Overview

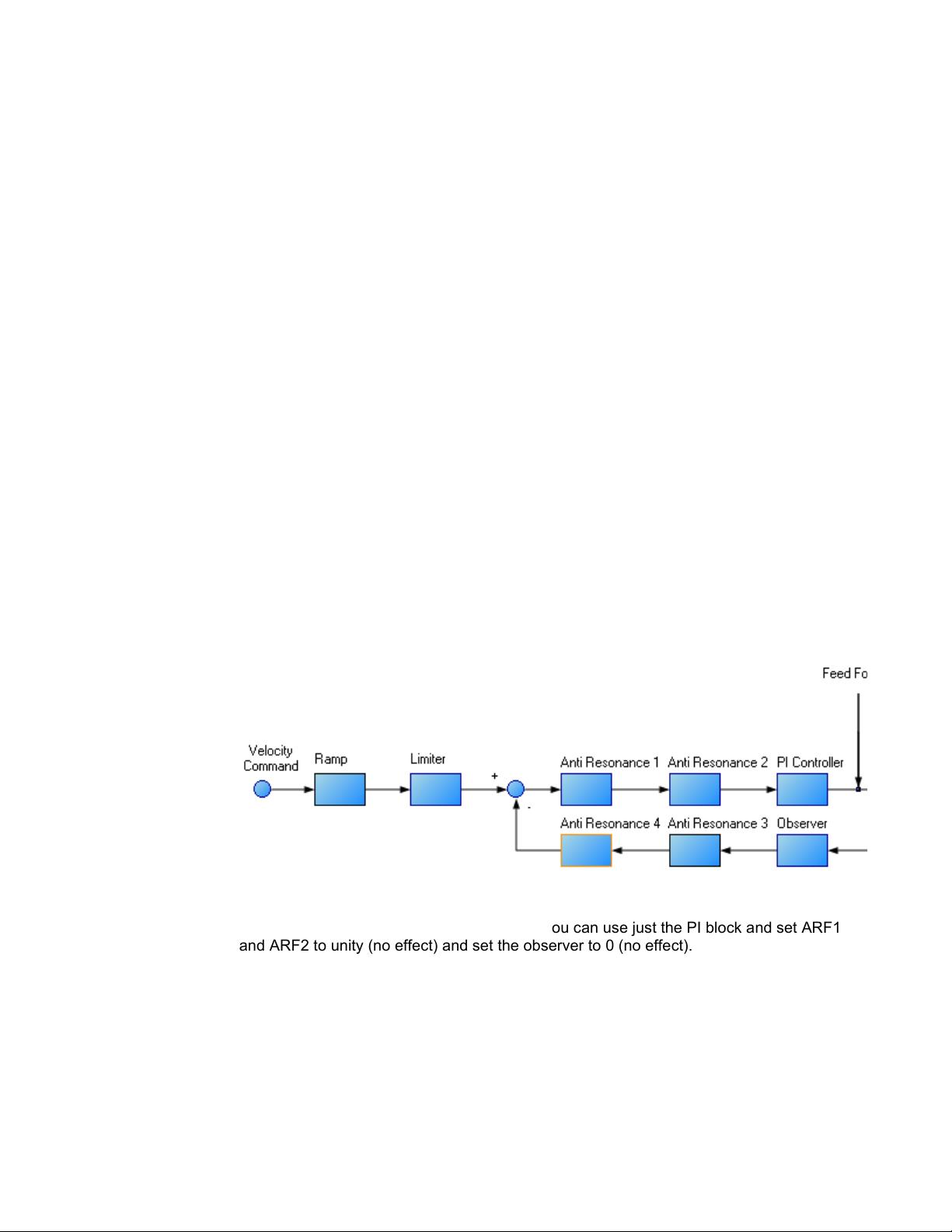

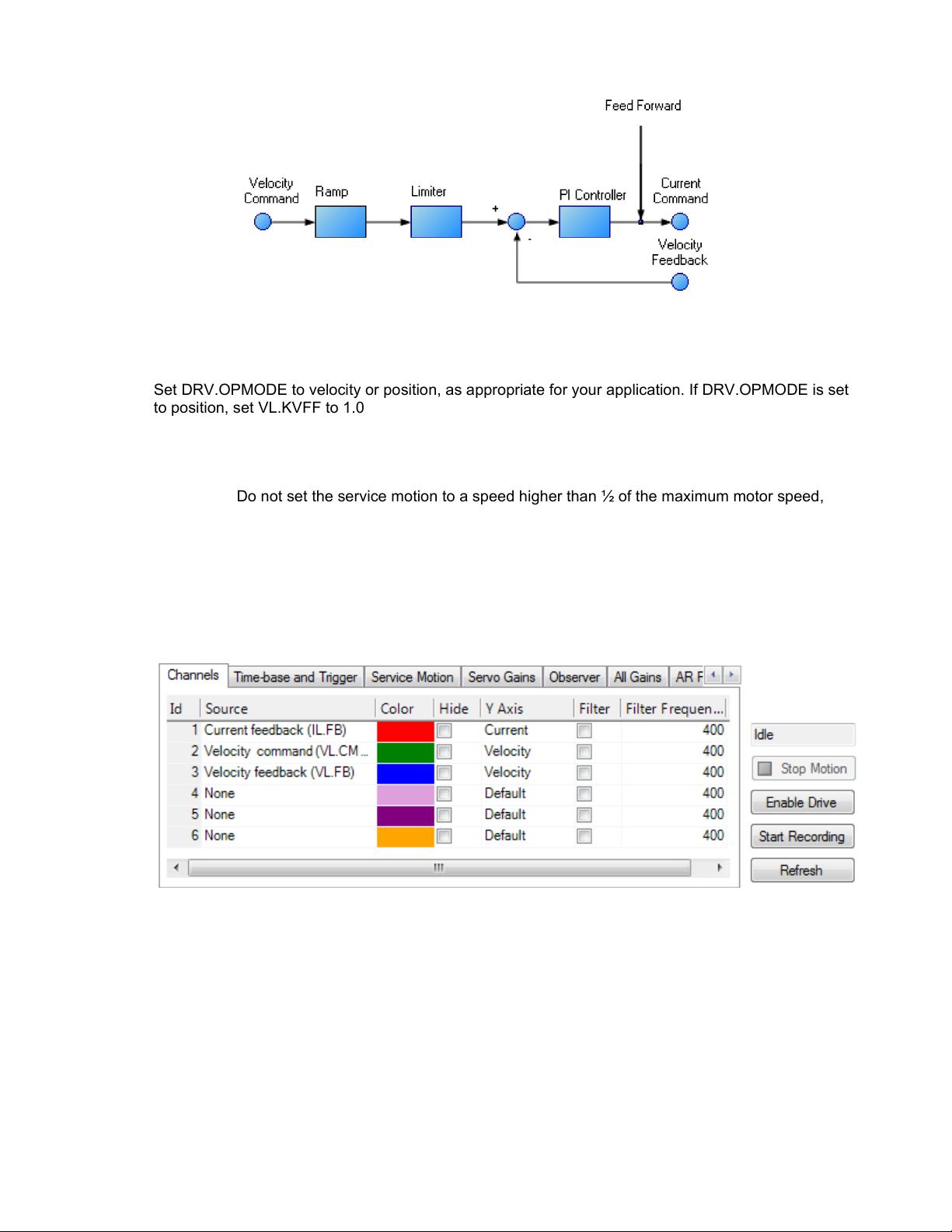

This section covers tuning the velocity and position loops in the AKD. Servo tuning is the

process of setting the various drive coefficients that are needed for the drive to optimally

control the servo motor for your application. There are different ways to tune, and several

are covered here. We will give you guidance on what the different methods of tuning are

and when to use them.

The AKD works in three major operation modes: torque, velocity, and position operation

mode. No servo loop tuning is required for torque mode. Velocity loop and position loop

tuning are covered below.

The AKD has an auto tuner that will provide the tuning that many applications will need.

This section describes the tuning process and how to tune the AKD, specifically for cases

where the user does not want to use the auto tuner.

Tuning in this section will focus on tuning in the time domain. This means that we will look

at the velocity or position response vs. time as the criteria we use to decide how well

tuned a control loop is tuned.

Determining Tuning Criteria

Choosing the proper specifications for a machine is a prerequisite for tuning. Unless you

have a clear understanding of the type of performance needed to push the machine into

production, the tuning process will cause more problems and headaches than it solves.

Take time to layout ALL the requirements of the machine—nothing is too trivial to

consider.

• Determine what the most important criteria are. The machine was likely

designed and developed with a certain performance in mind. Include ALL

performance criteria in the specification. Do not concern yourself with whether

or not the criteria sound scientific. (i.e. If the motion needs to visibly look

smooth, put it in the specification. If it can't have any noise, put it in the

specification.) At the end of the development phase, the machine's performance

should match the performance previously set in the specification. This will

ensure that the machine meets its performance goals and that it is ready for

production.

• Test the machine with realistic motion. Do not simply tune the machine to make

short linear motion, when it will make long, s-curve motions in the real world.

Unless you test the machine with realistic motion, there is no way to determine

if it is ready for production.

• Determine some specific, quantitative criteria for identifying unacceptable

motion. It's better to be able to tell when a motion is unacceptable than to try

and figure out the exact point where acceptable motion becomes unacceptable.

Here are some examples of motion criteria:

1. +/– x position error counts during the entire motion.

2. Settling within +/- x position error counts, within y milliseconds.

3. Velocity tolerance of x% measured over y samples.

• It is important to focus on the things that will get the machine into production

with reliable performance, based on a fundamental understanding of the

system.

http://kdn.kollmorgen.com/webhelp/workbench/English/Content/UsersManual/Tuning%20t