"大学生国赛化工东华科技杯-丙烷脱氢制丙烯项目安全环保介绍"

版权申诉

51 浏览量

更新于2024-02-24

收藏 9.18MB PPTX 举报

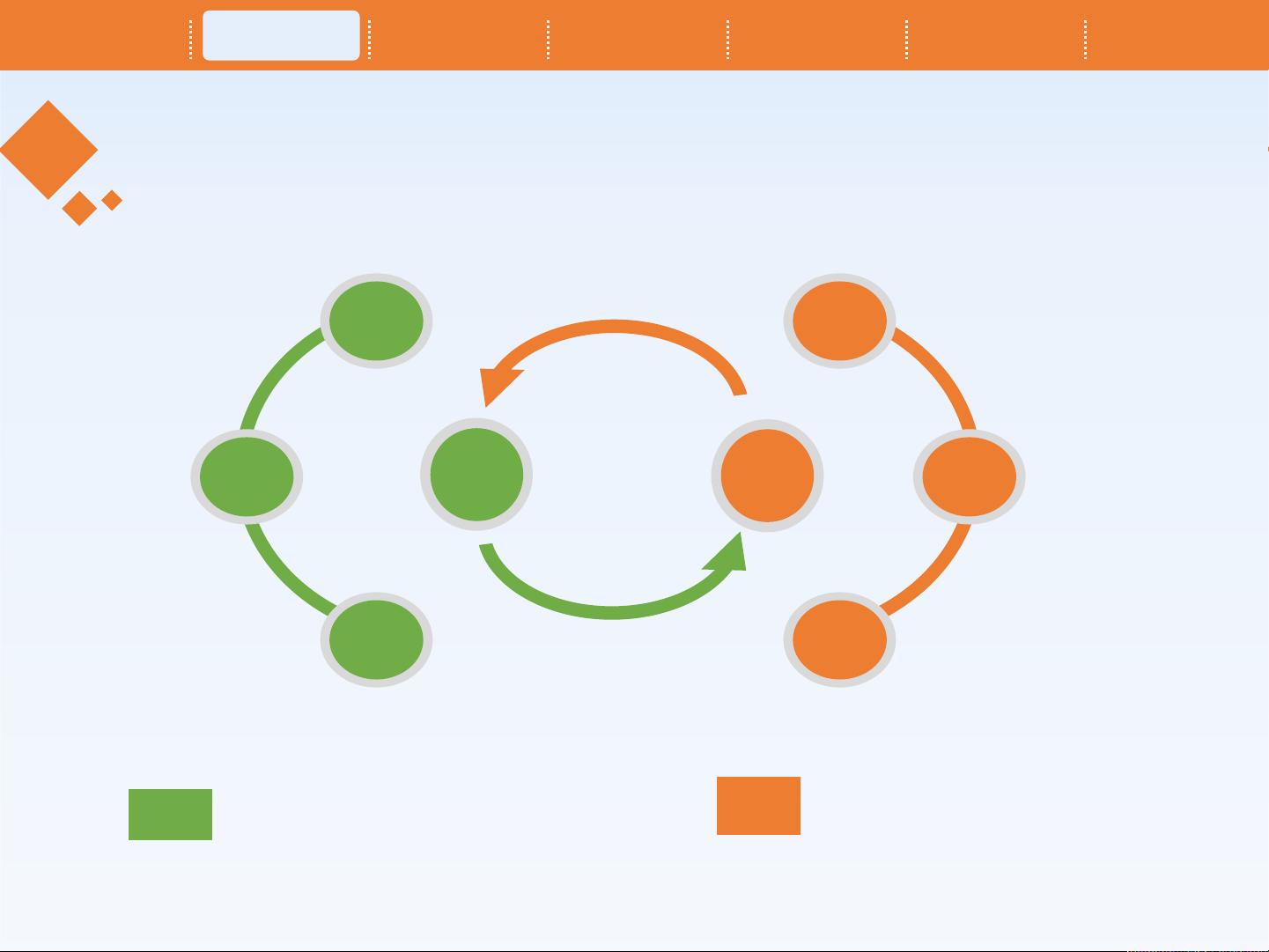

The presentation "大学生国赛化工东华科技杯-年产30万吨PDH-丙烷脱氢制丙烯生产项目介绍.pptx" provides an in-depth overview of the production project for propylene via propane dehydrogenation (PDH) with an annual capacity of 300,000 tons. The project aims to meet the increasing demand for propylene, a key chemical used in various industries such as plastic, synthetic fibers, and automotive. This project is part of the East China University of Science and Technology's participation in the national chemical engineering competition.

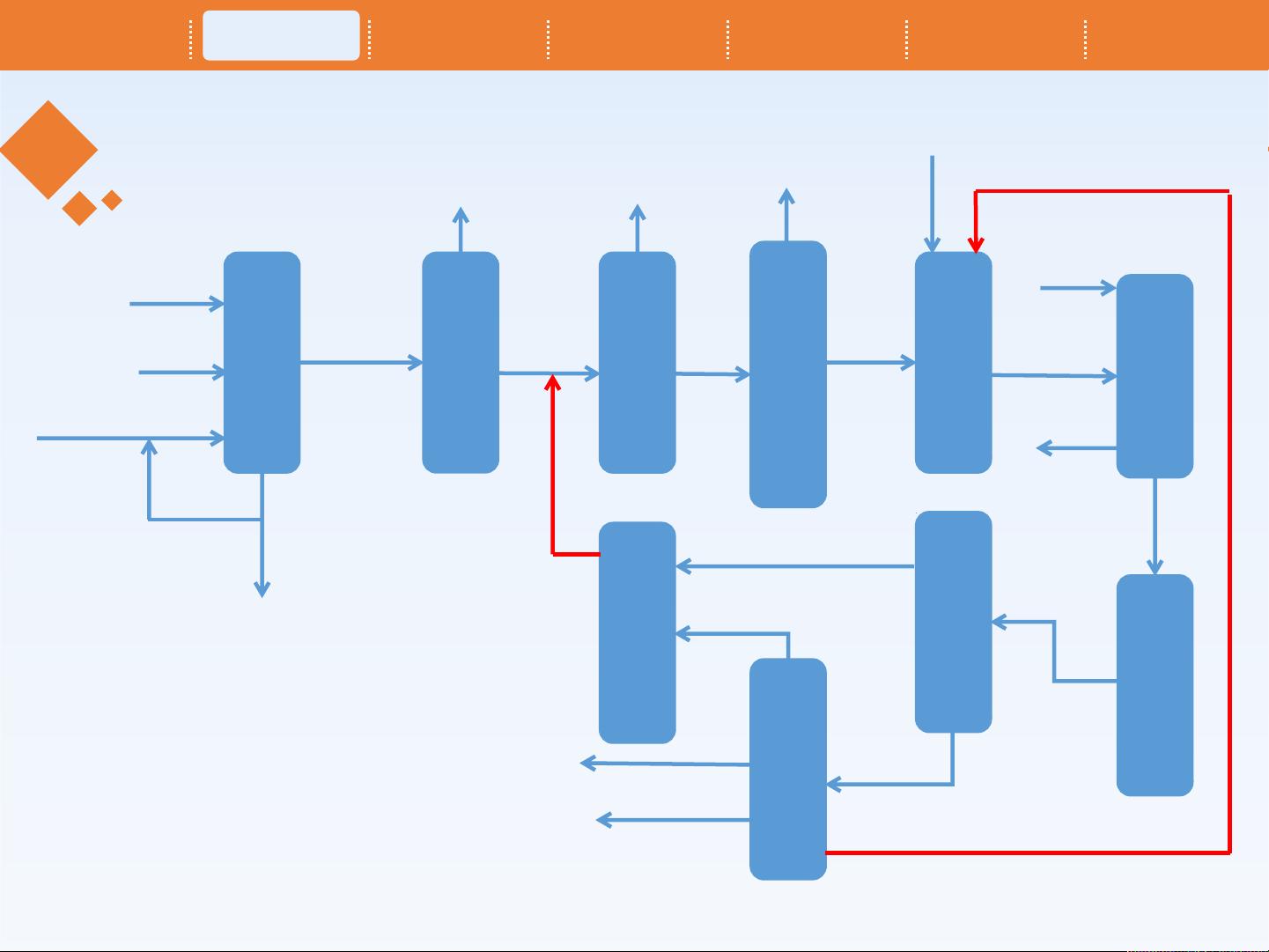

The presentation highlights the process flow, equipment layout, and key parameters of the PDH plant. It explains the chemical reactions involved in the conversion of propane to propylene, as well as the catalysts and reactors used in the process. The detailed design and engineering considerations for the project are also discussed, including heat and mass balances, process control, and energy efficiency measures.

One of the key focuses of the presentation is on the safety and environmental aspects of the project. Safety measures, such as process control systems, emergency shut-off valves, and fire detection systems, are outlined to ensure the protection of personnel and assets. Environmental considerations, such as waste management, emissions control, and energy consumption, are also addressed to minimize the impact of the production plant on the surrounding environment.

Overall, the presentation emphasizes the importance of implementing rigorous safety and environmental standards in the design and operation of chemical production projects. By integrating advanced technologies and best practices, the PDH plant aims to achieve high efficiency, reliability, and sustainability while meeting the growing demand for propylene in the market. The project not only demonstrates the technical expertise of the university students but also their commitment to responsible and sustainable practices in the chemical industry.

2023-12-18 上传

2023-12-18 上传

2023-12-18 上传

2023-06-06 上传

2023-06-06 上传

2023-12-28 上传

2023-06-13 上传

2023-05-12 上传

2023-04-21 上传

2023-06-06 上传

心兰相随引导者

- 粉丝: 1105

- 资源: 5639

最新资源

- 深入浅出:自定义 Grunt 任务的实践指南

- 网络物理突变工具的多点路径规划实现与分析

- multifeed: 实现多作者间的超核心共享与同步技术

- C++商品交易系统实习项目详细要求

- macOS系统Python模块whl包安装教程

- 掌握fullstackJS:构建React框架与快速开发应用

- React-Purify: 实现React组件纯净方法的工具介绍

- deck.js:构建现代HTML演示的JavaScript库

- nunn:现代C++17实现的机器学习库开源项目

- Python安装包 Acquisition-4.12-cp35-cp35m-win_amd64.whl.zip 使用说明

- Amaranthus-tuberculatus基因组分析脚本集

- Ubuntu 12.04下Realtek RTL8821AE驱动的向后移植指南

- 掌握Jest环境下的最新jsdom功能

- CAGI Toolkit:开源Asterisk PBX的AGI应用开发

- MyDropDemo: 体验QGraphicsView的拖放功能

- 远程FPGA平台上的Quartus II17.1 LCD色块闪烁现象解析