a pa r ti cular element) or not. For this reason it is initially assume d that the incremental

stress is elastic. In the plasticity algorithms, the resulting new stress level is termed a trial

stress. This trial stress is plugged into the yield condition f and the rules of th e algorithm

are followed as necessary. In the course of the algorithm the correct new str ess level is

determined (ie, the trial stress is corrected if the stress incr em ent was not entirely elastic).

In some derivations given in this paper derivatives with respect to time such as

dα

dt

= ˙α are

used. However, the type of m at er i al models described in this paper are rate independent,

so it may seem odd to take derivatives with r espect to time. Hence, in this setting the

interpretation of derivatives with respect to time really mean changes with respect to a load

step or load increment in a finite el em ent analysis program. For example, if the current value

of the internal var i able α is α

n

then during the load in cr e m ent the variable may increase by an

amount ∆α such that the new va lue of α is α

n+1

= α

n

+∆α. In this example ∆α is analogous

to ˙α. Ano t h er way to look at this is to say that (in a rate independent material model) a load

increment is like a time increm e nt. This is the reason derivatives with respect to time are used

in the literature even in rate independent material models. In some theoretical derivations

γ i s us ed to den ot e the consi st en cy p ar am et er . However, in the plasticity model algorithms

∆γ is used to denote the consistency paramenter. Otherwise, there is no difference between

γ and ∆γ used in th i s paper. For t he 1D plasticity case th e algorithmic tangent m odulus

is equivalent to the elasto-plastic modulus. In higher dimensions this is not true. For some

plasticity models the yield function is complicated enough that algebr ai cal l y solving for the

consistency par am et er is not possible and hence it must be solved for using Newton-Raphson

iterations. In this process, in order to preserve the second order rate of convergence of the

Newton-Raphson method (which is likely also taking place at the global level of the nonlinear

finite element program) it is necessary to have a consistent variation (or d er i vative) of stress

with respect to the total s t ra i n . To get such a consistent variation it is necessary to t a ke the

derivative of th e algorithmic stress wit h respect to the total strain varia b l e. The al gor i t h m i c

tangent modulus is specifically derived by taki n g the derivative

∂σ

(k)

n+1

∂ε

(k)

n+1

= C

(k)

n+1

. This is a

derivative of the algorithmic stress and hence results in th e a l gor i t h m i c tangent modulus,

C

(k)

n+1

. How plastic strain evolves in pl as t ici ty algorithms is called a flow rule. In this paper

the flow r u l e takes the form ˙ε

p

= γ

df

dσ

= γsign(σ). The isotropic hardening law takes the

form ˙α = ∆α = γ.

5

4 1D P la s ti ci ty General Isotropic Hardening

The al go r it hmic pieces of one dimensional plasticity with a general expression for isotropic

hardening is presented next. The derivations and notation closely follows that given by [6].

4.1 Derivatio n of Elasto-Plastic Tangent Modulus

As usual the modulus of elasticity is E, the equivalent plastic strain is α and the total strai n

is defined as

ε = ε

p

+ ε

e

. (4.1)

Stress is linear elastic when f < 0 and is calculated as

σ = Eε

e

= E(ε − ε

p

) (4.2)

Kinematic hardening is neglected and the flow rule is assumed as

˙ε

p

= γsign(σ). (4.3)

The yield condition is defined as follows:

f(σ) = |σ| − G(α) (4.4)

,where G(α) is a yield stress function which includes the type of isotr o p i c hardeni n g , which

is possibly a function of α. The customary Kuhn-Tucker conditions apply (γ ≥ 0, f(σ) ≤ 0,

and γf(σ) = 0). If f(σ) is to be zero the consistency conditio n requires that γ

˙

f(σ) = 0.

Hence, when γ > 0,

˙

f = 0 so t hat by the chain rule

˙

f =

∂f

∂σ

∂σ

∂t

+

∂f

∂G

∂G

∂α

∂α

∂t

= 0. (4.5)

Inserting each partial derivati ve i nto the above fo r mula gives

˙

f = sign(σ) ˙σ + (−1)

∂G

∂α

˙α = 0. (4.6)

Recall that ˙α = γ, ˙σ = E( ˙ε − ˙ε

p

) and ˙ε

p

= γsign(σ). Substituting this information into

(4.6) yields

˙

f = sign(σ)E( ˙ε − γsign(σ)) −

∂G

∂α

γ = 0. (4.7)

Recognizing that (sign(σ))

2

= 1 and solving for γ gives

γ =

sign(σ)E ˙ε

E +

∂G

∂α

. (4.8)

With the above results in hand the elasto-plastic tangent modulus, C

ep

=

dσ

dε

, is found as

follows. Observe that ˙σ =

dσ

dε

˙ε. Then using (4.2), (4.3) and (4.8) yields

˙σ = E( ˙ε − ˙ε

p

) = E( ˙ε − γsign(σ)) = E( ˙ε −

(sign(σ))

2

E ˙ε

E +

∂G

∂α

). (4.9)

剩余24页未读,继续阅读

qq_15272621

- 粉丝: 4

上传资源 快速赚钱

我的内容管理

展开

我的内容管理

展开

我的资源

快来上传第一个资源

我的资源

快来上传第一个资源

我的收益 登录查看自己的收益

我的收益 登录查看自己的收益 我的积分

登录查看自己的积分

我的积分

登录查看自己的积分

我的C币

登录后查看C币余额

我的C币

登录后查看C币余额

我的收藏

我的收藏  我的下载

我的下载  下载帮助

下载帮助

最新资源

- DeepFreeze密码移除工具6.x版本使用教程

- MQ2烟雾传感器无线报警器项目解析

- Android实现消息推送技术:WebSocket的运用解析

- 利用jQuery插件自定义制作酷似Flash的广告横幅通栏

- 自定义滚动时间选择器,轻松转换为Jar包

- Python环境下pyuvs-rt模块的使用与应用

- DLL文件导出函数查看器 - 查看DLL函数名称

- Laravel框架深度解析:开发者的创造力与学习资源

- 实现滚动屏幕背景固定,提升网页高端视觉效果

- 遗传算法解决0-1背包问题

- 必备nagios插件压缩包:实现监控的关键

- Asp.Net2.0 Data Tutorial全集深度解析

- Flutter文本分割插件flutter_break_iterator入门与实践

- GD Spi Flash存储器的详细技术手册

- 深入解析MyBatis PageHelper分页插件的使用与原理

- DELPHI实现斗地主游戏设计及半成品源码分析

安全验证

文档复制为VIP权益,开通VIP直接复制

信息提交成功

信息提交成功