17

TMS320C28346

,

TMS320C28345

,

TMS320C28344

TMS320C28343, TMS320C28342, TMS320C28341

www.ti.com.cn

ZHCSA18E –MARCH 2009–REVISED AUGUST 2018

Submit Documentation Feedback

Product Folder Links: TMS320C28346 TMS320C28345 TMS320C28344 TMS320C28343 TMS320C28342

TMS320C28341

Terminal Configuration and FunctionsCopyright © 2009–2018, Texas Instruments Incorporated

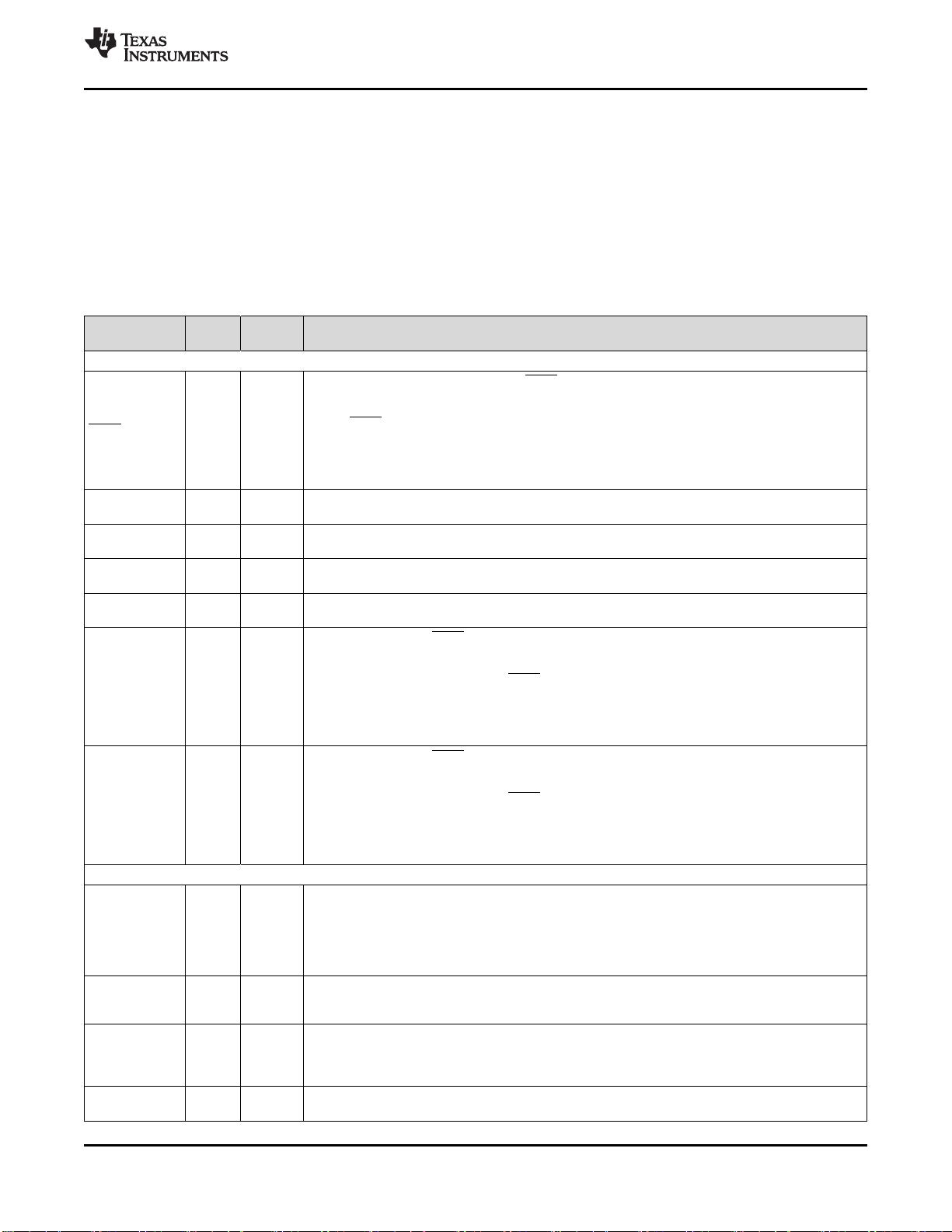

4.2 Signal Descriptions

Table 4-1 describes the signals. The GPIO function (shown in Italics) is the default at reset. The peripheral

signals that are listed under them are alternate functions. Some peripheral functions may not be available

in all devices. See Table 3-1 for details. Inputs are not 5-V tolerant. All XINTF pins have a drive strength

of 4 mA (typical). All GPIO pins are I/O/Z, 4-mA drive typical and have an internal pullup, which can be

selectively enabled or disabled on a per-pin basis. This feature only applies to the GPIO pins. The pullups

on GPIO0–GPIO11 and GPIO58–GPIO63 pins are not enabled at reset. The pullups on GPIO12–GPIO57

and GPIO64–GPIO87 are enabled upon reset.

Table 4-1. Signal Descriptions

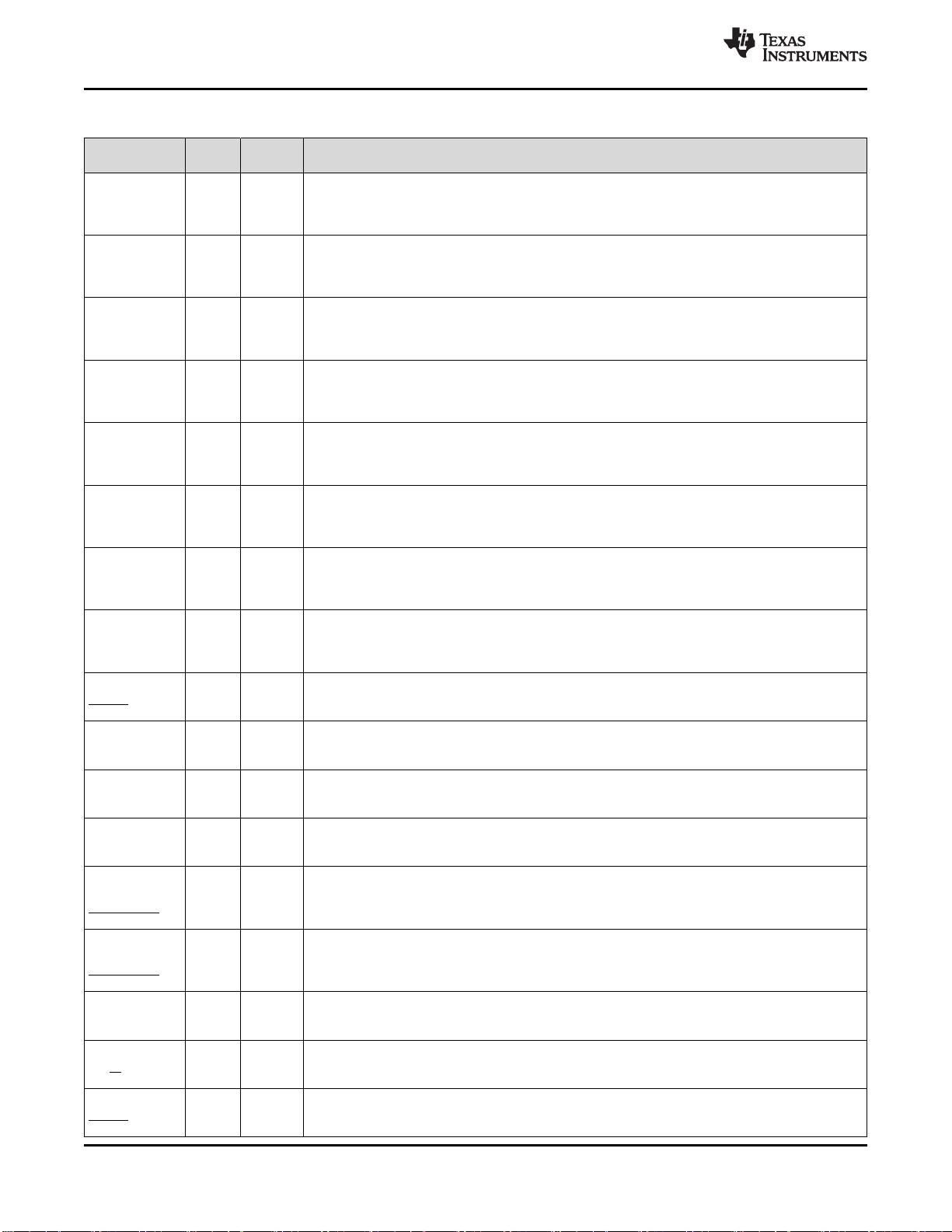

NAME

ZHH

BALL #

ZFE

BALL #

DESCRIPTION

JTAG

TRST M7 R8

JTAG test reset with internal pulldown. TRST, when driven high, gives the scan system control of

the operations of the device. If this signal is not connected or driven low, the device operates in its

functional mode, and the test reset signals are ignored.

NOTE: TRST is an active high test pin and must be maintained low at all times during normal

device operation. An external pulldown resistor is recommended on this pin. The value of this

resistor should be based on drive strength of the debugger pods applicable to the design. A 2.2-kΩ

resistor generally offers adequate protection. Because this is application-specific, TI recommends

validating each target board for proper operation of the debugger and the application. (I, ↓)

TCK P9 T11

JTAG test clock. An external pullup resistor is required on this pin. A 2.2-kΩ resistor generally offers

adequate protection.(I)

TMS M8 P9

JTAG test-mode select (TMS) with internal pullup. This serial control input is clocked into the TAP

controller on the rising edge of TCK. (I, ↑)

TDI L6 T8

JTAG test data input (TDI) with internal pullup. TDI is clocked into the selected register (instruction

or data) on a rising edge of TCK. (I, ↑)

TDO N7 P8

JTAG scan out, test data output (TDO). The contents of the selected register (instruction or data)

are shifted out of TDO on the falling edge of TCK.

EMU0 N9 P10

Emulator pin 0. When TRST is driven high, this pin is used as an interrupt to or from the emulator

system and is defined as input/output through the JTAG scan. This pin is also used to put the

device into boundary-scan mode. With the EMU0 pin at a logic-high state and the EMU1 pin at a

logic-low state, a rising edge on the TRST pin would latch the device into boundary-scan mode.

NOTE: An external pullup resistor is recommended on this pin. The value of this resistor should be

based on the drive strength of the debugger pods applicable to the design. A 2.2-kΩ to 4.7-kΩ

resistor is generally adequate. Because this is application-specific, TI recommends validating each

each target board for proper operation of the debugger and the application.

EMU1 L9 R10

Emulator pin 1. When TRST is driven high, this pin is used as an interrupt to or from the emulator

system and is defined as input/output through the JTAG scan. This pin is also used to put the

device into boundary-scan mode. With the EMU0 pin at a logic-high state and the EMU1 pin at a

logic-low state, a rising edge on the TRST pin would latch the device into boundary-scan mode.

NOTE: An external pullup resistor is recommended on this pin. The value of this resistor should be

based on the drive strength of the debugger pods applicable to the design. A 2.2-kΩ to 4.7-kΩ

resistor is generally adequate. Because this is application-specific, TI recommends validating each

target board for proper operation of the debugger and the application.

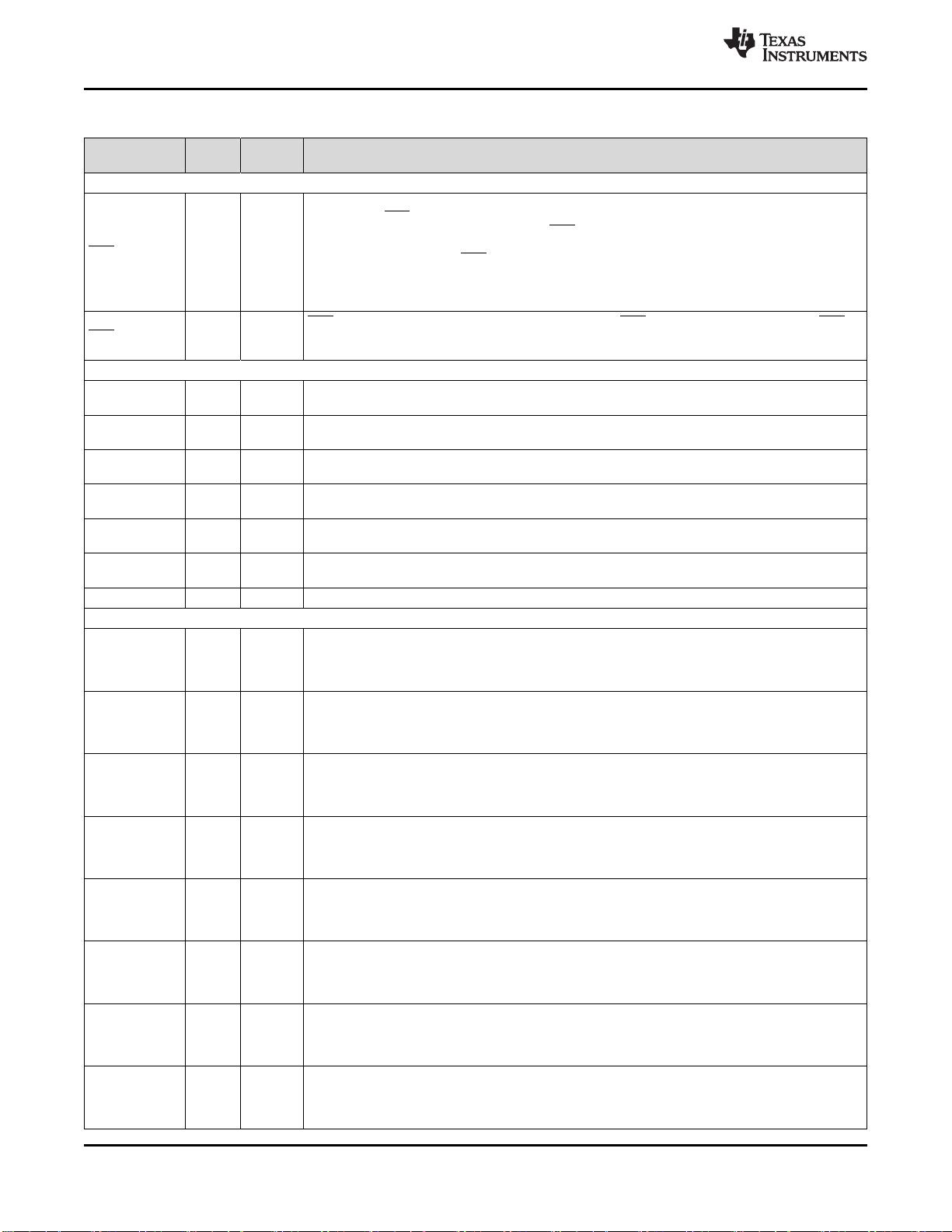

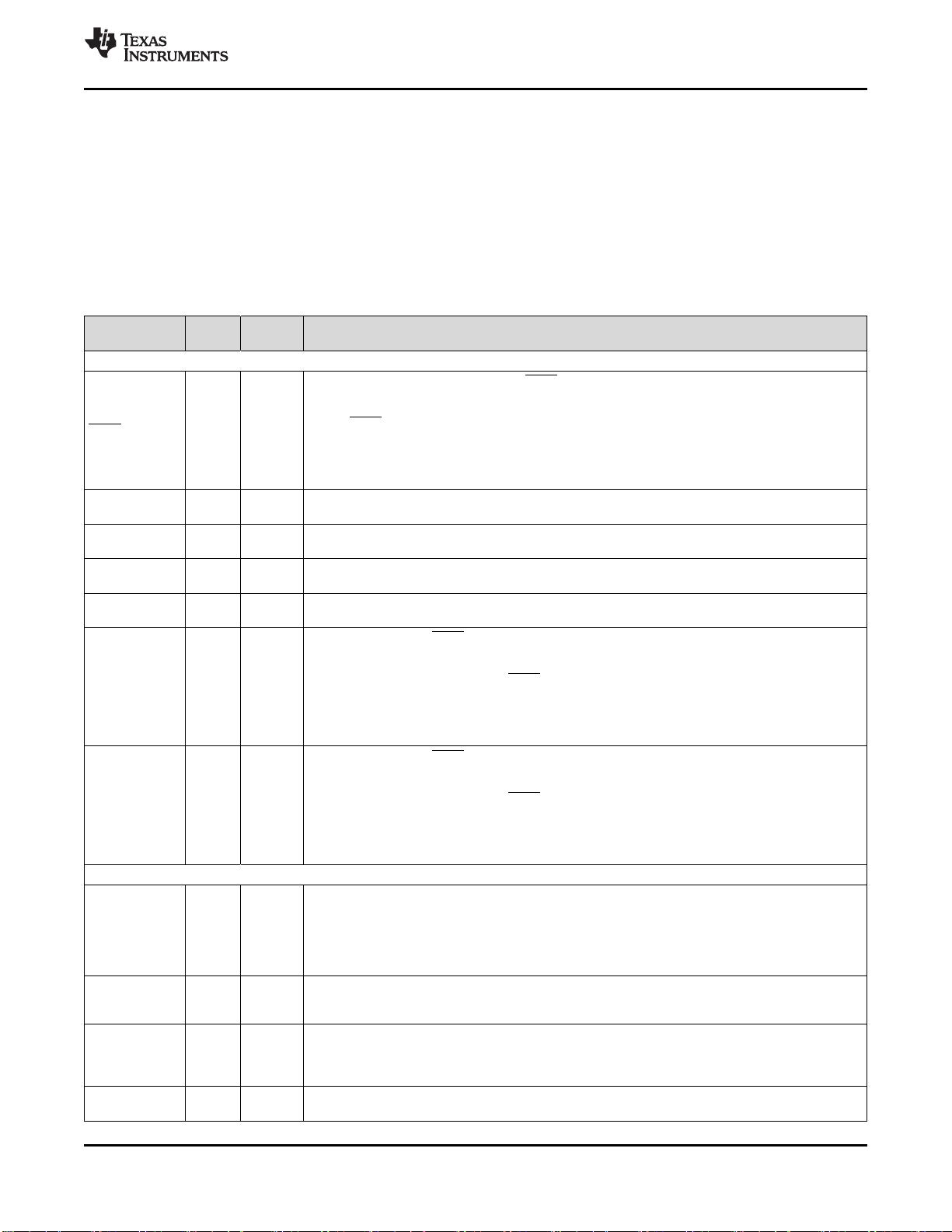

Clock

XCLKOUT B14 D16

Output clock derived from SYSCLKOUT. XCLKOUT is either the same frequency, one-half the

frequency, one-fourth the frequency, or one-eighth the frequency of SYSCLKOUT. This is controlled

by bit 19 (BY4CLKMODE), bits 18:16 (XTIMCLK), and bit 2 (CLKMODE) in the XINTCNF2 register.

At reset, XCLKOUT = SYSCLKOUT/8. The XCLKOUT signal can be turned off by setting

XINTCNF2[CLKOFF] to 1. Unlike other GPIO pins, the XCLKOUT pin is not placed in high-

impedance state during a reset.

XCLKIN D9 A12

External Oscillator Input. This pin is to feed a clock from an external 3.3-V oscillator. In this case,

the X1 pin must be tied to V

SSK

. If a crystal/resonator is used (or if an external 1.8-V oscillator is

used to feed clock to X1 pin), this pin must be tied to V

SS

. (I)

X1 C8 A7

Internal/External Oscillator Input. To use the internal oscillator, a quartz crystal may be connected

across X1 and X2. The X1 pin is referenced to the 1.8-V core digital power supply. A 1.8-V external

oscillator may be connected to the X1 pin. In this case, the XCLKIN pin must be connected to V

SS

.

If a 3.3-V external oscillator is used with the XCLKIN pin, X1 must be tied to V

SSK

. (I)

X2 A8 A9

Internal Oscillator Output. A quartz crystal may be connected across X1 and X2. If X2 is not used it

must be left unconnected. (O)