September 10, 2006 / Vol. 4, No. 9 / CHINESE OPTICS LETTERS 525

Compact extended cavity diode laser system for small

optically pumpe d cesium beam frequency standards

Jianwei Zhang (

), Kaikai Huang (

), and Donghai Yang (

üüü

)

Key Laboratory for Quantum Information and Measurement, Ministry of Education,

School of Electronics Engineering & Computer Science, Peking Universit y, Beijing 100871

Received May 24, 2006

A compact extended cavity diode laser (ECDL) system operating at 852 nm for small optically pumped

cesium (Cs) beam frequency standards was reported. ECDL and a saturated absorption spectroscopy setup

w ere all built in an aluminum box with dimension of 10 × 10 × 7 (cm). ECDL wa s based on a Littman-

Metcaff configuration, whose free-running linewidth was less than 600 kHz. A digital automatic frequency

lock unit (AFLU) was developed to lock the laser frequency to specify Cs absorption lines automatically

and re-lock it in case of lock broken. With AFLU, the laser frequency was continuously locked for several

weeks.

OCIS codes: 140.2020, 300.6460, 120.4570.

In the past decades, many laboratory efforts were made

in the development of small optically pumped cesium

(Cs) frequency standards

[1−6]

. One of the main chal-

lenges to construct a compact and portable optically

pumped Cs clock is to develop a compact, low noise,

narrow linewidth, and long lifetime laser system whose

frequency keeps being locked on a certain Cs atomic tran-

sition line stably for a reasonably long time. Besides, as

a pa rt of equipment, the laser system should be able to

work hands off.

Our laboratory has developed several versions of com-

pact laser systems for compact optically pumped Cs

beam clocks

[7]

, and they worked very well

[1]

.Thelaser

diodes (LDs) used in these laser systems were distributed

Bragg reflection (DBR) type. As a result, the linewidth

of these laser systems, about tens of megahertz, is not

narrow enough for optically pumped Cs clock with right

angle incidence of probing laser b eam

[8]

.Whatismore,

as far as we know, no commercial DBR LDs at 852

nm with linewidth below 1 MHz are available so far.

Therefore, we use extended cavity diode lasers (ECDLs),

with compact volume and narrow linewidth, to take the

place of DBR LDs. Many groups have developed their

compact ECDLs

[9−16]

, many of which were designed

based on Littrow configuration. Though the Littrow

configuration is relatively simple, the direction of laser

beam changes o r shifts as the grating rotates for tuning

the laser wavelength

[12]

, which will bring troubles in ex-

periments.

In this letter, we report a compact ECDL system for

small optically pumped Cs clocks, whose mechanical

design based on the Littman-Metcaff configuration is

simple: only the length of the extended cavity can be ad-

justed by piezoelectric transducer (PZT) when the laser

operates. To lock laser frequency, a Doppler-free sat-

urated absorption (SA) sp ectroscopy setup

[9]

was built

in the same aluminum box with ECDL. Additionally, in

order to realize long-term locking and hands off work-

ing, we developed a digital automatic frequency lock

unit (AFLU) to control the laser op erating parameters

(temperature, current, and piezovoltage). AFLU is an

improved simpler version of the automatic laser fre-

quency lock device in Ref. [7]. Though other group also

developed automatic laser frequency lock system

[7]

,our

work is simple than them.

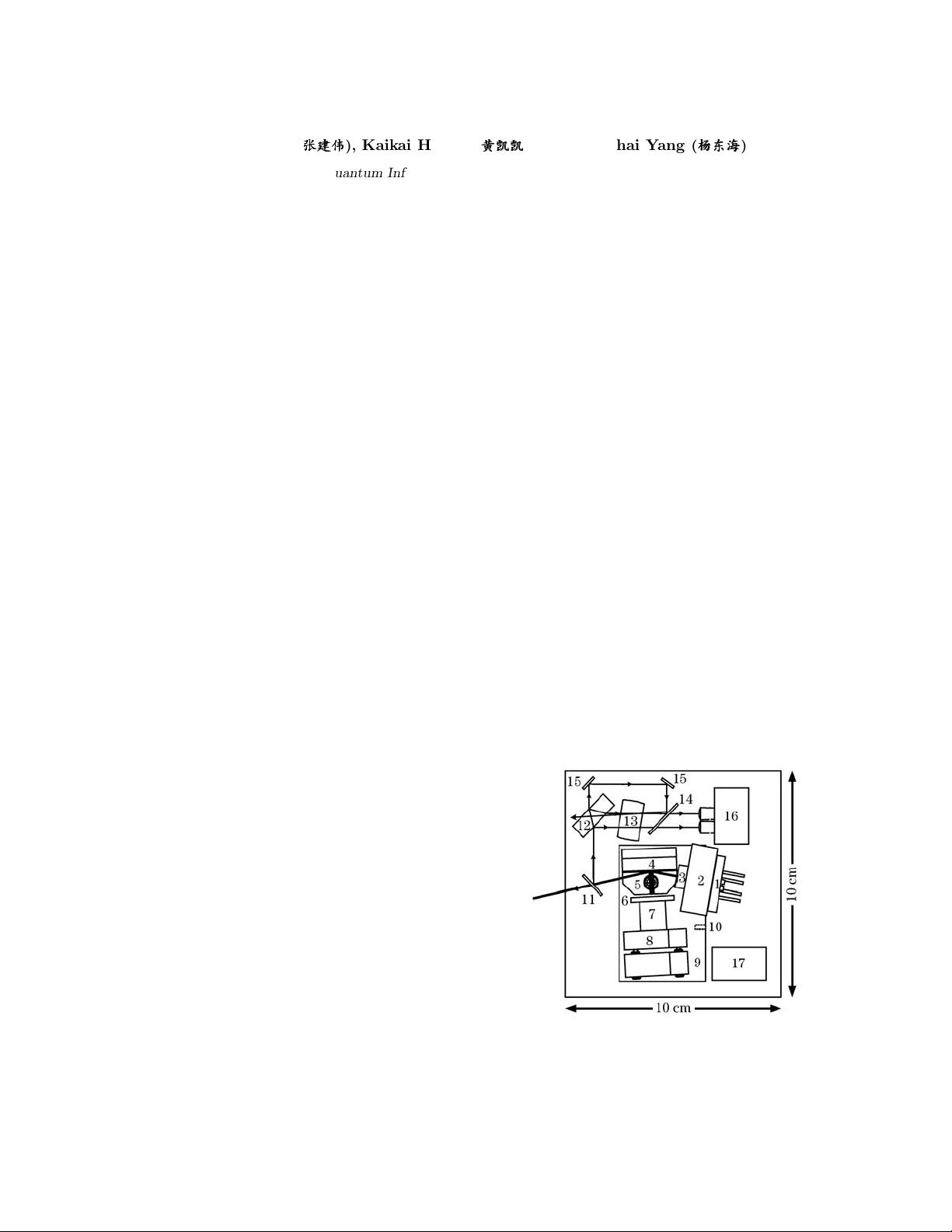

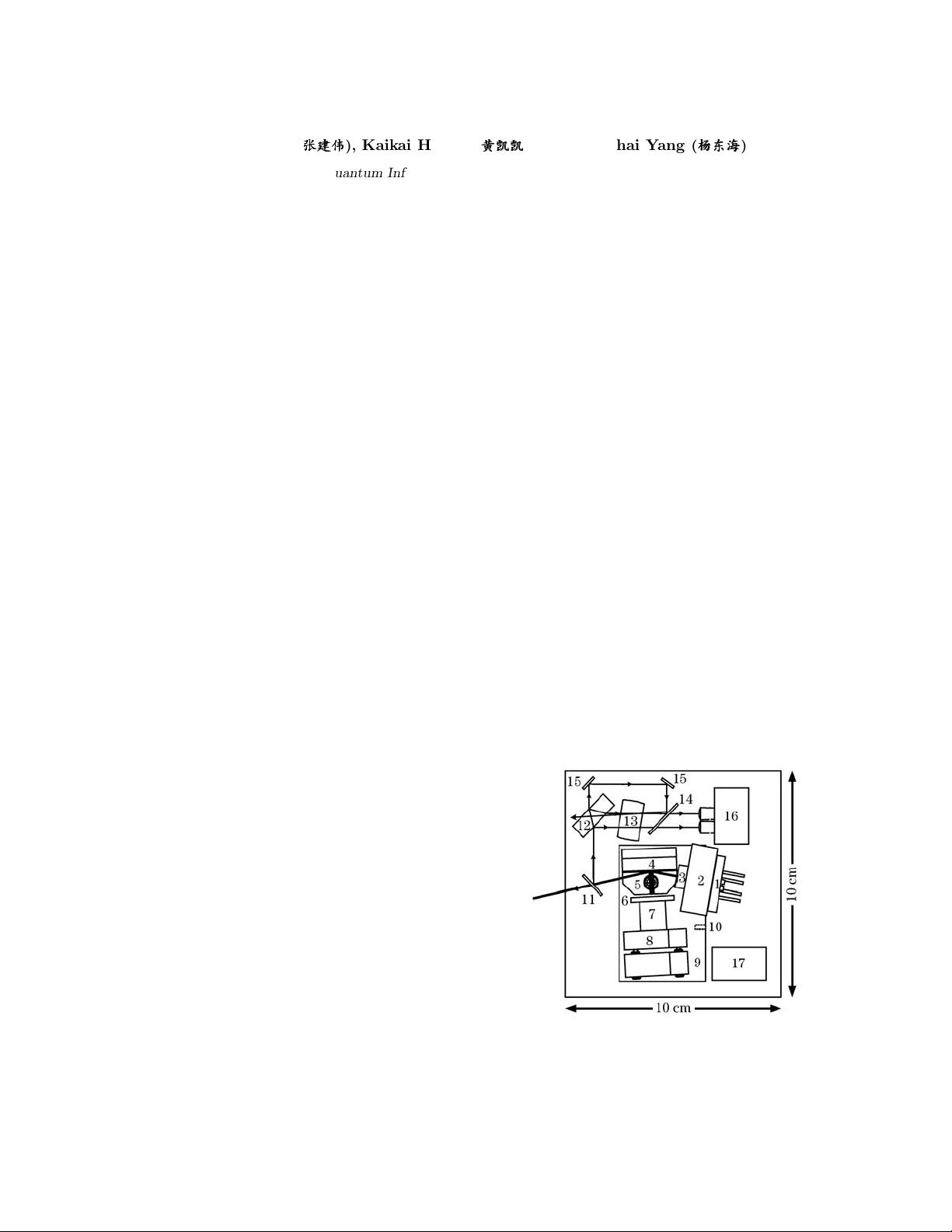

Figure 1 shows the schematic of the laser head, con-

sisting of an E CDL (lower part) and a reference spec-

troscopy setup (upper part). The LD is an AlGaAs

diode (JDS Uniphase SDL 5412-H1) without additional

antireflection (AR) coating. The diffraction grating, a

1200-line/mm holographic grating, was fixed on a grat-

ing mount. The incident angle of the laser beam on

the grating was about 80

◦

, and the laser polarization

direction was perpendicular to the grooves. The first-

order diffraction beam of the grating was reflected by

amirrorfixedonaPZTtubewhichwasmountedona

mirror mount (ThorLabs KS05). The laser diode mount,

the grating mount and the mirror mount were all fixed

on a base plate, which was temperature stabilized by a

Fig. 1. Schematic of the laser head. 1: Laser diode, 2: laser

diode and collimating lens mounting block, 3: collimating

lens, 4: diffraction grating, 5: grating mount, 6: mirror, 7:

PZT, 8: mirror mount, 9: ECDL base plate, 10: thermis-

tor, 11: beam splitter, 12: thick glass, 13: Cs gas cell, 14:

1:1 beam splitter, 15: mirror, 16: subtraction photodiodes

detector, 17: laser diode protection circuit.

1671-7694/2006/090525-04 http://www.col.org.cn