数控加工工艺:凹圆弧多配合综合件的设计与程序编制【摘要】

版权申诉

67 浏览量

更新于2024-04-04

收藏 1.2MB DOCX 举报

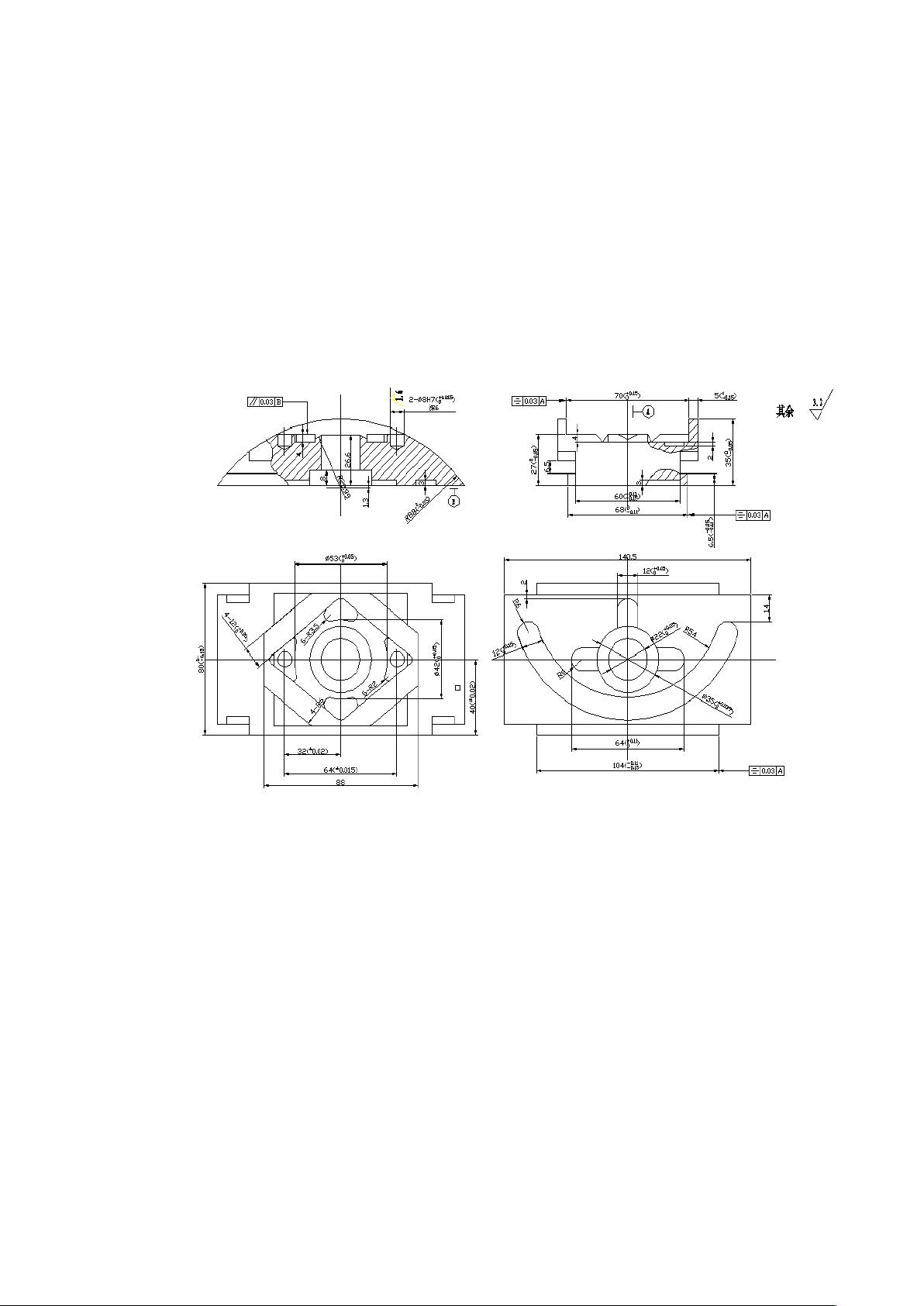

This paper focuses on the CNC machining process and programming of concave arc more comprehensive coordination. The research is based on the implementation of fixture clamping using milling arcs and precision flat-jaw clamps on the FANUC Series-0i-MC. Various cutting tools such as end mills, ball end mills, high-speed steel drill bits, high-speed steel reamers, and solid carbide thread mills are used to machine the parts in order to achieve multiple fits.

After reviewing relevant literature and references, the technical characteristics, geometric shapes, dimensions, and process requirements of the concave arc more comprehensive coordination parts are analyzed. The machining content and requirements are clarified, and the machining plan is determined. With the guidance and assistance of the instructor, a machining process that meets the requirements of the comprehensive part is designed, and a concise and convenient machining program is developed. The feasibility of the design is verified through simulation machining on a virtual machine tool.

The key elements of this research include multiple fits, machining process design, macro programming, right-hand threads, and concave arcs. This study provides valuable insights into the CNC machining process and programming of complex parts, and demonstrates the importance of meticulous planning and execution in achieving successful machining operations.

2022-02-06 上传

2023-09-15 上传

2022-11-18 上传

2023-09-16 上传

2021-09-27 上传

2023-07-08 上传

南抖北快东卫

- 粉丝: 80

- 资源: 5587

最新资源

- 全国江河水系图层shp文件包下载

- 点云二值化测试数据集的详细解读

- JDiskCat:跨平台开源磁盘目录工具

- 加密FS模块:实现动态文件加密的Node.js包

- 宠物小精灵记忆配对游戏:强化你的命名记忆

- React入门教程:创建React应用与脚本使用指南

- Linux和Unix文件标记解决方案:贝岭的matlab代码

- Unity射击游戏UI套件:支持C#与多种屏幕布局

- MapboxGL Draw自定义模式:高效切割多边形方法

- C语言课程设计:计算机程序编辑语言的应用与优势

- 吴恩达课程手写实现Python优化器和网络模型

- PFT_2019项目:ft_printf测试器的新版测试规范

- MySQL数据库备份Shell脚本使用指南

- Ohbug扩展实现屏幕录像功能

- Ember CLI 插件:ember-cli-i18n-lazy-lookup 实现高效国际化

- Wireshark网络调试工具:中文支持的网口发包与分析