IEEE TRANSACTIONS ON ELECTRON DEVICES, VOL. 64, NO. 5, MAY 2017 1991

A High-Reliability Gate Driver Integrated in

Flexible AMOLED Display by IZO TFTs

Wei-Jing Wu,

Member, IEEE

, Li-Rong Zhang, Zhi-Ping Xu, Lei Zhou, Hao Tao,

Jian-Hua Zou, Miao Xu, Lei Wang, and Jun-Biao Peng

Abstract

— This paper presents a new gate driver

integrated by IZO thin-film transistors (TFTs) with the etch

stop layer structure on the polyimide substrate, which con-

sists of nine TFTs and two capacitors. There are several

advantages for the proposed gate driver, such as simple

circuitry, full-swing output, low power, and good reliability.

The proposed gate driver has been successfully integrated

in a flexible active matrix organic light emitting display with

the resolution of 200 (RGB) × 600, in which the conventional

2T1C pixel circuit with bottom-emission structure is used.

It is shown that there are no distortion and good noise-

suppressed characteristics for the output signals even up

to 600 stages. In addition, the proposed gate driver has a

good stability, since no voltage fluctuation occurs under

720-h test. Moreover, the flexible panel works well after a

10000 times repetitive bending performed on a test bench,

which is mainly composed of a programmed logic controller

and dc motor. During the bending test, the minimum curva-

ture radius of flexible panel can reach to be about 5 mm.

IndexTerms

— Flexibleactivematrixorganiclightemitting

display (AMOLED), gate driver, IZO thin-film transistors

(TFTs).

I. INTRODUCTION

F

LEXIBLE displays on a plastic substrate have received

much attention due to their superior characteristics, such

as thinner thickness, lighter weight, and bendability [1], [2].

The flexible active matrix organic light emitting dis-

play (AMOLED) is a very promising display technology

due to its all solid-state process [3]–[7]. To realize flexi-

ble AMOLED displays, it is mainly required to fabricate a

uniform and stable thin-film transistors (TFTs) backplane on

the flexible substrate. Low-temperature polycrystalline-silicon

Manuscript received December 15, 2016; accepted

December 15, 2016. Date of publication January 4, 2017; date of

current version April 19, 2017. This work was supported in part by

the 973 Program under Grant 2015CB655004 founded by the Ministry

of Science and Technology, in part by the National Natural Science

Foundation of China under Grant 61574062 and Grant 61574061,

and in part by the Science and Technology Program of Guangdong

Province under Grant 2016B090906002, Grant 2016B090907001,

Grant 2015B090914003, and Grant 2015B090915001. The review of

this paper was arranged by Editor M. M. Hussain.

(Corresponding

author: Wei-Jing Wu.)

W.-J. Wu, Z.-P. Xu, M. Xu, L. Wang, and J.-B. Peng are with the State

Key Laboratory of Luminescent Materials and Devices, South China Uni-

versity of Technology, Guangzhou 510640, China (wuwj@scut.edu.cn).

L.-R. Zhang, L. Zhou, H. Tao, and J.-H. Zou are with Guangzhou New

Vision Opto-Electronic Technology Co., Ltd., Guangzhou 510530, China.

Color versions of one or more of the figures in this paper are available

online at http://ieeexplore.ieee.org.

Digital Object Identifier 10.1109/TED.2016.2641448

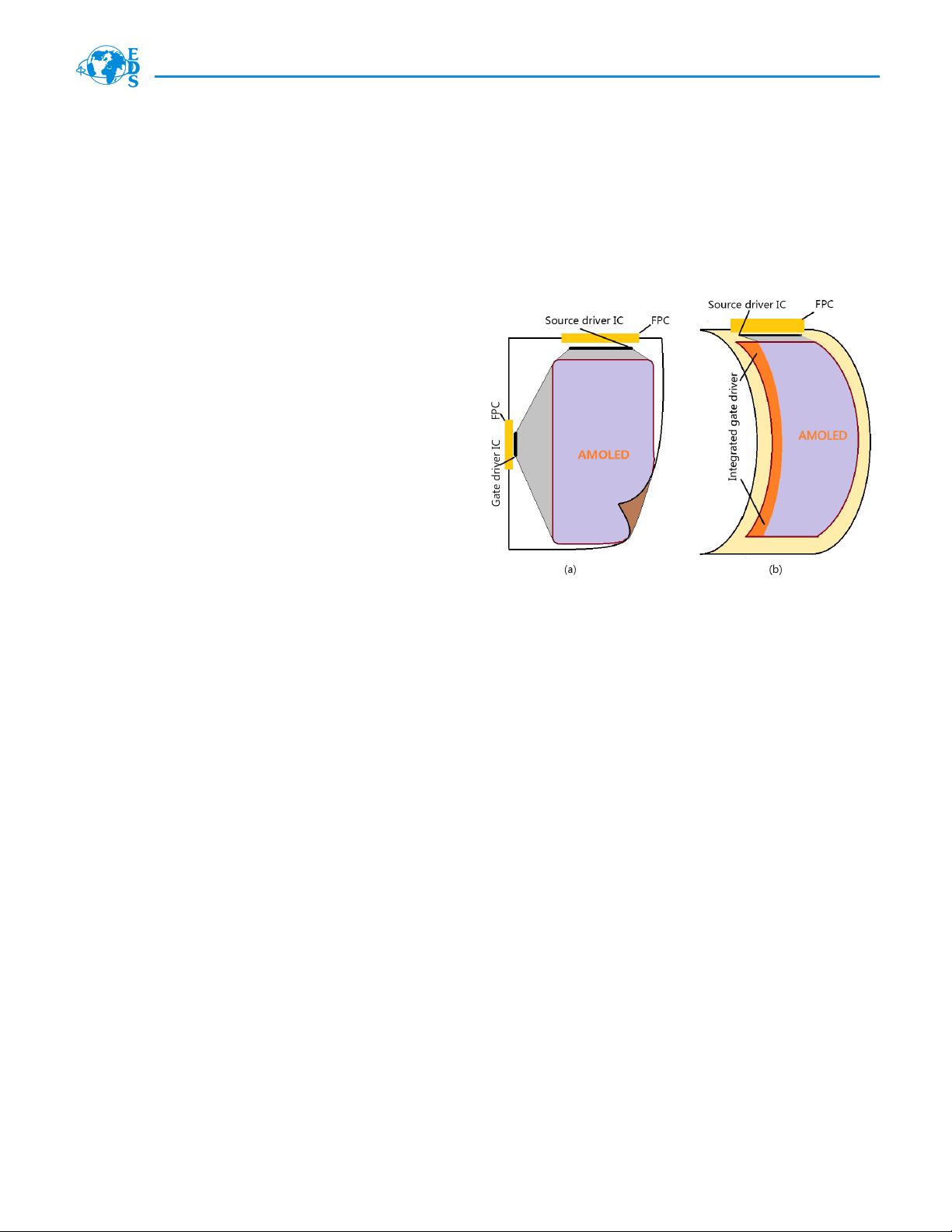

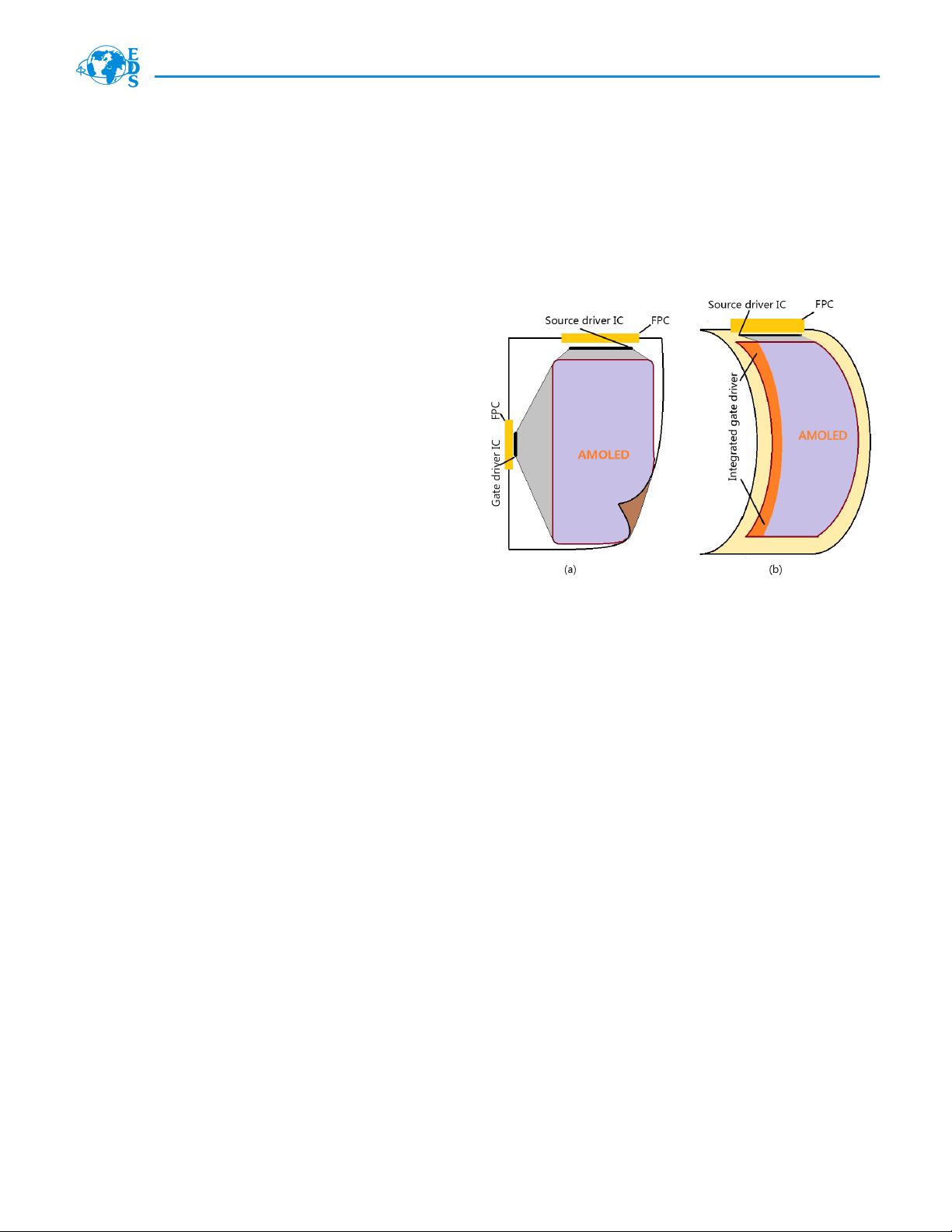

Fig. 1. (a) Display panel with source driver IC and gate driver IC.

(b) Flexible display panel with the integrated gate driver.

TFTs are widely used to drive OLED devices due to high

field-effect mobility [>50 cm

2

/(V · S)] and stable electrical

performance [8], [9]. However, there still exist the drawbacks

of poor uniformity over a large area and quite high process

temperature (400 °C–500 °C) during silicon crystallization.

In the recent years, metal oxide (MO) TFTs have attracted

considerable interest due to high mobility, low fabrication

temperature, good uniformity, good process compatibility with

a-Si:H TFTs, and the compatibility with transparent or flexible

applications [10]–[14]. Discrete flexible MO TFTs and their

simple circuits have been reported by several groups [15]–[20].

For active matrix displays, such as AMOLED or AMLCD,

source driver in the column direction and gate driver in the

row direction are needed. Conventionally, the source driver IC

and gate driver IC, packaged with tape automated bond or chip

on glass, are boned to display panel, as shown in Fig. 1(a).For

flexible displays, ICs are easy to strip from the plastic substrate

under the process of bending. Along with the development of

TFT technology, the gate driver is being tried to be integrated

on the same flexible display panel. However, source driver is

hard to be integrated by TFTs due to its complexity. Hence, the

flexible display panel can be freely bended in the row direction

with the integration of gate driver, as shown in Fig. 1(b).

As a result, integrating the gate driver in the flexible dis-

play can not only enhance the reliability but also lower the

fabrication cost. It is common that the gate driver is integrated

0018-9383 © 2017 IEEE. Personal use is permitted, but republication/redistribution requires IEEE permission.

See http://www.ieee.org/publications_standards/publications/rights/index.html for more information.