.NET OPC UA-Client

Entry-ID: 42014088, V1.2, 12/2017

Copyright Siemens AG 2017 All rights reserved

3 Basics

3.1 Basics on OPC

Overview

In recent years, the OPC Foundation (an interest group of well-known

manufacturers for the definition of standard interfaces) has defined a large number

of software interfaces to standardize the information flow from the process level to

the management level. According to the different requirements within an industrial

application, different OPC specifications have been developed in the past: Data

Access (DA), Alarm & Events (A&E), Historical Data Access (HDA) and Data

eXchange (DX). Access to process data is described in the DA specification, A&E

describes an interface for event-based information, including acknowledgement,

HDA describes functions for archived data and DX defines a lateral server to server

communication.

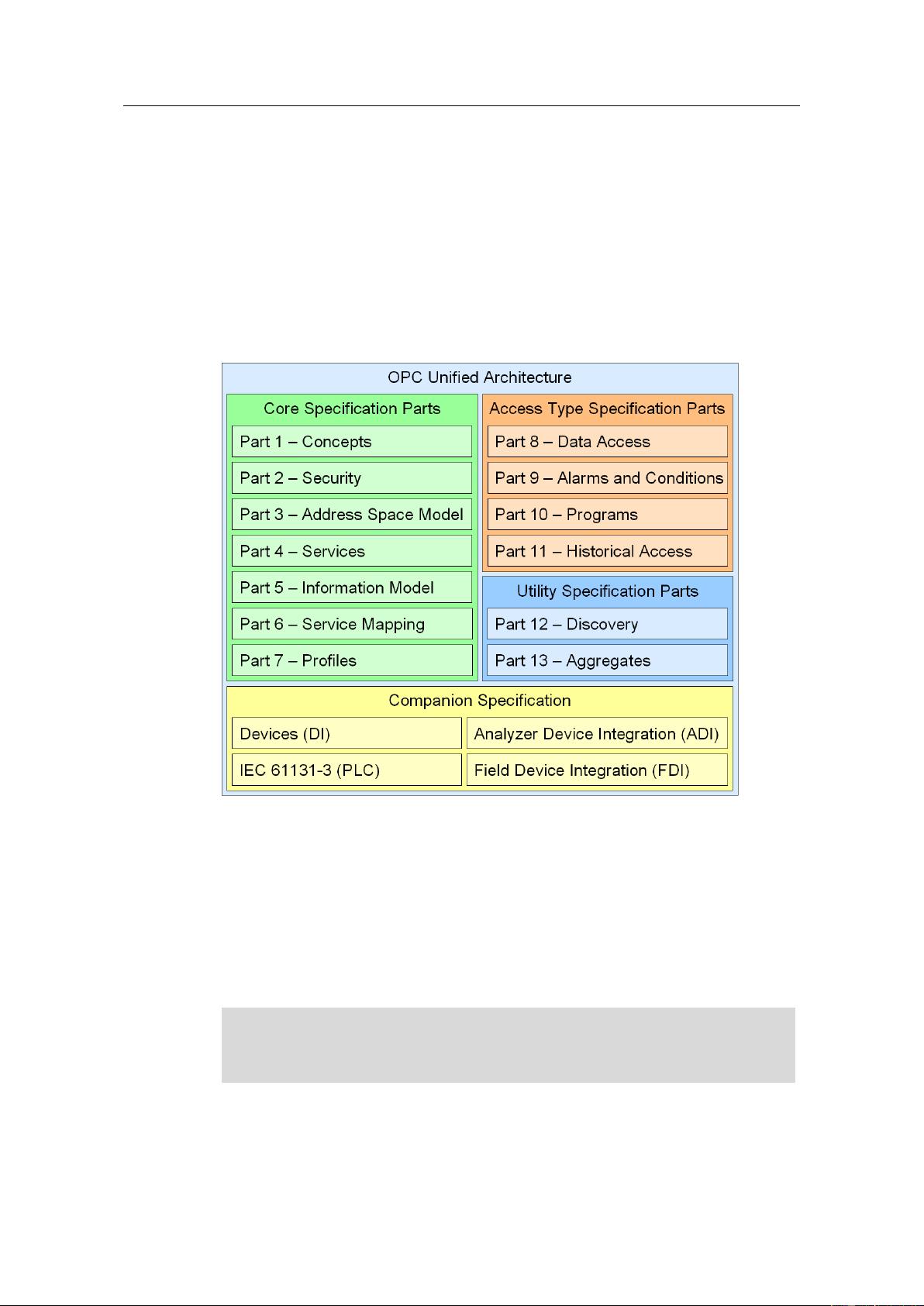

Based on the experience with these classic OPC interfaces, the OPC Foundation

defined a new platform, called OPC Unified Architecture (UA). The aim of this new

standard is the generic description and uniform access to all information which is to

be exchanged between systems or applications. This includes the functionality of

all previous OPC interfaces. Furthermore, it is to generate the possibility of natively

integrating the interface in the respective system, irrespective of which operating

system the system is operated on and irrespective of the programming language in

which the system was created.

This example discusses the OPC Unified Architecture interface. A detailed

documentation is available on the SIMATIC NET CD. For more information, please

go to www.opcfoundation.org.

What is OPC?

In the past, OPC was a collection of software interfaces for data exchange between

PC applications and process devices. These software interfaces have been defined

according to the rules of Microsoft COM (Component Object Model) and can

therefore be easily integrated into Microsoft operating systems. COM or DCOM

(Distributed COM) provides the functionality of inter process communication and

organizes the information exchange between applications, even across network

boundaries (DCOM). Using mechanisms of the Microsoft operating system, an

OPC client (COM client) can use it to exchange information with an OPC server

(COM server).

The OPC server provides process information of a device at its interface. The OPC

client connects itself with the OPC server and can access the offered data.

The use of COM or DCOM causes OPC servers and clients to run only on a

Windows PC or in the local network and that the communication to the respective

automation system has to be realized mainly via proprietary protocols. Additional

tunneling tools often have to be used for the network communication between

client and server in order to get through firewalls or to avoid the complicated

DCOM configuration. The interface can furthermore only be accessed natively with

C++ applications; .NET or JAVA applications can only gain access via a wrapper

layer. In real-life situations, these restrictions lead to additional communication and

software layers which increase the configuration workload and the complexity.

Due to the widespread use OPC, the standard is increasingly used for the general

connection of automation systems and no longer only for the original application as

driver interface in HMI and SCADA systems to access process information.