ZnO-NANOWIRES COATED WITH GAMMA-ORDERED MESOPOROUS

ALUMINA (GAMMA-OMA) CATALYST FOR DETECTION OF FREON

Pengcheng Xu, Ying Chen, and Xinxin Li

State Key Lab of Transducer Technology, Shanghai Institute of Microsystem and Information

Technology, Chinese Academy of Sciences, 865 Changning Road, Shanghai 200050, CHINA

ABSTRACT

In this work, gamma-phase ordered mesoporous

alumina (J-OMA) is used as key catalyst to realize the

sensitive detection of Freon R134a with ZnO micro-sensor.

Due to the inert characteristic, Freon R134a (CH

2

FCF

3

) is

difficult to be detected by using conventional oxide

semiconductor gas sensors. J-OMA catalyst exhibits

satisfied active to R134a and produces several kinds of

active radicals. The ZnO nanowire (ZnO NW) sensor is

sensitive to the highly active radicals. The kinds of radicals

are qualitative identified by mass spectrum (MS) and the

J-OMA catalyst-enhanced sensing mechanism is clearly

elucidated.

INTRODUCTION

In the past decades, metal oxide semiconductors such

as tin dioxide (SnO

2

), zinc oxide (ZnO) and indium oxide

(In

2

O

3

) are widely used as sensing materials for

gases/vapors detection [1-4]. By using metal oxide sensing

materials, various kinds of gases/vapors including alcohol,

ketone, carbon monoxide (CO), hydrogen sulfide (H

2

S),

ammonia, and nitrogen dioxide (NO

2

) can be detected. The

universally accepted sensing mechanism between metal

oxide sensing material and target molecules is based on

gas-solid reaction, i.e. the target molecules react with the

adsorbing oxygen species (such as O

2

-

) at the surface of

metal oxide and thereafter, release/capture electrons

to/from the metal oxide sensing material [5]. The electron

releasing/capturing process brings a detectable sensing

signal of resistance change ('R%DVHGRQWKH³gas-solid

reaction´VHQVLQJPHFKDQLVPLWLVGLIILFXOWIRUPHWDOR[LGH

sensors detecting some inert molecules like Freon because

the inert molecule of Freon hardly reacts with the

adsorbing oxygen species without any catalysts.

As a kind of halogenated hydrocarbons, Freon is

widely used as refrigerant in many fields such as domestic

refrigeration and air conditioning. Recognized that the

chlorine contained Freon (i.e. chlorofluorocarbons) has the

negative environmental impacts such as destruction of

stratospheric ozone, Freon of chlorofluorocarbons is

banned in many countries to date. Currently, a new

generation of Freon (hydrochloroflurocarbons, HCFCs)

which features environment friendly characteristic has

been developed. Although it has almost none damage

effect to ozone layer, Freon HCFCs can cause global

warming. In addition, the leakage of Freon HCFCs

decreases the cooling effect of refrigerator which may

cause other problems. For example, one of the typical

Freon HCFCs of R134a (CH

2

FCF

3

) is widely applied in

cold chain industry. In this application field, avoiding

Freon R134a leakage in vehicle is helpful to guarantee the

freshness of the food during the long distance

transportation process. Hence, it is meaningful to real-time

detect low concentration Freon R134a. As is illustrated in

Fig.1, fluorine-contained compound of R134a (CH

2

FCF

3

)

is chemically inert and it cannot directly react with the

adsorbing oxygen species at the surface of metal oxide

sensing material. Thus, it is difficult to detect the leakage

of Freon R134a by using the conventional oxide

semiconductor gas sensors. Developing new catalyst plays

as a key role during the design process of R134a sensors.

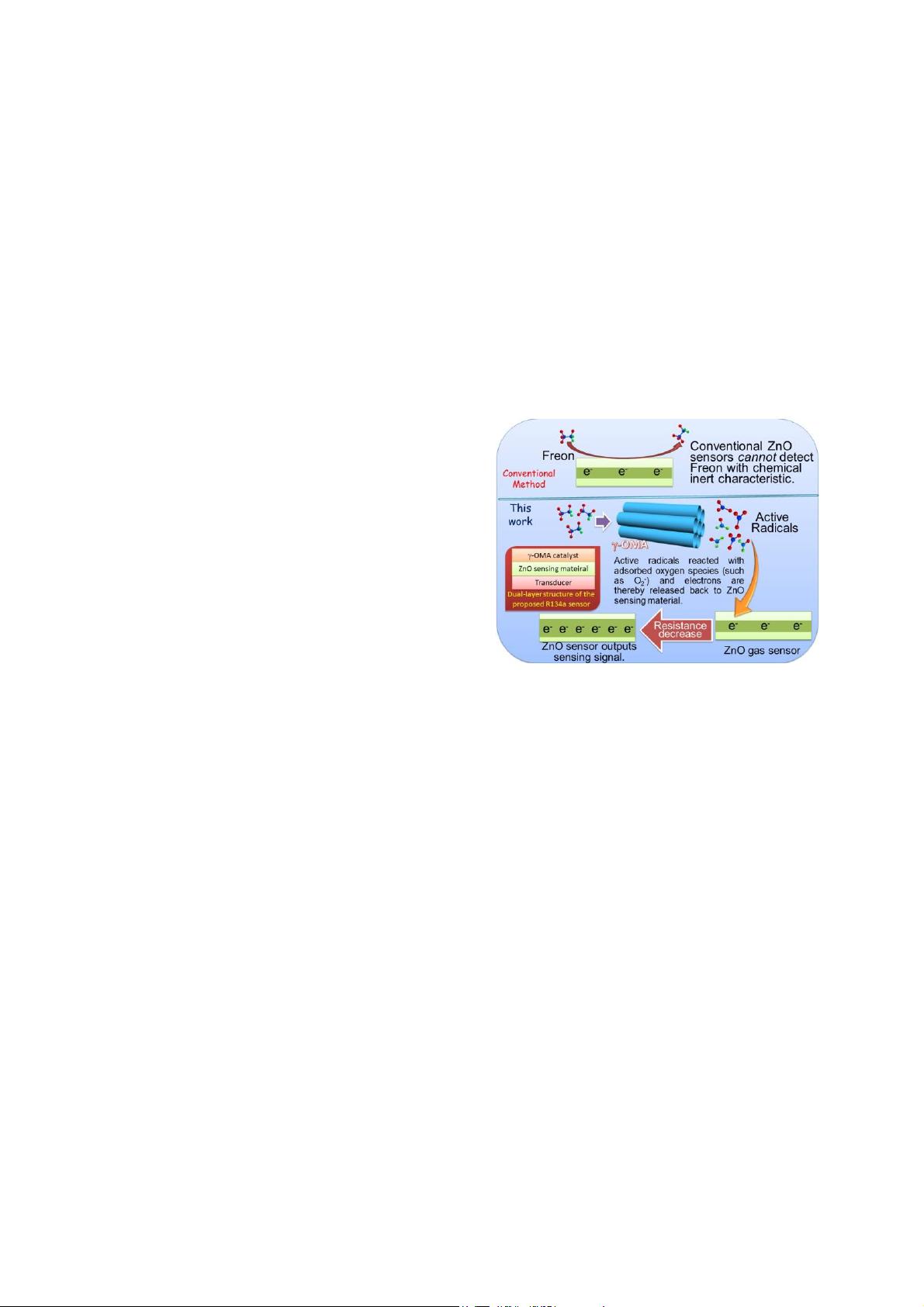

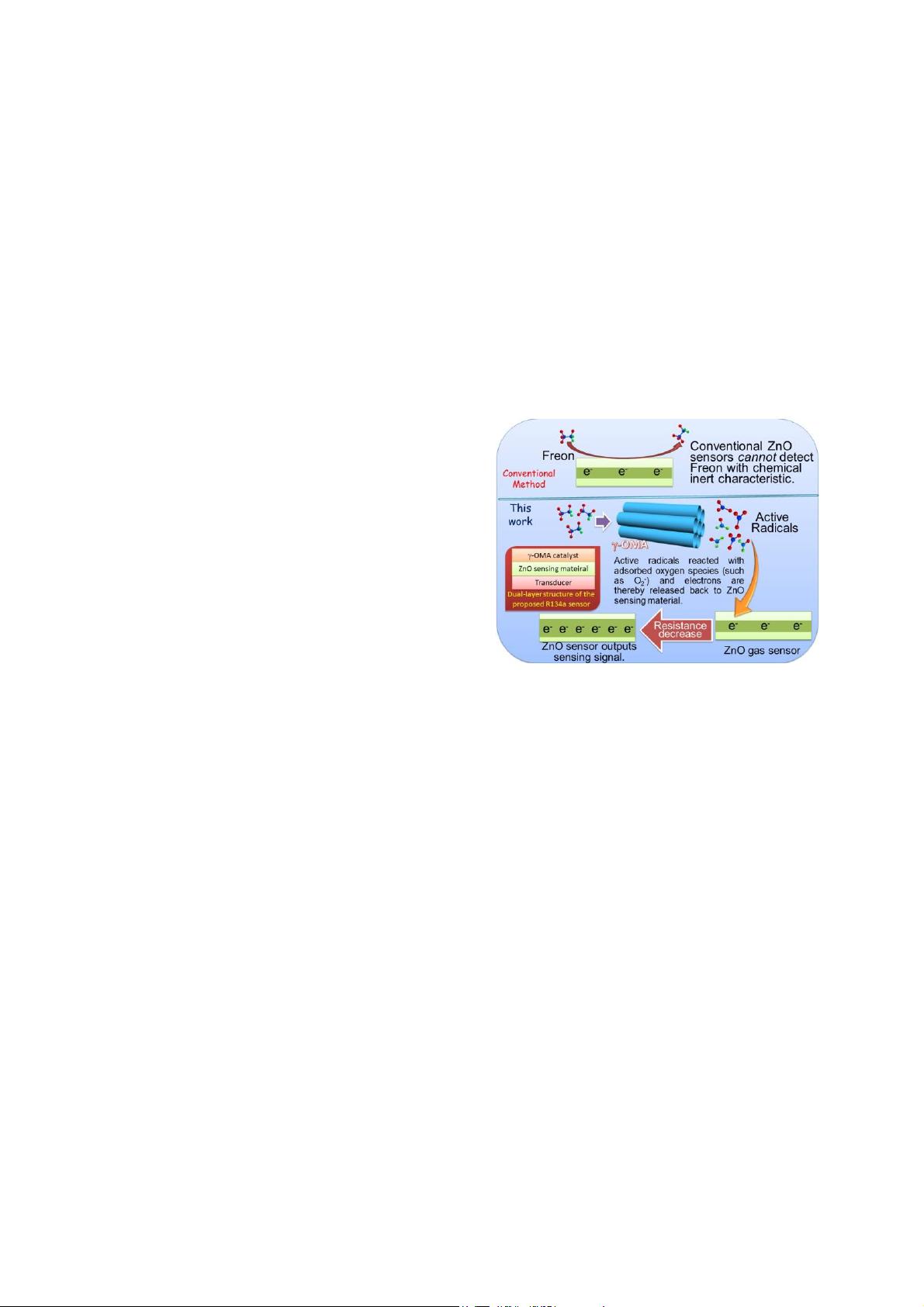

Figure 1: Schematically illustration shows the working

principle of the proposed sensor to inert gas of Freon.

Compared with the conventional ZnO sensor,

gamma-phase ordered mesoporous alumina (

J

-OMA)

catalyst is firstly employed to transform Freon into

radicals. Then, the active radicals can be easily detected

by ZnO sensor.

In this study, we find that gamma-phase ordered

mesoporous alumina (J-OMA) exhibits good catalytic

performance to decompose inert Freon R134a molecules.

With the help of J-OMA catalyst, a dual-layer

chemiresistor sensor is designed to detect Freon R134a: i)

nonconductive J-OMA is employed to decompose R134a

to some detectable substances and, ii) ZnO nanowires

(NWs) are used as semiconductor-type sensing material to

detect the produced species. Thus, the sensing response of

ZnO sensor is mainly determined by the produced

intermediate substances. To optimize the sensing

material/catalyst and to elucidate the sensing mechanism,

qualitative identification of the intermediates becomes the

key technology. Herein, on-line mass spectrum (on-line

MS) is used to identified the produced substances in the

exhaust gas. Some sensing products, which cannot be

analyzed on-line, are introduced to special adsorbent and

further off-line identified by GC-MS (Gas

Chromatography-Mass Spectrometer). Fig. 1

schematically shows the advantage of our dual-layer

chemiresistor sensor over the conventional method.

978-1-5386-4782-0/18/$31.00 ©2018 IEEE 920 MEMS 2018, Belfast, Northern Ireland, UK, 21-25 January 2018